Content Menu

● Overview of Indonesia's Die Cut Sticker Industry

● Leading Die Cut Stickers Manufacturers and Suppliers

>> PT. Ohtomi

>> Masterlabel

>> PT. Mandiri Cipta Labelindo

>> PT. KK Label Indonesia

>> Cahaya Jakarta

>> PT. Naxis Label Indonesia

● Types of Die Cut Stickers Produced in Indonesia

● Key Features Offered by Indonesian Manufacturers

● OEM and Private Label Services

● Quality Assurance and Certifications

● Typical Applications for Indonesian Die Cut Stickers

>> Brand and Product Labels

>> Promotional and Event Stickers

>> Industrial and Logistics Stickers

>> Apparel and Fashion Accessories

>> Security and Anti‑Counterfeit Uses

● Trends Shaping the Indonesian Die Cut Sticker Market

● How Overseas Buyers Can Work with Indonesian Suppliers

>> Clarify Specifications

>> Request Samples and Prototypes

>> Evaluate Communication and Service

>> Consider Logistics and Lead Times

● Comparing Key Factors When Selecting a Supplier

● Positioning of OEM Providers from China

● Conclusion

● FAQ

>> 1. What are die cut stickers and how do they differ from regular labels?

>> 2. Why choose Indonesian die cut stickers manufacturers and suppliers for OEM projects?

>> 3. What information should I provide when requesting a quote for die cut stickers?

>> 4. Can Indonesian suppliers handle eco-friendly or sustainable sticker projects?

>> 5. How can I ensure consistent quality across repeat orders?

Indonesia has become a dynamic hub for custom printing and packaging, especially in the field of Die Cut Stickers manufacturers and suppliers serving global brands, wholesalers, and producers. As demand grows for unique branding, eco-friendly materials, and precise finishing, Indonesian companies are elevating their manufacturing standards to compete internationally. This creates tremendous opportunities for overseas buyers who want reliableDie Cut Stickers Manufacturers and Suppliers that offer OEM and custom services.

Overview of Indonesia's Die Cut Sticker Industry

Indonesia's printing and packaging sector has grown steadily alongside its manufacturing and export industries, making it an attractive base for die cut stickers manufacturers and suppliers targeting both domestic and overseas markets. Many factories now combine traditional printing expertise with modern digital technologies, ensuring competitive pricing without sacrificing quality or flexibility.

Die cut stickers manufacturers and suppliers in Indonesia typically work with clients from retail, e‑commerce, food and beverage, cosmetics, fashion, electronics, and industrial equipment, offering tailored solutions from simple product labels to high-value security and promotional stickers. The industry's strength lies in its ability to integrate printing, die cutting, finishing, and packaging into a complete OEM service package.

Leading Die Cut Stickers Manufacturers and Suppliers

Indonesia has a strong group of professional die cut stickers manufacturers and suppliers that focus on quality, innovation, and efficient service. While their specialties vary, many of them share common strengths such as advanced equipment, experienced technicians, and a strong export orientation.

PT. Ohtomi

PT. Ohtomi is one of Indonesia's most established names in label and sticker production, operating since the early 1970s. As a pioneer in the sector, the company is known for dependable quality, stable color performance, and the ability to handle both large, long-run projects and smaller, highly customized jobs. It serves various industries including FMCG, logistics, retail chains, and industrial manufacturing, and is particularly experienced in producing functional labels that must meet strict technical specifications.

Masterlabel

Masterlabel specializes in high-precision labels and complex applications, making it a valuable partner for brands that need sophisticated die cut stickers rather than simple, rectangular labels. The company's strength lies in advanced printing and finishing technologies such as multi-layer constructions, spot finishes, and security features. It collaborates closely with brand owners to design and produce stickers with tamper evidence, holographic elements, or special coatings designed to prevent counterfeiting or enhance shelf appeal.

PT. Mandiri Cipta Labelindo

PT. Mandiri Cipta Labelindo focuses strongly on the garment and apparel industry, supplying die cut stickers and labels for clothing, accessories, and packaging. It produces size labels, care labels, price tags, barcode stickers, and promotional die cut stickers tailored to fashion and sportswear brands. With deep knowledge of garment industry needs, it offers materials and adhesives that adhere well to textile packaging, hangtags, and retail display surfaces, while maintaining print clarity and durability through transport and handling.

PT. KK Label Indonesia

PT. KK Label Indonesia operates as a comprehensive label and packaging provider, offering pressure-sensitive labels, paper and film stickers, hangtags, and small folding packaging. It invests heavily in quality management and process control, ensuring consistent color, accurate die cutting, and reliable adhesion across multiple production batches. This makes it a strong choice for die cut stickers manufacturers and suppliers serving international brands that require stable, repeatable quality.

Cahaya Jakarta

Cahaya Jakarta has evolved from a small label printer into a full-service provider of stickers and labels for consumer goods, industrial products, and promotional campaigns. The company focuses on flexible production and eco-conscious materials, offering options like recycled paper stocks and low-VOC inks. It is a good fit for brands that require both creative design support and technical advice on materials and adhesives for specific surfaces or conditions.

PT. Naxis Label Indonesia

PT. Naxis Label Indonesia serves fashion, footwear, and lifestyle brands with a wide range of labels and sticker-based branding products. Beyond standard stickers, it provides woven labels, heat transfers, hangtags, and packaging elements that support cohesive branding across physical products and packaging. Its die cut stickers solutions are often integrated with broader brand identity projects, allowing clients to maintain consistent design across all touchpoints.

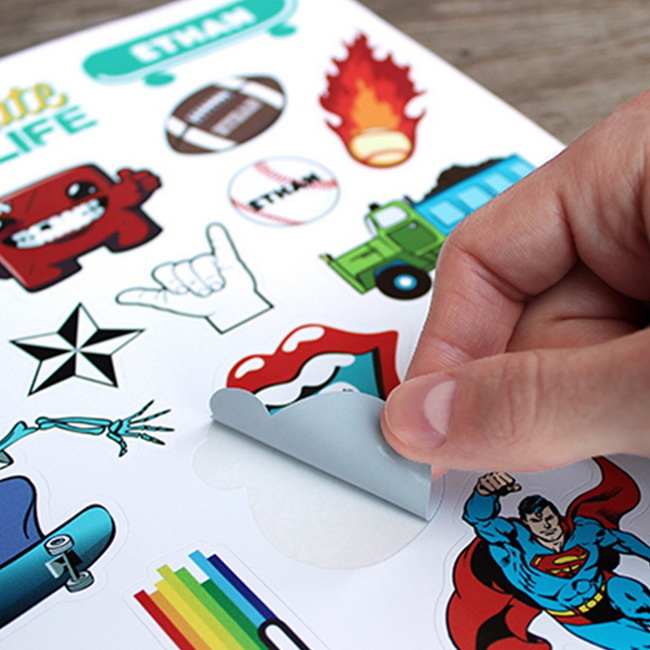

Types of Die Cut Stickers Produced in Indonesia

Die cut stickers manufacturers and suppliers in Indonesia provide many different formats to match diverse applications and budgets. The main categories include:

- Standard paper die cut stickers for general product labeling and barcodes

- Vinyl and BOPP die cut stickers for outdoor use, cosmetics, and chilled or wet environments

- Clear and transparent die cut stickers for minimalistic, “no‑label” branding on bottles and jars

- Metallic and foil stickers for premium packaging and limited editions

- Security stickers with tamper-evident features or serialized codes

- Embossed, textured, or 3D stickers for high-value products and luxury branding

These options can be combined with various adhesives, backing materials, laminations, and surface treatments to create custom solutions for each brand or project.

Key Features Offered by Indonesian Manufacturers

Die cut stickers manufacturers and suppliers in Indonesia typically provide a range of features that enhance value for international clients. These include:

- High-resolution printing using digital, flexographic, or offset technologies for sharp text and vivid color gradients

- Custom shapes and contours that closely follow the design, rather than simple geometric shapes

- Weather and chemical resistance for applications exposed to UV light, moisture, oils, or cleaning agents

- Special finishes such as matte, gloss, soft-touch, or UV spot coatings to match brand image

- Easy-peel formats including sheets, rolls, or individual pieces tailored to manual or automated application

For buyers, these features mean they can obtain not just basic labels, but fully customized die cut stickers that amplify branding and improve user experience.

OEM and Private Label Services

Indonesia is highly competitive in OEM and private label services, and die cut stickers manufacturers and suppliers are no exception. Many factories are structured to function as long-term manufacturing partners, rather than simple one-time vendors, and can integrate with clients' product development processes.

Typical OEM and private label services include:

- Joint development of artwork, color standards, and technical specifications

- Assistance with material selection for different surfaces, temperatures, and usage environments

- Custom die and tooling development for unique shapes and dimensions

- Sample-making and pilot runs before full-scale production

- Neutral or client-branded packaging and documentation for direct shipment to distributors or retailers

For overseas brands, this OEM orientation is valuable because it allows them to expand or refresh product lines with minimal internal investment in machinery or labor.

Quality Assurance and Certifications

Quality control is a central concern when choosing die cut stickers manufacturers and suppliers, and many Indonesian producers address this through robust internal procedures and external certifications. While specific certifications vary by company, common elements include:

- Documented QC procedures from pre-press to final inspection

- Standardized color management to ensure consistent Pantone or CMYK reproduction across reorders

- Adhesion and durability tests for different substrates and environmental conditions

- Batch traceability and documentation that support audits and regulatory inspections

Many manufacturers also comply with international standards related to safety and environmental management and are familiar with documentation required for export to North America, Europe, and other regions. This gives overseas customers greater confidence in regulatory compliance and product reliability.

Typical Applications for Indonesian Die Cut Stickers

Because they combine flexibility, visual appeal, and relatively low cost, stickers from Indonesian die cut stickers manufacturers and suppliers are used in a wide range of applications:

Brand and Product Labels

Retail and e‑commerce brands use die cut stickers to label bottles, jars, boxes, pouches, and blister packs. Custom shapes and finishes help products stand out on shelves and online.

Promotional and Event Stickers

Marketing agencies and brand owners order die cut stickers as giveaways for trade shows, festivals, campaigns, and influencer kits. Creative shapes and coatings help reinforce brand identity and encourage sharing.

Industrial and Logistics Stickers

Die cut stickers serve practical purposes such as barcodes, QR codes, tracking labels, and warning signs on machinery or packaging. Durable materials and strong adhesives are critical in these contexts.

Apparel and Fashion Accessories

Many fashion brands rely on die cut stickers for size labels, temporary branding on packaging, and promotional stickers included in product boxes. This helps create a richer unboxing experience.

Security and Anti‑Counterfeit Uses

Certain die cut stickers manufacturers and suppliers also implement security features like tamper-evident cuts, destructible materials, microtext, or special inks. These are especially useful for high-value goods, electronics, and pharmaceuticals.

Trends Shaping the Indonesian Die Cut Sticker Market

Several global and regional trends are influencing how Indonesian die cut stickers manufacturers and suppliers operate and invest:

- Sustainability: Increased demand for recyclable or biodegradable materials, as well as reduced solvent-based inks

- Short-run and on-demand printing: Growth in digital printing supports smaller quantities and frequent design changes

- Personalization: More brands want limited editions or region-specific designs without large inventory commitments

- Integration with digital tools: Use of QR codes, NFC tags, and variable data printing to link physical stickers with online content or tracking systems

- Higher automation: Investment in automated die cutting, inspection, and packaging equipment to improve consistency and reduce lead times

For buyers, these trends translate into more options, faster response times, and increasing alignment with environmental and digital strategies.

How Overseas Buyers Can Work with Indonesian Suppliers

To make the most of working with Indonesia-based die cut stickers manufacturers and suppliers, overseas buyers should follow a structured approach that reduces risk and improves communication.

Clarify Specifications

Before contacting suppliers, define key specifications such as:

- Size and shape (including tolerance)

- Material type and thickness

- Adhesive strength and removal requirements

- Print colors (Pantone or CMYK references)

- Finishing (lamination, varnish, special effects)

- Application method (hand, semi-automatic, fully automatic)

Clear specifications help suppliers estimate cost and feasibility more accurately from the start.

Request Samples and Prototypes

Physical samples are essential to evaluating print quality, color accuracy, and adhesive performance. Many die cut stickers manufacturers and suppliers offer free or low-cost sample packs that showcase their materials and finishing options. For new projects, buyers can request pre-production samples or digital proofs for final confirmation.

Evaluate Communication and Service

Good communication is as important as technical capability. Buyers should assess:

- Response time to inquiries

- Level of detail in quotations

- Ability to understand and follow artwork and color instructions

- Openness to answering questions about materials, lead times, and logistics

Reliable partners usually provide transparent information and offer suggestions that improve both performance and cost-efficiency.

Consider Logistics and Lead Times

When working with overseas die cut stickers manufacturers and suppliers, consider the total lead time, including production, packing, shipping, and customs clearance. It is often wise to:

- Build extra time into the schedule for first orders

- Plan reorder cycles based on real consumption and transit times

- Discuss Incoterms, freight options, and documentation requirements in advance

This helps avoid stockouts and rush shipments, which can increase costs.

Comparing Key Factors When Selecting a Supplier

When evaluating Indonesian die cut stickers manufacturers and suppliers, consider the following core factors:

- Product range: Variety of materials, formats, and finishing options

- Technical capability: Ability to handle complex designs, tight tolerances, and special applications

- Quality consistency: Stability from batch to batch and across large orders

- Pricing and payment terms: Balance between cost, flexibility, and risk management

- Scalability: Capacity to grow with your business as order volumes increase

- Sustainability options: Availability of eco-friendly materials and processes

- Experience with export markets: Familiarity with your region's regulations and logistical challenges

A structured comparison based on these elements makes it easier to select the most suitable partner for long-term collaboration.

Positioning of OEM Providers from China

Many overseas buyers also work with Chinese OEM printing and packaging partners that supply die cut stickers globally. Companies such as Shenzhen-based manufacturers can complement Indonesian die cut stickers manufacturers and suppliers by offering:

- A broad portfolio of printed products beyond stickers, including display stands, cartons, plastic boxes, notebooks, flash cards, and promotional items

- Integrated OEM services that combine multiple printed components into complete packaging or marketing solutions

- Deep experience serving brand owners, wholesalers, and manufacturers in different regions

By working with both Indonesian and Chinese partners, brands can diversify their supply chains, balance cost and lead time, and enjoy a wide spectrum of technical and creative capabilities under one OEM ecosystem.

Conclusion

Indonesia has developed a strong and versatile ecosystem of die cut stickers manufacturers and suppliers, supported by solid printing know‑how, modern equipment, and increasing attention to sustainability. Buyers in sectors ranging from FMCG and e‑commerce to fashion and industry can find partners capable of delivering high-quality, custom-shaped stickers that enhance branding, improve functionality, and support global logistics.

By clearly defining requirements, evaluating supplier capabilities, and building long-term OEM relationships, businesses can leverage Indonesian die cut stickers manufacturers and suppliers as a strategic extension of their own production and marketing teams. Combined with complementary OEM partners in countries like China, this approach enables brands to build robust, flexible, and cost-effective sticker and packaging supply chains for worldwide markets.

FAQ

1. What are die cut stickers and how do they differ from regular labels?

Die cut stickers are stickers cut precisely to follow the shape of the design, rather than being limited to basic rectangles or circles. This results in a more visually appealing, custom look that helps products and branding stand out compared to standard, square-edged labels.

2. Why choose Indonesian die cut stickers manufacturers and suppliers for OEM projects?

Indonesian manufacturers combine competitive pricing with growing technical capability, making them attractive for long-term OEM partnerships. Many factories also offer flexible order quantities, modern printing technology, and experience with export procedures, which helps overseas buyers reduce risk and streamline sourcing.

3. What information should I provide when requesting a quote for die cut stickers?

You should specify size and shape, material type, adhesive requirements, print colors, finishing, quantity, and preferred packaging format (rolls, sheets, or singles). Providing artwork files and any color standards or samples you already use will help die cut stickers manufacturers and suppliers prepare accurate quotations and realistic lead time estimates.

4. Can Indonesian suppliers handle eco-friendly or sustainable sticker projects?

Yes, many Indonesian die cut stickers manufacturers and suppliers now offer eco-conscious options such as recycled paper stocks, biodegradable films, and low-VOC or water-based inks. Buyers should discuss environmental goals clearly so that the supplier can recommend suitable materials and processes that balance sustainability with performance.

5. How can I ensure consistent quality across repeat orders?

To secure consistency, work with your supplier to standardize materials, color profiles, and finishing specifications, and ask them to keep detailed production records and reference samples. Approving initial samples, giving clear feedback, and maintaining long-term cooperation with the same die cut stickers manufacturers and suppliers greatly improves the stability of quality for future reorders.