Content Menu

● Introduction

● Market Landscape

● Core Capabilities of Poker Cards Manufacturers and Suppliers

>> OEM and ODM Proficiency

>> Material and Finish Options

>> Printing and Color Management

>> Packaging and Ancillaries

>> Quality Assurance and Compliance

● Selecting a Poker Cards Manufacturer and Supplier

>> Alignment with OEM/ODM Needs

>> Material and Process Transparency

>> Lead Times and Logistics

>> Quality Control and Reputation

>> Sustainability and Responsibility

● Production Workflow: A Typical OEM/OEDM Pathway

● Use Case Scenarios

● Design and Creative Considerations

● Sustainability in Practice

● Market Trends and Innovation

● Conclusion

● FAQs

>> 1) What materials do poker cards manufacturers and suppliers commonly use?

>> 2) Can these suppliers handle large-scale OEM/ODM orders?

>> 3) What other products can be customized besides standard playing cards?

>> 4) How long does it take to receive a custom order?

>> 5) What factors influence cost and lead time?

● Citations

Introduction

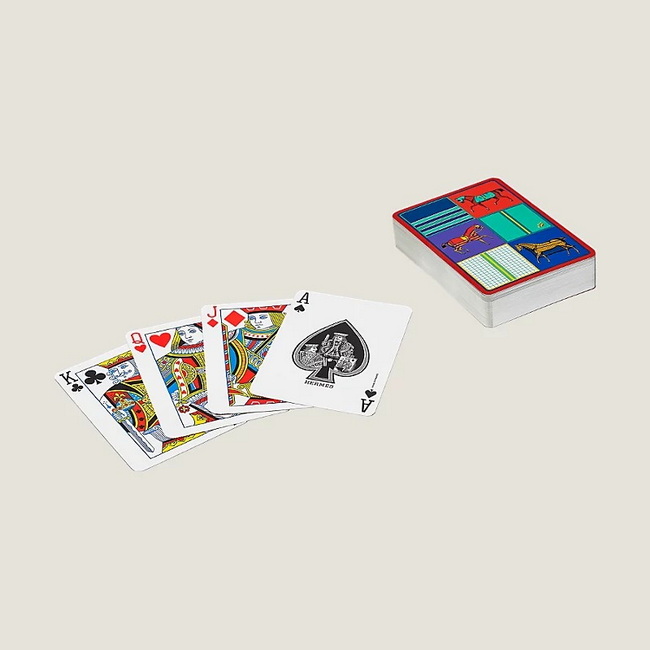

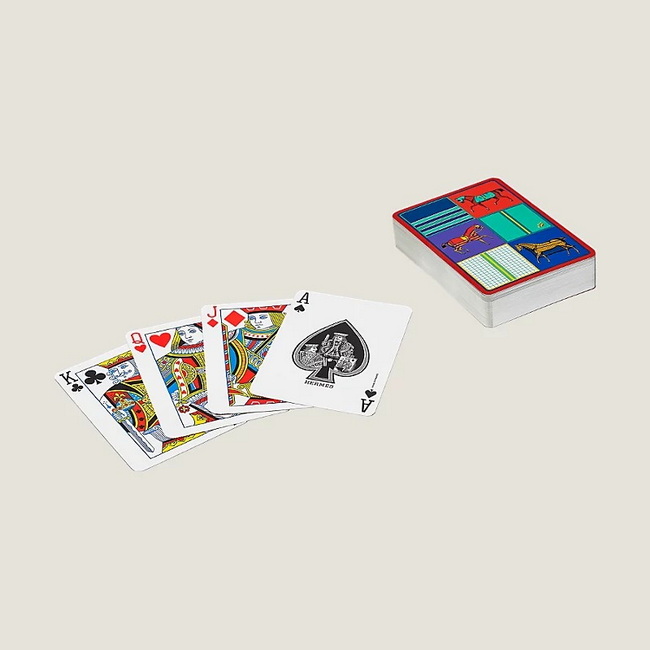

In today's competitive packaging and promotional materials landscape, custom playing cards and related products are a versatile vehicle for brand storytelling. For overseas brands, distributors, and manufacturers seeking OEM solutions, the market for poker cards and related items is expanding, driven by demand for high-quality, durable decks and compelling packaging. Shenzhen XingKun Packing Products Co., Ltd. stands at the intersection of traditional card-making craftsmanship and modern production technology, offering a broad suite of capabilities—from origination and design to finished decks with premium packaging. This article provides a comprehensive overview of poker cards manufacturers and suppliers in the broader region, with an emphasis on how to collaborate effectively with a partner who can deliver OEM services, ensure quality, and meet sustainability targets. The discussion covers material options, printing and finishing techniques, packaging integration, and strategic considerations for choosing the right supplier. Throughout, the emphasis remains on how this sector serves foreign brands, distributors, and manufacturers seeking reliable, scalable solutions for custom decks, educational cards, promotional sets, and related print products.

Market Landscape

The market for poker cards and related products combines timeless manufacturing know-how with modern manufacturing processes. Key dynamics shaping the landscape include:

- Customization demand: Clients increasingly seek decks that reflect brand identity, including bespoke back designs, face artwork, suit motifs, and serial numbering for limited editions.

- Material versatility: Suppliers offer a spectrum from traditional paper-based stock to coated or plastic cards, enabling durability for gaming, promotion, or educational use.

- Integrated packaging: High-impact packaging—custom tuck boxes, sliding cases, and multi-item sets—enhances shelf appeal and unboxing experiences.

- Brand safety and sustainability: Buyers favor suppliers with transparent material sourcing, eco-friendly coatings, and documentation that supports responsible procurement.

- Turnaround flexibility: Short-run promotions require rapid proofs and fast production cycles, while large campaigns benefit from scalable, repeatable processes.

Core Capabilities of Poker Cards Manufacturers and Suppliers

OEM and ODM Proficiency

- End-to-end design support: From concept to print-ready files, many suppliers offer in-house design teams or collaborate closely with client designers to realize brand visions.

- Proofing and iteration: Physical or digital proofs are standard, with rapid iteration cycles to meet tight launch deadlines.

- Large-scale and small-batch flexibility: Capabilities typically range from limited promotional runs to ongoing OEM programs with consistent supply.

Material and Finish Options

- Paper stock varieties: Premium coated, uncoated, and specialty stocks (linen, smooth, or matte textures) to achieve desired tactile feel.

- Coatings and finishes: UV gloss, matte, soft-touch, or embossed textures that enhance aesthetics and durability.

- Plastic and composite cards: PVC or PET-based decks for water resistance and longevity in high-use settings, with options for environmentally friendlier coatings.

Printing and Color Management

- High-resolution color reproduction: Accurate color matching across fronts and backs to maintain brand fidelity.

- Register precision: Multi-color printing with tight alignment ensures that suit symbols, numbers, and artwork align perfectly.

- Specialty effects: Foil accents, spot gloss, or tactile elements to elevate premium decks or limited editions.

Packaging and Ancillaries

- Custom storage and presentation: Branded tuck boxes, magnetic cases, or clamshell designs to protect and showcase decks.

- In-pack inserts: Quick-start guides, promotional cards, stickers, labels, or mini booklets that complement the decks.

- Labeling and compliance: Accurate labeling for safety, licensing, and country-specific regulatory requirements.

Quality Assurance and Compliance

- In-process inspections: Color checks, dimensional accuracy, and edge quality during production.

- Final QC: Deck completeness checks (e.g., 52-card sets plus jokers where applicable) and packaging integrity tests.

- Certifications and standards: Documentation and certifications relevant to regional markets, sustainability programs, and safety requirements.

Selecting a Poker Cards Manufacturer and Supplier

To achieve reliable results, buyers should evaluate potential partners against several criteria:

Alignment with OEM/ODM Needs

- Assess whether the supplier can accommodate your customization depth, from design collaboration through to finished packaging.

- Review proofing processes, sample availability, and the ability to scale production for future campaigns.

Material and Process Transparency

- Inquire about stock options, coatings, and recycled content, plus any limitations on customization.

- Request information on color management practices, proofing tolerances, and material safety data sheets.

Lead Times and Logistics

- Clarify estimated timelines for design, proofing, sampling, production, and shipping.

- Confirm acceptable rush options, minimum order quantities, and logistics arrangements (FOB, DDP, incoterms).

Quality Control and Reputation

- Seek references and case studies related to previous OEM projects, with metrics such as defect rates and on-time delivery.

- Verify quality-control methodologies, testing standards, and post-sale support.

Sustainability and Responsibility

- Ask about recycled materials, coatings with low environmental impact, and waste reduction practices.

- Look for transparent supply-chain information and any third-party sustainability certifications.

Production Workflow: A Typical OEM/OEDM Pathway

- Discovery and brief: Define decks, themes, quantities, packaging, and any accompanying materials.

- Design and proofs: Develop artwork, run proofs, and iterate until brand guidelines are met.

- Pre-press preparation: Create printing plates or digital files, set color profiles, and finalize die lines or laser-cut templates if used.

- Printing and coating: Execute face and back printing, apply coatings, and perform any foil or embossing steps.

- Die cutting and finishing: Cut cards to spec, round corners, and apply final finishes such as lamination or varnish.

- Assembly and packaging: Build decks into boxes, insert instructional or promotional materials, and finalize packaging.

- Quality control and shipment: Conduct final checks, pack securely, and arrange shipment with tracking and documentation.

Use Case Scenarios

- Brand promotions: Limited-edition decks that reflect corporate identity, paired with custom packaging and inserts for events or campaigns.

- Educational programs: Flash cards and teaching decks designed to support learning objectives, with branding or QR-driven content.

- Trade show giveaways: High-volume packs with consistent branding, designed for reliable on-site distribution and post-event engagement.

Design and Creative Considerations

- Branding consistency: Ensure brand colors, typography, and logos translate well onto card surfaces and packaging.

- Artwork production: High-resolution imagery, vector elements for scalability, and consideration for legibility of numbers and suits on small cards.

- Accessibility and inclusivity: Design choices that maintain readability for diverse audiences, including color-blind considerations where appropriate.

- Packaging storytelling: Align outer packaging with inner deck design to deliver a cohesive unboxing experience.

Sustainability in Practice

- Material choices: Preference for recycled fiber stock, responsibly sourced coatings, and recyclable packaging where feasible.

- Waste reduction: Efficient cutting plans and optimization of sheet usage to minimize scrap.

- Lifecycle considerations: Take-back or recycling options for plastic components and guidance on end-of-life disposal.

Market Trends and Innovation

- Digital integration: NFC tags or QR codes linked to digital content for enhanced consumer engagement and data capture.

- Personalization at scale: On-demand printing for limited runs, regional variants, or customized branding opportunities.

- Green manufacturing: Ongoing improvements in reducing water usage, energy intensity, and chemical footprint.

Conclusion

The landscape for Poker Cards Manufacturers and Suppliers combines traditional print craftsmanship with contemporary manufacturing techniques, offering a broad spectrum of options for decks, educational cards, and promotional sets. An effective OEM partner provides design support, material versatility, robust quality control, and a sustainable, scalable production pathway. By evaluating candidates against OEM/ODM capabilities, material choices, packaging integration, lead times, and sustainability commitments, brands can secure decks and related products that align with strategic goals and market needs. The right partnership not only yields high-quality decks but also reinforces brand storytelling through cohesive packaging, compelling artwork, and thoughtful ancillary materials.

FAQs

1) What materials do poker cards manufacturers and suppliers commonly use?

- A range of options includes premium coated paper stock for traditional decks and plastic-based materials like PVC or PET for durability, with coatings such as UV, matte, or soft-touch finishes to enhance feel and wear resistance.[1][2]

2) Can these suppliers handle large-scale OEM/ODM orders?

- Yes. Reputable Poker Cards Manufacturers and Suppliers in the region typically support scalable production, offering design collaboration, proofing, and efficient mass production with consistent quality control.[4][5]

3) What other products can be customized besides standard playing cards?

- Customization often extends to packaging boxes, inserts, stickers, labels, notepads, and promotional collateral that accompany decks, as well as educational flash cards and related game components.[7][11]

4) How long does it take to receive a custom order?

- Timelines vary by complexity and order size but typically range from a few weeks for simpler projects to several weeks for full packaging systems and large OEM runs, with expedited options available at premium costs.[3][12]

5) What factors influence cost and lead time?

- Key factors include deck size, customization depth, material choice, finishing options, packaging complexity, order quantity, and shipping terms. Transparent quotes should detail unit pricing, setup costs, and any rush fees.[6][8]

Citations

[1](https://www.youtube.com/watch?v=xr-8eFFJEas)

[2](https://www.suntree.asia/playing-cards-manufacturing-process/)

[3](https://www.industryprocess.com/blog/playing-cards.html)

[4](https://www.made-in-china.com/products-search/hot-china-products/Poker_Card.html)

[5](https://www.youtube.com/watch?v=XaXN_bfzk00)

[6](https://www.xkdisplay.com/top-playing-cards-manufacturers-and-suppliers-in-saudi-arabia.html)

[7](https://www.playingcard-factory.com/news/industry-news/the-production-process-of-playing-cards.html)

[8](https://www.accio.com/t-v2/plp/playing-card-manufacturing-machine)

[9](https://wishmanhelen.en.made-in-china.com/product/xjTQYItJjnhK/China-Manufacturer-Custom-Family-Paper-Printed-Card-Game-with-OEM-Design-for-Saudi-Arabic.html)

[10](https://www.chandni-industries.com/news/playing-card-manufacturing-guide)

[11](https://www.accio.com/plp/emirates-playing-cards)

[12](http://www.shippingonline.cn/Yellowpages/temp1/index.asp?solid=fdehdhi)