Content Menu

● What Makes a Poker Cards Factory Different From a Regular Printing Company?

● Why Customization Is the Heart of Poker Card Manufacturing

● The XingKun Advantage: Quality, Speed, and Global Reliability

● How Does XingKun Ensure Sustainable and Ethical Production?

● The Creative Process: From Idea to Final Deck

● Applications of Custom Poker Cards

● Maintaining Excellence Through Innovation

● Why Clients Around the World Trust XingKun

● Frequently Asked Questions About Poker Cards Factories

>> 1. What is the minimum order quantity for custom poker cards at XingKun?

>> 2. Can I order plastic poker cards instead of paper ones?

>> 3. How long does production usually take?

>> 4. Do you offer design support if I don’t have artwork ready?

>> 5. Can the packaging be fully customized?

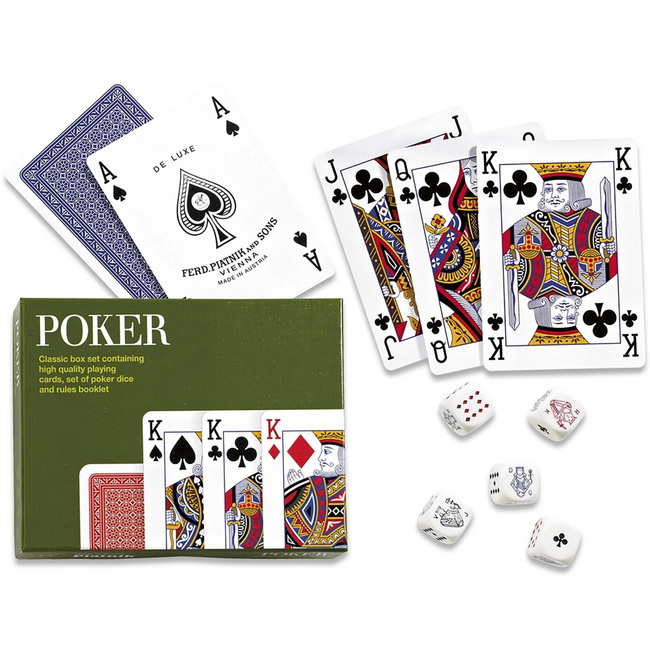

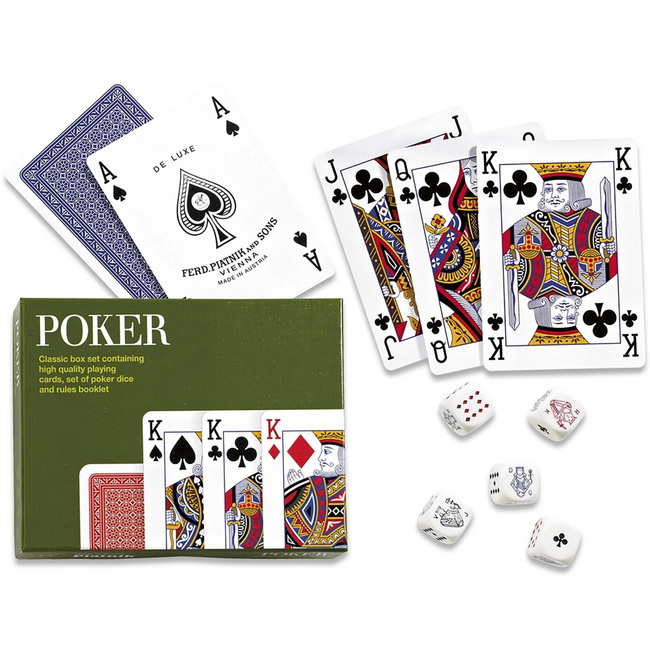

In the competitive world of promotional items, gaming accessories, and entertainment products, custom playing cards stand out as a timeless and versatile choice. They combine practicality, creativity, and brand potential in one compact product. For companies or individuals looking to produce poker cards that truly represent their brand identity, choosing the right poker cards factory is more than just a procurement decision — it’s a partnership for quality, innovation, and reliability.

Among the many manufacturers available, XingKun has established itself as a trusted name in the poker card industry, known for high-quality craftsmanship, flexible customization, and attentive client service. But what exactly sets a professional poker cards factory apart? And how does XingKun help bring your creative vision to life?

What Makes a Poker Cards Factory Different From a Regular Printing Company?

At first glance, printing poker cards may seem similar to printing flyers or brochures. However, professional card manufacturing requires specialized knowledge and machinery that ordinary printing facilities simply don’t have. A poker cards factory focuses exclusively on card production — from selecting the right paper stock to precision cutting, coating, and packaging.

Unlike typical printing services, dedicated poker card factories control every variable that affects playability and durability, including:

Card stock selection: Professional factories use high-quality black core or blue core paper, ensuring opacity and a satisfying weight in hand.

Precision cutting: Cards are machine-cut to exact poker or bridge sizes, eliminating inconsistent edges or rough textures.

Surface coating: Options like glossy varnish, matte lamination, or linen textures enhance shuffle-ability and tactile feel.

Color consistency: Advanced color management systems ensure that your custom artwork looks uniform across thousands of decks.

Packaging integration: From tuck boxes to luxury magnetic cases, everything can be produced in-house for brand consistency.

XingKun’s facilities combine advanced production equipment with skilled technicians, allowing seamless coordination from design to final shipment. This ensures every deck reflects not just your design, but your standards.

Why Customization Is the Heart of Poker Card Manufacturing

Customization defines the modern poker cards factory business model. Whether you are a game developer creating your own card game, a corporate client designing promotional items, or an artist releasing collectible decks, customization allows a level of personal expression impossible with standard decks.

XingKun specializes in turning customer ideas into tangible, high-quality products. Every order is treated as a creative collaboration, offering flexibility in the following areas:

Card size and thickness: Choose between standard poker (63×88mm) or bridge (57×89mm) formats, or opt for a completely unique dimension.

Material options: From paper decks for promotional giveaways to PVC or plastic decks for long-term durability.

Printing finish: Glossy, matte, linen, or custom embossing options to match your project’s look and feel.

Full design support: The design team can adapt artwork, refine layouts, and apply bleed margins to ensure professional printing results.

Packaging choices: Custom tuck boxes, window boxes, rigid boxes, or even custom sleeves and wraps.

For clients, this means creative control without technical stress. XingKun’s customization process is simple yet comprehensive: they turn a design sketch or digital file into a finished deck ready for retail or promotion.

The XingKun Advantage: Quality, Speed, and Global Reliability

When choosing a poker cards factory, clients care most about three factors — quality, production speed, and reliable delivery. XingKun delivers excellence in all three through a refined workflow and customer-focused philosophy.

1. Premium Materials and Craftsmanship

Every deck begins with carefully selected raw materials. XingKun sources high-grade paper and coatings, ensuring superior print quality, vibrant colors, and resistance to wear. The cards maintain excellent flexibility and thickness balance, providing that smooth, professional shuffle most users expect.

2. Advanced Printing Technology

Using cutting-edge offset printing machines, XingKun achieves crisp details and color accuracy that meet international standards. The specialized finishing process prevents ink smudging, warping, or fading — even with heavy use.

3. Flexible Production Scale

Whether producing small promotional runs or bulk orders for global brands, XingKun can adjust capacity quickly without compromising efficiency. This scalability makes them ideal for startups, designers, or large-scale corporate buyers alike.

4. On-Time Delivery

A strong logistics network streamlines shipping worldwide. By integrating packing, inspection, and export documentation under one roof, XingKun eliminates bottlenecks and keeps timelines transparent.

5. Customer-Focused Communication

XingKun’s customer service team supports every stage of the process — from artwork confirmation to factory testing. Their multilingual communication and prompt updates ensure that international clients always stay informed and confident in the outcome.

How Does XingKun Ensure Sustainable and Ethical Production?

In recent years, buyers have become more aware of sustainability and ethics in manufacturing. A responsible poker cards factory must balance performance and environmental care. XingKun recognizes this and operates with a commitment to eco-conscious practices.

Some of their eco-friendly measures include:

Non-toxic inks: All inks used are soy- or water-based, minimizing chemical residue.

Recyclable materials: Most paper and packaging options are FSC-certified, supporting responsible forestry.

Reduced waste production: Advanced laser cutting helps maximize material usage and reduce offcuts.

Energy efficiency: Modern equipment consumes less water and energy while maintaining high print quality.

For clients who prioritize sustainability, these values add depth to the creative process — delivering products that not only look excellent but also feel responsible.

The Creative Process: From Idea to Final Deck

Ordering custom poker cards may sound daunting, but XingKun’s process is structured for efficiency and clarity. Their step-by-step workflow ensures transparency and quality control at every milestone.

Step 1: Consultation and Design Brief

Clients share their ideas, target audience, and artwork guidelines. The design team advises on technical details like bleed size, safe zones, and template formats.

Step 2: Material and Finish Selection

Choose paper type, texture, coating, and packaging preferences. Samples are available upon request for physical inspection.

Step 3: Proofing and Confirmation

Before mass production, XingKun provides digital or physical proofs so clients can verify accuracy.

Step 4: Production and Quality Testing

Once approved, the order enters full production. Cards are inspected through multi-stage quality control, including color checks, edge alignment, and durability testing.

Step 5: Packaging and Shipping

Decks are packaged according to client requirements, then shipped directly to global destinations with all required documentation.

Applications of Custom Poker Cards

Working with a specialized poker cards factory opens endless creative opportunities. Beyond traditional casino decks, these products serve diverse functions across multiple industries:

Corporate branding: Custom decks serve as elegant promotional giveaways or client gifts.

Retail products: Artists and creators can design collectible decks with themed artwork for sale.

Event souvenirs: Poker cards make memorable mementos for weddings, festivals, or conferences.

Educational tools: Customized decks can illustrate concepts, vocabulary, or math problems creatively.

Tabletop games: Independent designers often use poker-sized cards for prototypes and full games.

With XingKun’s expertise, each of these applications can be produced to meet aesthetic and functional goals.

Maintaining Excellence Through Innovation

The playing card industry evolves constantly. Printing technologies, consumer preferences, and design trends shift rapidly. XingKun stays ahead of these changes by investing in research and innovation.

Their R&D team explores new materials like waterproof plastic and metallic foil finishes. They also enhance digital prepress tools to reduce turnaround times and increase design flexibility.

This spirit of innovation transforms XingKun from a simple card printer into a strategic manufacturing partner. By combining tradition with technology, they continually raise the bar for what a poker cards factory can achieve.

Why Clients Around the World Trust XingKun

Many clients return to XingKun repeatedly, not only because of the exceptional product quality but also the experience of collaboration. The company’s philosophy centers on three guiding pillars:

Honesty: Transparent pricing, clear communication, and full respect for client confidentiality.

Precision: Every deck is handled with strict quality standards, from print calibration to packaging inspection.

Artistry: Beyond technical execution, XingKun embraces design as an art form — ensuring each deck tells a story.

Whether serving small creative studios, schools, or international enterprises, the company adapts to unique customer needs with equal professionalism.

Frequently Asked Questions About Poker Cards Factories

1. What is the minimum order quantity for custom poker cards at XingKun?

XingKun offers flexible order quantities to accommodate both small creative projects and bulk commercial runs. The minimum quantity depends on the design complexity and packaging type, typically ranging from 100 to 500 decks.

2. Can I order plastic poker cards instead of paper ones?

Yes. XingKun provides both paper and 100% plastic decks. Plastic cards are waterproof, durable, and ideal for casinos, outdoor events, or frequent-use environments.

3. How long does production usually take?

Standard production time ranges from 7–20 working days after artwork approval, depending on order size and customization level. The company also offers expedited services for urgent requests.

4. Do you offer design support if I don’t have artwork ready?

Absolutely. XingKun’s creative design team can help refine your concept, adjust image resolution, and format your artwork for professional printing.

5. Can the packaging be fully customized?

Yes. Every aspect of the packaging — from box material and finish to printing and shape — can be customized to match your theme or branding requirements.