Tote Bags Categories

Paper bags are versatile products used in various industries and applications due to their eco-friendly nature and durability. They are classified into several types based on different criteria such as materials, construction, and usage:

1.Based on Materials

●Kraft Paper Bags: Made from kraft paper, these are strong and recyclable. They come in various thicknesses and are commonly used for shopping bags, grocery bags, and packaging.

●Recycled Paper Bags: Produced from recycled paper materials, these bags are environmentally friendly and contribute to waste reduction efforts. They are used similarly to kraft paper bags but have a lower environmental impact.

2.Based on Construction

●Flat Paper Bags: Simple bags made from a single sheet of paper, folded and glued. They are often used for small items, gifts, or fast food takeaways.

●SOS (Self-Opening Sack) Bags: These have a square bottom and can stand upright, making them suitable for groceries, merchandise, and food packaging.

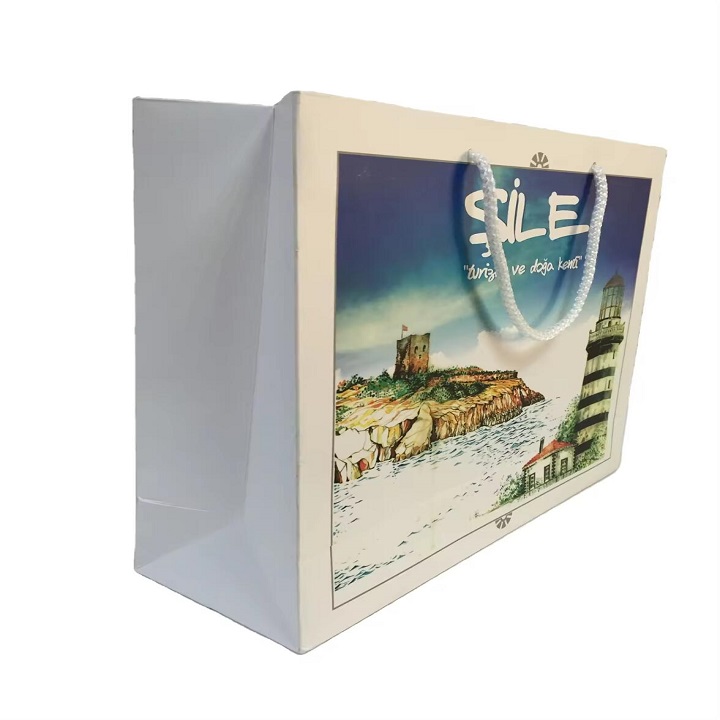

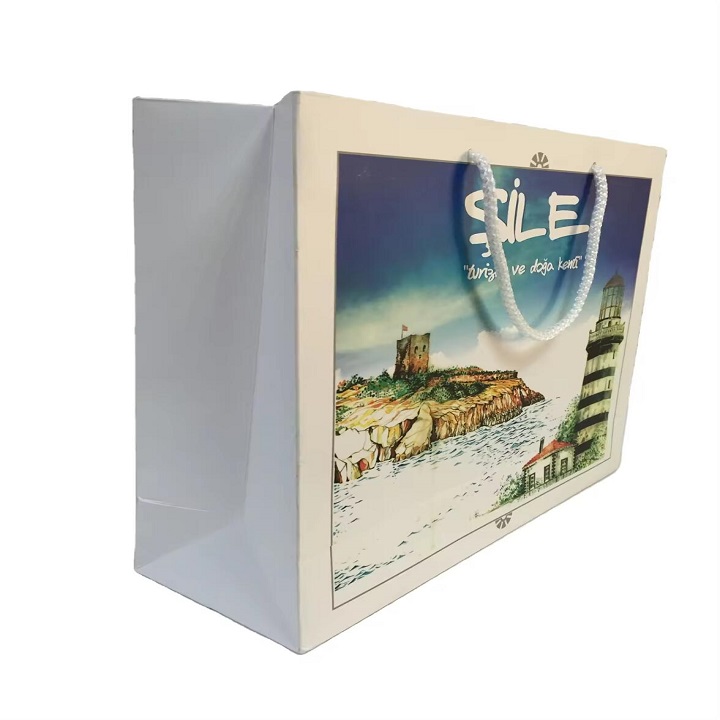

●Twisted Handle Paper Bags: These have twisted paper handles attached to the top of the bag, providing a comfortable carrying option. They are commonly used in retail and branding purposes.

3.Based on Usage

●Retail Paper Bags: Designed for retail environments, these bags often feature customized printing or branding and are used to carry purchased items.

●Food Service Bags: Specifically designed for carrying food items, these bags are often grease-resistant and safe for direct food contact.

●Promotional Paper Bags: Customized with logos or designs, these bags are used for promotional events, conferences, and giveaways.

4.Specialty Paper Bags

●Luxury Paper Bags: High-end bags made from premium materials, often featuring reinforced handles, elaborate designs, and luxurious finishes.

●Wine Bottle Bags: Designed to carry wine bottles safely, these bags may include dividers or extra padding to prevent breakage.

●Medical Paper Bags: Used in medical settings for specimen collection or as biohazard waste bags, they are designed to meet specific health and safety standards.

5.Environmental Characteristics

●Compostable Paper Bags: Made from biodegradable materials, these bags break down naturally without harming the environment.

●Waterproof Paper Bags: Treated with waterproof coatings, these bags are suitable for carrying items that need protection from moisture.

FAQs About Tote Bags

1. What types of paper bags do you offer?

We offer various types of paper bags, including: Handle paper bags,Flat bottom paper bags (suitable for food and retail),Gift paper bags,Eco-friendly paper bags,Custom printed paper bags.

2. Can I customize my paper bags?

Yes, we provide custom printing services where you can customize the size, color, and printing design of your paper bags. Please contact our customer service team for more information on customization options and pricing.

3. What is the minimum order quantity for paper bags?

The minimum order quantity varies depending on the type of paper bag and your customization requirements. Generally, we offer flexibility based on your needs. Please contact our sales team for specific minimum order quantity details.

4. Are your paper bags environmentally friendly?

Yes, we offer environmentally friendly options for paper bags, including recyclable and biodegradable materials. We are committed to reducing environmental impact through the use of sustainable materials and promoting eco-friendly practices.

5. Do you offer discounts for large volume orders?

Yes, we provide discounts for bulk orders based on quantity and customization requirements. Please contact our sales team for the best pricing and service options for large volume orders.

6. How soon can I receive my paper bag order?

Delivery times depend on your specific order requirements, including custom design and shipping method. Typically, we process orders promptly and aim to provide the fastest possible delivery times. Please contact our customer service for a detailed estimate of delivery times.

7. Where can I find more information about paper bags?

You can visit our website or directly contact our customer service team for detailed information on paper bag products, customization options, and services. We are here to assist you with any further inquiries or assistance you may need.

8. Can our paper bags be used for food packaging?

Yes, we offer paper bags that meet food safety standards and are suitable for packaging food and other consumer goods. Our food-grade paper bags are designed to ensure safety and hygiene.

9. Where can we view samples or request samples?

You can contact our customer service team to request samples or arrange to view existing samples. We are happy to provide the samples you need for evaluating quality and design.

10. What is the durability of the paper bags?

Our paper bags are made from high-quality materials to ensure durability and strength. Different types of paper bags have varying levels of durability, and we can provide options that suit your needs.

The Production Processes for Custom Tote Bags

1. Design and Planning:

The process of crafting custom tote bags commences with meticulous designing, encompassing the precise determination of the tote bag's size, shape, handle type, and any bespoke, custom features that set it apart.

A comprehensive technical specification is then formulated, thoroughly outlining requirements such as exact measurements, paper type selection, intricate printing details, and an array of finishing options tailored specifically for custom tote bags.

2. Material Selection:

The selection of paper for custom tote bags is a deliberate process, guided by the bag's intended purpose, the necessary strength requirements, and eco-conscious environmental considerations.

Popular choices encompass kraft paper for its durability, recycled paper for sustainability, or specialty papers that cater to high-end, customized tote bag applications.

3. Cutting and Shaping:

Large rolls of carefully selected paper undergo precise cutting to conform to the specified size and shape of the custom tote bags, adhering strictly to the unique design specifications.

This vital process is often automated to ensure both efficiency and unparalleled precision in the shaping of each and every custom tote bag.

4. Printing:

Should the custom tote bags necessitate personalization, this pivotal step involves the artful addition of logos, captivating designs, or bespoke text that brings the vision to life.

A variety of printing techniques are employed, including flexography for cost-effective large runs, offset printing for exceptional print quality, or digital printing for quick turnaround times and smaller, more customized batches of custom tote bags.

5. Die Cutting:

The printed paper sheets undergo die-cutting specifically tailored for custom tote bags, meticulously shaping the bags' unique contours, including the handles and any distinctive, custom features that set them apart.

6. Folding and Gluing:

The precisely cut paper is then folded along pre-scored lines, meticulously forming the structured foundation of each custom tote bag. The adhesive is applied with precision to designated areas, ensuring a seamless assembly process that results in sturdy, well-constructed custom tote bags.

7. Handle Attachment:

In accordance with the individual design specifications, handles crafted from rope, ribbon, or paper are expertly attached to the custom tote bags, enhancing their functionality and aesthetic appeal.

8. Quality Control:

Each and every custom tote bag undergoes rigorous inspection, meticulously examining for any imperfections in printing, die-cutting, folding, and overall construction. This meticulous step guarantees that the final product exceeds the specified quality standards, ensuring customer satisfaction.

9. Finishing:

To further elevate the durability and visual appeal of the custom tote bags, additional finishing touches such as lamination, varnishing, or specialized coatings may be applied, tailored to the specific requirements of the design.

10. Packaging and Shipping:

Once the custom tote bags have been meticulously crafted and finished, they are carefully counted, neatly bundled, and securely packaged for shipping. With great care, they are dispatched to the awaiting client or designated distribution centers, ready to make their mark in the world.

What A Custom Tote Bags Is Used For?

1. Retail Packaging:

One of the most common uses for custom tote bags is in retail stores.

Clothing stores, boutiques, bookshops, and gift shops often use branded tote bags to enhance their brand image and provide customers with a convenient way to carry their purchases.

2. Food Service:

Restaurants, bakeries, and cafes use custom tote bags for takeout and delivery orders.

These bags can be designed to keep food warm and prevent spills, while also promoting the establishment's brand.

3. Gift Packaging:

Custom tote bags are popular for gift-giving, especially in high-end retail or for special occasions.

They can be designed with elegant prints, patterns, or embellishments to enhance the gift-giving experience.

4. Event Promotion:

Companies often use custom tote bags at trade shows, conferences, or promotional events to distribute marketing materials or free samples.

These bags serve as walking advertisements, increasing brand visibility.

5. Eco-Friendly Shopping:

With increasing environmental awareness, many consumers and businesses are opting for reusable custom tote bags as an alternative to plastic.

These bags are often sturdier and can be used multiple times, reducing waste.

6. Product Packaging:

Some manufacturers use custom tote bags as primary packaging for their products, especially for items like coffee, tea, or artisanal foods.

These bags can be designed with features like resealable tops or windows to showcase the product.

7. Corporate Gifting:

Companies use custom tote bags to package and present corporate gifts, enhancing the perceived value of the gift and reinforcing brand identity.

8. Luxury Retail:

High-end brands often use premium custom tote bags to reflect the quality and exclusivity of their products.

These bags often feature high-quality materials, intricate designs, and special finishes.

9. Healthcare and Pharmacy:

Pharmacies and healthcare providers use custom tote bags to package medications and medical supplies, often with specific designs to ensure privacy and provide important information.

10. Educational Institutions:

Schools, colleges, and universities use custom tote bags for distributing course materials, merchandise, or welcome packages to students.

11. Non-Profit Organizations:

Charities and non-profits use custom tote bags for fundraising events, to distribute informational materials, or as part of awareness campaigns.

12. Wine and Spirits:

Liquor stores and wineries often use specially designed custom tote bags to package bottles, providing both protection and branding.

|  |  |

Gift Bags

| Liquor & Wine Bags

| Paper Shopping Bags

|