Content Menu

● Introduction

● Thailand's Cake Box Industry Overview

● Common Types of Cake Boxes Provided by Thai Manufacturers

● In-Depth: Cake Box Manufacturing Process

● Leading Cake Box Manufacturers and Suppliers in Thailand

>> Sunshine Packinway

>> Royalpaper

>> Packinway

>> Other Noteworthy Suppliers

● Advantages of Choosing Thai Cake Box Manufacturers and Suppliers

● Sustainability Trends in Thai Cake Box Manufacturing

● Enhancing Bakery Branding Through Packaging

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What types of cake boxes can I customize with Thai manufacturers?

>> 2. How do Thailand cake box suppliers ensure product quality?

>> 3. Can I request OEM services for branded cake boxes?

>> 4. What is the typical lead time for cake box orders from Thailand?

>> 5. Are environmentally friendly materials used in cake box manufacturing?

● Citations

Introduction

Thailand is rapidly emerging as a global center for cake box manufacturers and suppliers, serving bakeries, wholesalers, and brands worldwide. The country's packaging sector is renowned for combining high-quality craftsmanship, advanced technology, and eco-conscious practices to provide innovative cake box solutions. Specialized manufacturers produce a wide variety of cake boxes, including custom designs, transparent displays, and eco-friendly options, that enhance bakery branding and product appeal. This article presents an in-depth look at the top cake box manufacturers and suppliers in Thailand, detailing the types of boxes offered, the manufacturing process, customization options, and sustainability trends.

Thailand's Cake Box Industry Overview

The cake box industry in Thailand has grown substantially in recent years, driven by increasing global demand for premium bakery packaging. Thai manufacturers utilize food-grade materials and sophisticated printing technologies to produce high-quality cake boxes designed for durability, protection, and visual appeal. From small, bespoke artisanal bakeries to large-scale commercial clients, Thai cake box manufacturers provide tailored packaging solutions with efficient lead times and competitive pricing.

With Thailand's strategic location and efficient logistics infrastructure, manufacturers easily ship orders worldwide. The sector reflects strong expertise in design, printing technology, and sustainable materials, offering superior packaging options that meet international standards.

Common Types of Cake Boxes Provided by Thai Manufacturers

Thai cake box manufacturers produce a wide array of packaging types, each designed to suit different bakery products and branding needs:

- Cardboard Cake Boxes: Made with sturdy art card or cardboard, available in various sizes and finishes, including gloss and matte varnish, with options for 4-color offset printing to showcase logo and design.

- Transparent Plastic Cake Boxes: Crafted from food-safe PET or PVC materials, these boxes provide excellent visibility, allowing customers to see the cake while protecting it.

- Windowed Cake Boxes: A hybrid option featuring cardboard boxes with plastic windows for partial product visibility.

- Eco-Friendly Cake Boxes: Made from recycled, biodegradable, or FSC-certified paper materials to meet sustainability expectations.

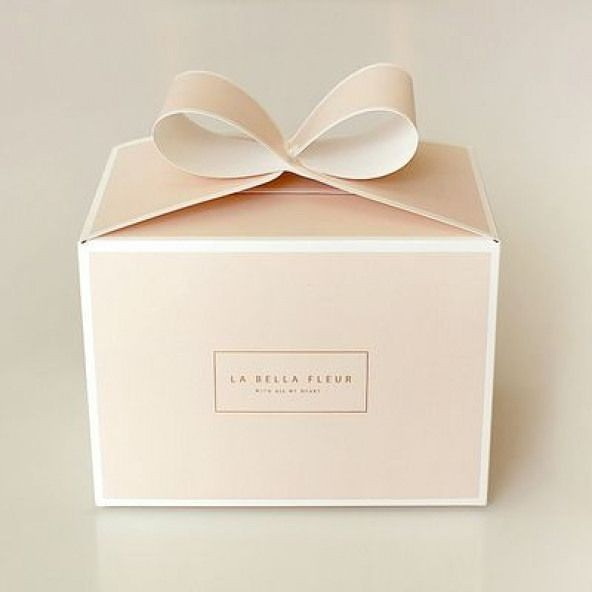

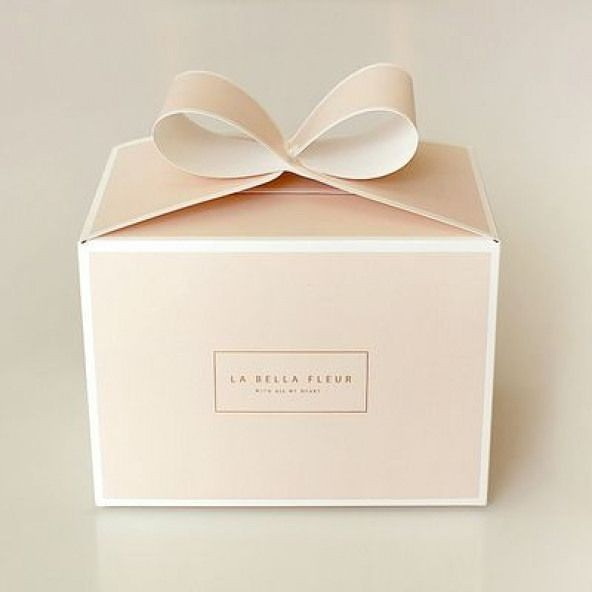

- Custom Printed and Embossed Boxes: Offering hot stamping, embossing, debossing, foil stamping, and spot UV coating to create luxurious, branded packaging.

In-Depth: Cake Box Manufacturing Process

Understanding the manufacturing process highlights the care and precision invested by Thai manufacturers:

1. Raw Material Preparation: Use of high-quality, food-grade cardboard or plastic materials, treated for safety and hygiene.

2. Printing: Advanced machines print customer artwork onto the raw material, ensuring vibrant colors and sharp designs through offset or digital printing methods.

3. Die-Cutting: Printed sheets are die-cut into precise shapes and sizes according to pre-designed templates.

4. Assembly: The cut materials are folded, glued, and pressed to form the final box shape, ready for packing.

5. Quality Inspection: Each finished box undergoes thorough inspection for size accuracy, printing quality, structural integrity, and safety standards.

6. Packaging & Shipping: Approved boxes are packed and shipped to clients globally with attention to preventing damage during transit.

This detailed process ensures consistent, high-quality cake box production with optimized performance for bakery products.

Leading Cake Box Manufacturers and Suppliers in Thailand

Sunshine Packinway

Sunshine Packinway specializes in transparent cake boxes made from food-grade plastics like PET, accommodating customized sizes, colors, and designs. They provide free design support, rapid prototyping, and comprehensive OEM services that align perfectly with bakery branding and functional demands. Their eco-friendly practices and material safety certifications ensure product reliability.

Royalpaper

Royalpaper is a well-known producer of high-quality cardboard bakery boxes with full-color offset printing. They offer a variety of sizes from mini pastry boxes to large cake packaging, including varnished coatings and window-cut options. Their production timeline is efficient, and they provide die-cut molds free for clients, making them a cost-effective choice for large orders.

Packinway

Packinway focuses on transparent plastic cake boxes designed to maximize product presentation. Their product range includes round, square, and multicolored transparent boxes with customizable printing options including logos and hot stamping. Bulk order discounts and sample provisions make Packinway attractive for wholesale and international customers.

Other Noteworthy Suppliers

Other Thai companies provide all-around cake packaging needs, including biodegradable options, intricate hot stamp finishes, and eco-conscious materials. Many offer flexible MOQ policies, allowing small bakers to order custom boxes at competitive prices while large brands benefit from scalable production.

Advantages of Choosing Thai Cake Box Manufacturers and Suppliers

- Customization Flexibility: From dimensions, materials, and printing to special finishes like embossing and foil stamping, customization meets diverse branding needs.

- Competitive Pricing: Efficient production technology and local sourcing maintain affordability even for small-scale orders.

- Quality and Compliance: Use of food-grade, durable, and environmentally responsible materials ensures safety and high product protection.

- Advanced Printing Techniques: Applying offset, digital printing, and finishing technologies ensures eye-catching designs with consistent color reproduction.

- Sustainability Commitment: Many manufacturers prioritize recycled materials and biodegradability aligned with global ecological goals.

- Global Shipping: Well-established logistics enable timely delivery worldwide with good packaging for safe transit.

Sustainability Trends in Thai Cake Box Manufacturing

Sustainability is a key focus area for many Thai cake box suppliers. Efforts include using:

- Recycled and recyclable paperboard

- Biodegradable plastic alternatives such as PLA coatings

- FSC-certified packaging materials

- Energy-efficient manufacturing processes

- Reduced waste production and minimized environmental footprint

These initiatives not only satisfy eco-conscious clients but also enhance the reputation of bakeries adopting green packaging.

Enhancing Bakery Branding Through Packaging

Custom cake boxes are powerful marketing tools that create a memorable unboxing experience. By incorporating logo embossing, coherent color schemes, and premium finishing techniques, bakeries can elevate their brand perception. Transparent and windowed boxes foster buyer confidence by showcasing product quality and freshness. Packaging thus becomes an integral part of customer engagement and loyalty.

Conclusion

Thailand stands out as a premier hub for cake box manufacturers and suppliers, offering a vast array of high-quality, customizable, and sustainable packaging solutions. Combining advanced production technology with skilled craftsmanship, Thai suppliers meet the exacting standards of global bakery businesses. Whether needing transparent display boxes or beautifully printed cardboard packaging, bakeries and wholesalers benefit from Thailand's expertise, competitive pricing, and timely logistics. Leveraging these partners ensures safe transportation, product protection, and enhanced brand appeal for baked goods.

Frequently Asked Questions (FAQ)

1. What types of cake boxes can I customize with Thai manufacturers?

You can choose from cardboard cake boxes, transparent plastic boxes, windowed boxes, and environmentally friendly biodegradable options. Additional customizations include printing logos, embossing, and special coatings.

2. How do Thailand cake box suppliers ensure product quality?

Suppliers maintain strict quality control through raw material inspection, continuous production monitoring, and final product testing. Many hold ISO certifications and comply with food safety regulations.

3. Can I request OEM services for branded cake boxes?

Yes, most manufacturers offer comprehensive OEM services including design support, prototyping, production, and logistics tailored to your branding needs.

4. What is the typical lead time for cake box orders from Thailand?

Lead times generally range from 1 to 3 weeks depending on order size, customization degree, and production schedules. Expedited services may be available.

5. Are environmentally friendly materials used in cake box manufacturing?

Yes, many Thai cake box manufacturers incorporate recycled paper, biodegradable plastics, and FSC-certified materials to meet eco-label standards and consumer demand for sustainability.

Citations

[1](https://www.cake-board.com/news/how-to-make-a-cake-box/)

[2](https://royalpaper.co.th/en/bakery-box/)

[3](https://www.maibaopak.com/reliable-cake-box-manufacturer-with-custom-solutions-product/)

[4](https://www.packinway.com/custom-transparent-cake-box-wholesale/)

[5](https://scppackaging.com)

[6](https://seasongroup.co.th/en/box-packaging)

[7](https://www.alibaba.com/showroom/thailand-cake-box.html)

[8](https://www.sunecobox.com/packaging-boxes-thailand/)

[9](https://www.cake-board.com/cake-box-with-separate-lid/)

[10](https://www.databridgemarketresearch.com/reports/global-cake-box-market)