Content Menu

● Understanding Die Cut Stickers

● Why France Is a Strategic Market

● Core Services of Leading Suppliers

● Materials and Printing Technologies

● Applications in French and European Markets

● OEM and Private Label Opportunities

● Shenzhen XingKun as an International OEM Partner

● Quality Control and Consistency

● Sustainability and Eco‑Friendly Choices

● Design and Preparation Tips

● Lead Time, MOQ, and Pricing

● How to Select the Right Supplier

● Conclusion

● FAQ

>> 1. What makes die cut stickers different from regular stickers?

>> 2. Are die cut stickers suitable for outdoor use?

>> 3. Can small businesses order low quantities from manufacturers and suppliers?

>> 4. How can brands ensure accurate colors and cutting lines?

>> 5. Why should brands consider working with an OEM partner like Shenzhen XingKun?

Die Cut Stickers manufacturers and suppliers in France support a wide range of European brands with customized, high‑quality stickers for packaging, promotion, and labeling. These Die Cut Stickers Manufacturers and Suppliers combine advanced printing, precise cutting, and diverse materials to meet the needs of startups, wholesalers, and established producers. Working with reliable partners in France and abroad makes it easier for businesses to obtain consistent, durable, and visually appealing die cut stickers for every type of product.

Understanding Die Cut Stickers

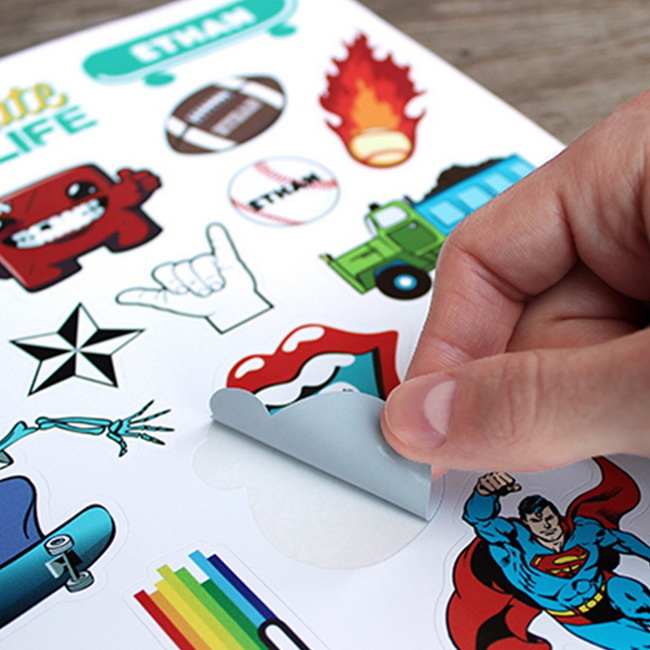

Die cut stickers are stickers that follow the exact contour of a design or logo rather than a standard rectangle, circle, or square. This custom shape allows brand owners to create unique visual effects and stronger recognition on packaging, products, and promotional materials. Because the cutting line follows the artwork, die cut stickers look professional and tailored, which is especially important for brands that want to stand out on shelves or online marketplaces.

Die Cut Stickers Manufacturers and Suppliers typically offer these stickers in vinyl, paper, and synthetic films, along with options for gloss, matte, and specialty finishes. Many suppliers also provide transparent or clear materials so that only the printed artwork is visible when applied. In addition, professional manufacturers may offer extra protection through lamination or coating to make die cut stickers resistant to water, UV light, scratching, and frequent handling.

Why France Is a Strategic Market

France is one of the most influential markets in Europe for design, fashion, cosmetics, food, and wine, all of which rely heavily on branding and packaging. For these sectors, die cut stickers are a convenient and versatile way to decorate bottles, boxes, pouches, and promotional items. Die Cut Stickers Manufacturers and Suppliers serving France must meet high expectations for color accuracy, print clarity, and material quality, because French consumers are accustomed to refined aesthetics and well‑designed packaging.

Another key factor is regulation. Products sold in France and across the European Union must follow specific labeling rules, including ingredient lists, safety warnings, language requirements, and barcode placement. Reliable Die Cut Stickers Manufacturers and Suppliers help clients comply with these rules by offering precise printing, clear text reproduction, and accurate cutting so that labels fit correctly on containers and packaging. By partnering with experienced suppliers, brands can avoid costly recalls or relabeling issues.

Core Services of Leading Suppliers

Leading Die Cut Stickers Manufacturers and Suppliers usually provide a broad catalog of services that go far beyond basic printing. These often include:

- Custom size and shape: Clients can specify any dimension and outline, from tiny logo stickers to large product labels and decals.

- Variety of materials: Options typically include white vinyl, clear vinyl, coated paper, uncoated paper, and eco‑friendly or PVC‑free films.

- Multiple finishes: Gloss, matte, soft‑touch, and sometimes specialty finishes such as metallic or holographic effects.

- Different delivery formats: Stickers can be delivered as singles, on sheets, on rolls, or on large format backing for easy application.

Many Die Cut Stickers Manufacturers and Suppliers also provide pre‑press services such as file checking, vector path creation, and color optimization. This means clients can send their artwork with confidence, knowing the supplier will flag problems with resolution, color spaces, or bleed before production. Some companies even have design teams that can fine‑tune logos, text, and layouts to improve overall print quality.

Materials and Printing Technologies

Professional Die Cut Stickers Manufacturers and Suppliers rely on several printing technologies, most commonly digital printing and offset printing. Digital printing is ideal for short runs, frequent design changes, and variable data because it allows quick setup and efficient production even for low quantities. Offset printing is more suitable for high‑volume orders where color constancy and cost per unit are critical.

Vinyl remains one of the most popular materials for die cut stickers because it is durable, flexible, and resistant to moisture. High‑quality vinyl die cut stickers work well for outdoor applications, such as vehicle decals, window displays, and equipment labeling. For indoor uses and cost‑sensitive projects, coated paper can be a good choice, especially when stickers are not exposed to harsh conditions. Many Die Cut Stickers Manufacturers and Suppliers also offer laminations and varnishes to extend the life of stickers under demanding conditions.

Applications in French and European Markets

Die cut stickers are used in many different contexts across France and the broader European market. In the food and beverage sector, they adorn jars, bottles, and packaging for gourmet products, craft beverages, and specialty items. For cosmetics and personal care brands, die cut stickers carry logos, product names, and regulatory information on bottles, tubes, and boxes. Retailers use custom stickers for seasonal promotions, sales campaigns, and loyalty programs.

Trade shows, festivals, and cultural events across France also rely on die cut stickers as simple yet powerful promotional tools. Organizers and sponsors distribute branded stickers to attendees, who then apply them to laptops, notebooks, and personal items, effectively extending the event's visibility. Industrial and logistics companies use die cut stickers and labels for barcodes, safety warnings, stock control, and instruction decals, ensuring that operational information is both durable and easy to read.

OEM and Private Label Opportunities

OEM and private label cooperation are crucial for many brands that sell into France but do not operate their own printing facilities. Die Cut Stickers Manufacturers and Suppliers capable of OEM production can print under another company's brand name, follow detailed specifications, and ship neutral packaging directly to distributors or fulfillment centers. This approach is especially attractive to online merchants and wholesalers who want to offer custom sticker products without managing production themselves.

OEM partners typically work with detailed technical documents, including color codes, cutting paths, material specifications, and packaging instructions. They are accustomed to handling repeating orders, product line extensions, and seasonal designs. For clients, partnering with trusted OEM Die Cut Stickers Manufacturers and Suppliers means faster time to market and the ability to scale production as demand increases.

Shenzhen XingKun as an International OEM Partner

Shenzhen XingKun Packing Products Co., Ltd is an example of a professional manufacturer that provides comprehensive OEM solutions for global clients, including those targeting the French market. The company focuses on a wide range of printed products such as display racks, paper boxes, plastic boxes, notebooks, playing cards, flashcards, stickers, labels, and booklets. By combining these capabilities, Shenzhen XingKun can act as both a packaging producer and part of the global network of Die Cut Stickers Manufacturers and Suppliers.

For brands, wholesalers, and producers that sell into France, working with Shenzhen XingKun means consolidating multiple printed components under one supplier. A client can order die cut stickers for product labeling alongside custom boxes, promotional booklets, and other printed materials, simplifying logistics and quality management. With experience in export projects and OEM service, the company understands international expectations regarding print quality, communication, and on‑time delivery.

Quality Control and Consistency

Quality control is one of the most important factors when evaluating Die Cut Stickers Manufacturers and Suppliers. Professional companies use systematic inspections at each production step, starting with file verification and proofing. They check that images meet minimum resolution, that text remains legible at the desired size, and that cutting paths are correctly defined. Many suppliers also provide digital or physical proofs so clients can verify colors and layout before mass production.

During printing and cutting, operators monitor color consistency, registration, and cutting accuracy. Misaligned cuts or color shifts can easily ruin an entire batch of die cut stickers, so reputable manufacturers invest in proper calibration and maintenance of printers and cutting machines. After production, final inspections verify adhesion, surface finish, and packaging quality. This attention to detail ensures that stickers arrive ready for use and meet the brand's standards.

Sustainability and Eco‑Friendly Choices

Sustainability has become a major priority for both clients and Die Cut Stickers Manufacturers and Suppliers, especially in markets like France where environmental awareness is strong. Many suppliers now offer recycled papers, biodegradable materials, and PVC‑free films. These solutions help reduce environmental impact without sacrificing print quality or durability for most applications.

Eco‑friendly inks, such as water‑based or low‑VOC formulations, are also increasingly common. In addition, some manufacturers optimize their production workflows to minimize waste, recycle off‑cuts, and use energy more efficiently. Brands that care about sustainability can request documentation or certifications related to materials and processes, and then communicate this commitment to their own customers through on‑pack messaging and marketing.

Design and Preparation Tips

To get the best results from Die Cut Stickers Manufacturers and Suppliers, careful design preparation is essential. One of the most important steps is defining a clear outline or contour around the artwork. If the shape is too complex or fragile, small details may break during cutting or application. Designers should also make sure there is enough bleed beyond the cutting line to avoid white edges and enough safe margin inside the line to protect important text and graphics.

Text legibility is another key issue. Because many die cut stickers are relatively small, fonts should be large enough and colors should provide sufficient contrast against the background. Thin lines or delicate scripts may look attractive on screen but become difficult to read when printed. Finally, artworks should be provided in print‑ready formats using appropriate color spaces and embedded fonts. Following the technical guidelines provided by Die Cut Stickers Manufacturers and Suppliers helps avoid delays and costly revisions.

Lead Time, MOQ, and Pricing

Lead times and minimum order quantities (MOQ) vary widely among Die Cut Stickers Manufacturers and Suppliers. Some companies focus on very fast production for small quantities, targeting events, independent brands, and small businesses that need quick turnaround. Others specialize in large‑volume orders and recurring production for major retailers and manufacturers. Clients should choose a supplier whose production model matches their own ordering pattern and growth plans.

Pricing is influenced by several factors, including material type, size, number of colors, finishing options, and order volume. Generally, larger quantities reduce the cost per unit, but small batches are still economical when using digital printing. Clients can often optimize costs by adjusting sticker dimensions, choosing appropriate materials rather than over‑specifying, and grouping multiple designs in a single order when possible. Open communication with Die Cut Stickers Manufacturers and Suppliers helps identify the best balance between quality, speed, and budget.

How to Select the Right Supplier

Choosing the right partner among many Die Cut Stickers Manufacturers and Suppliers requires a structured approach. Buyers should first clarify their own requirements, such as indoor or outdoor use, expected lifespan, regulatory constraints, and desired aesthetics. With a clear brief, it becomes easier to evaluate material options and printing technologies. Samples from potential suppliers are extremely helpful, allowing clients to see and feel the difference between various substrates and finishes.

Communication style and service quality are just as important as technical capabilities. A good supplier responds promptly, provides detailed answers, and offers practical suggestions to improve the final result. For international cooperation, language skills, logistics experience, and familiarity with customs procedures are crucial. Long‑term partnerships often deliver the best value, because the supplier becomes familiar with the brand's standards and can anticipate future needs in terms of die cut stickers and other printed items.

Conclusion

Die Cut Stickers Manufacturers and Suppliers in France and around the world play a vital role in modern branding, packaging, and promotion. Their ability to produce custom shapes, use diverse materials, and maintain high print quality helps brands create memorable product experiences and powerful visual identities. Whether a company needs small runs for events or large‑scale OEM production for retail distribution, professional suppliers can tailor solutions to fit different budgets, timelines, and technical requirements.

By working with experienced partners, including international OEM manufacturers like Shenzhen XingKun Packing Products Co., Ltd, brands gain access to integrated solutions that combine die cut stickers with other packaging components. Attention to design details, sustainability goals, and quality control ensures that each sticker performs as expected in its final environment. As competition intensifies across physical and digital marketplaces, investing in well‑designed die cut stickers from reliable manufacturers and suppliers remains a smart strategy for long‑term brand success.

FAQ

1. What makes die cut stickers different from regular stickers?

Die cut stickers are cut to match the exact outline of a design or logo, whereas regular stickers usually follow simple shapes like rectangles or circles. This custom cutting process gives brands more creative freedom, allowing their stickers to mirror product silhouettes, mascots, or unique icons. As a result, die cut stickers look more distinctive and professional, especially when applied to packaging, bottles, or laptops.

2. Are die cut stickers suitable for outdoor use?

Many die cut stickers are suitable for outdoor use when manufactured with durable vinyl, strong adhesive, and protective lamination or coating. These materials help resist moisture, UV exposure, and general wear, making the stickers ideal for vehicles, windows, and equipment. When ordering, clients should clearly state that they need outdoor‑grade products so that Die Cut Stickers Manufacturers and Suppliers can recommend the right combination of materials and finishes.

3. Can small businesses order low quantities from manufacturers and suppliers?

Yes, small businesses can often order low quantities, especially from suppliers that specialize in digital printing and short runs. Many Die Cut Stickers Manufacturers and Suppliers offer flexible minimum order quantities to support startups, creators, and local brands. This flexibility allows new businesses to test designs, packaging concepts, and marketing ideas without committing to large inventories.

4. How can brands ensure accurate colors and cutting lines?

Brands can improve accuracy by providing high‑resolution artwork, using vector files for logos and cutting paths, and following the technical guidelines requested by the supplier. It is helpful to define spot colors or share color references if color consistency is critical across multiple products. Many Die Cut Stickers Manufacturers and Suppliers also offer proofing options, such as digital proofs or printed samples, so clients can check colors and shapes before approving full production.

5. Why should brands consider working with an OEM partner like Shenzhen XingKun?

An OEM partner such as Shenzhen XingKun Packing Products Co., Ltd allows brands to access large‑scale, professional production without investing in their own printing and packaging facilities. Beyond die cut stickers, Shenzhen XingKun can produce display racks, boxes, labels, and other printed items, enabling clients to source multiple components from a single supplier. This integrated approach simplifies project management, improves consistency across different packaging elements, and can reduce overall costs for wholesalers, producers, and brand owners.