Content Menu

● Introduction

● 1: Market Overview and OEM Opportunities

● 2: Core Capabilities to Look For

● 3: Materials and Finishes in Card Production

● 4: Packaging and Display Solutions for Market Readiness

● 5: Quality Assurance and Production Efficiency

● 6: Case Studies and Real-World Applications

● 7: The Shenzhen XingKun Advantage in the UK Market

● 8: Practical Guidelines for Working with a Poker Cards Manufacturer

● 9: Future Trends in Poker Card Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. How do I choose a Poker Cards Manufacturer in the UK?

>> 2. What finishes are most durable for casino-grade decks?

>> 3. Can you provide sustainable packaging options?

>> 4. What is the typical lead time for a custom deck order?

>> 5. Do you offer licensing and art-services for branded decks?

● Citations

Introduction

The landscape of playing cards in the United Kingdom is a dynamic fusion of heritage craft and modern manufacturing technology. For brands seeking reliable OEM partners, the distinction between a good deck and a great deck often comes down to how a manufacturer handles design, materials, finishing, packaging, and logistics. This article examines the core considerations for poker cards manufacturers and suppliers operating in the UK market, with a focus on how Shenzhen XingKun Packing Products Co., Ltd.(as a global OEM partner) can deliver end-to-end solutions—from premium display stands and packaging boxes to customized poker cards and promotional materials. The goal is to help brands select partners that ensure consistent quality, scalable production, and compelling on-shelf presence across markets.

1: Market Overview and OEM Opportunities

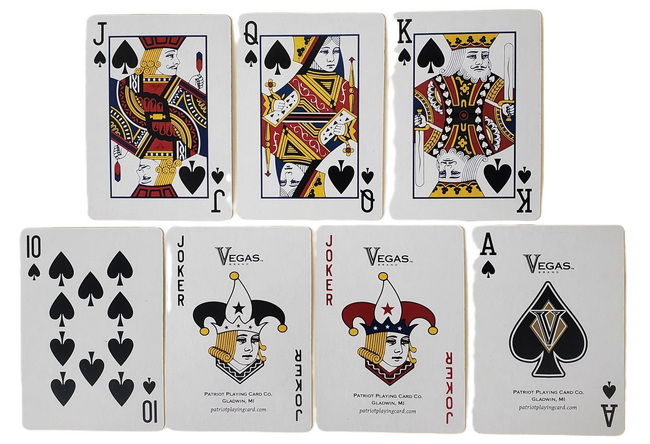

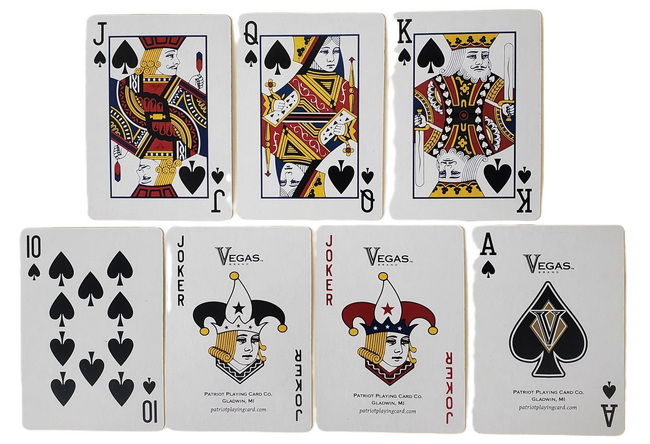

The UK market for playing cards encompasses casino operations, private gaming, educational and promotional decks, and niche collector sets. Demand drivers include durability for frequent handling, precise image reproduction for licensed designs, and packaging that protects decks during international shipping. For Poker Cards Manufacturers and Suppliers, success hinges on harmonizing paper or plastic stock, precise ink registration, durable coatings, and compliant, sustainable packaging. In today's competitive landscape, brands demand partners who can translate artwork into print-ready files, select appropriate card stock, and orchestrate complex packaging solutions for global distribution. Visual cues in production—from ungummed stock to finished decks—illustrate how an OEM collaboration yields consistent results across runs and time.[1][2]

2: Core Capabilities to Look For

- Design and prepress expertise

- Stock selection: paper versus plastic, core strength, and finish

- Color management and proofing workflows

- Finishes and embellishments: linen, smooth, lamination, UV coating, foil, embossing

- Cutting accuracy and corner rounding

- Quality assurance: bend tests, shuffle simulations, and color repeatability

- Packaging design and display solutions

- Licensing support and art services

- Sustainability certifications and compliance

A robust partner will offer transparent prototyping, sample testing, and clear lead-time estimates for both standard and custom decks. They will also provide options for eco-friendly materials (recycled paper, FSC-certified stock) and responsible packaging formats to meet evolving consumer and retailer expectations. Visual cues to illustrate capabilities should include process diagrams and sample swatches.[3][5]

3: Materials and Finishes in Card Production

- Card stock options: traditional paper-based stock with linen or smooth finishes versus plasticized or PVC-backed options for extended durability.

- Coatings: lamination, varnish, and overprint varnish to protect artwork and improve handling; matte versus gloss choices affect glare in store lighting and user perception.

- Core strength and thickness: commonly 270–310 gsm for standard decks, with stock choices influencing bend resistance and click feel.

- Corner treatment: round corners and re-edge finishing influence shuffling efficiency and user comfort.

- Printing techniques: offset printing for sharpness and color fidelity; occasional use of digital printing for short runs or licensing proofs.

- Special effects: foiling, embossing, spot UV, and foil stamping for licensed or premium decks.

- Sustainability: certification programs (FSC, ISO 9001) and recyclable packaging options.

These elements must align with quality control processes to ensure consistency across batches and orders. A strong supplier will provide sample swatches, performance data, and color proofs to minimize surprises during mass production.[4][7][8]

4: Packaging and Display Solutions for Market Readiness

Packaging is not merely a protective layer; it is a critical component of brand storytelling and in-store differentiation. Options typically include:

- Standard tuck boxes with printed designs

- Deluxe or premium packaging with foil accents, embossing, and specialty coatings

- Display-ready packaging and ship-ready boxes for efficient logistics

- Die-cut inserts and clear blister or windowed cartons for enhanced product visibility

- Display stands and counter-top fixtures tailored to deck dimensions

- Global carton specifications to meet varying regulatory and retail requirements

A well-orchestrated packaging strategy supports cross-border distribution, reduces damage in transit, and enhances consumer confidence at the point of sale. For OEMs, the ability to design packaging that aligns with licensing guidelines and regional preferences is a key differentiator.[11][12]

5: Quality Assurance and Production Efficiency

Quality assurance in poker card production encompasses several layered checks:

- Prepress verification: color accuracy, registration, and artwork integrity

- Material testing: durability, bend resistance, and surface uniformity

- In-process monitoring: machine calibration, alignment checks, and coating cure verification

- End-of-line testing: shuffle tests, bend tests, and random sampling for visual inspection

- Packaging QA: verification of deck count, order accuracy, and packaging integrity

Efficiency in production includes standardized work orders, clear bill-of-materials, and scalable capacity to accommodate promotions or limited-edition releases. Transparent lead times and a reliable logistics plan are essential for international customers, especially when dealing with complex licensing or custom artwork.[1][3]

6: Case Studies and Real-World Applications

Case studies illustrate how OEM partnerships translate into tangible results:

- Case A: A UK retailer seeks a proprietary deck for a limited-edition launch. A partner provides design adaptation, licensing coordination, and a premium linen-finish stock, achieving on-shelf impact and positive consumer feedback within a tight timeline.

- Case B: An international brand requires a high-volume run of licensed decks with standardized packaging for multiple markets. The manufacturer coordinates artwork proofs, ensures color consistency across runs, and delivers on-time shipments to 3 continents.

- Case C: A boutique brand wants eco-friendly packaging and recyclable tuck boxes. The supplier designs a sustainable solution using recycled stock and minimal plastic in the packaging, maintaining perceived premium quality.

These examples underscore the importance of end-to-end capabilities from design to delivery, reinforcing why Poker Cards Manufacturers and Suppliers should align with partners who can manage licensing, art direction, production, and logistics in a unified workflow.[6][9]

7: The Shenzhen XingKun Advantage in the UK Market

Shenzhen XingKun Packing Products Co., Ltd. brings a holistic OEM capability that spans display stands, packaging boxes, playing cards, notepads, flashcards, stickers, labels, and booklets. The company's strengths include:

- End-to-end OEM services: from initial artwork and proofs through printing, finishing, packaging, to final fulfillment

- Custom display solutions: tailored expo and in-store displays to maximize deck visibility

- Flexible packaging options: tuck boxes, premium packaging, and display-ready packaging

- Global compliance and quality systems: alignment with international standards to support cross-border distribution

- Enhanced collaboration: engineering support, project management, and rapid prototyping to expedite time-to-market

- A focus on educational and promotional products, enabling value-adds such as multi-item kits and bundled offers

By combining these capabilities with a strong emphasis on quality control, XingKun can serve UK and global brands seeking reliable OEM partnerships for Poker Cards Manufacturers and Suppliers.[13][14]

8: Practical Guidelines for Working with a Poker Cards Manufacturer

- Define clear objectives: deck count, finish, stock, packaging, licensing, and timelines

- Request samples early: verify color fidelity, stock performance, and finish durability

- Establish a color proofing workflow: CMYK vs. spot colors, color tolerance bands, and proof approval gates

- Confirm licensing and art services scope: rights management, artwork adaptation, and approvals

- Align packaging and display strategy with distribution plan: retailer requirements, shelf-fit, and logo guidelines

- Plan for sustainability: material choices, recyclability, and certifications

- Build a realistic timeline with buffer for approvals, proofing, and production delays

Effective collaboration hinges on transparent communication, detailed specifications, and a shared understanding of quality benchmarks.[5][3]

9: Future Trends in Poker Card Manufacturing

- Increased demand for licensed and branded decks with authentic artwork

- Greater emphasis on sustainability in materials and packaging

- Adoption of advanced coating technologies to enhance durability and shuffling feel

- Integration of anti-counterfeiting features in high-end decks

- Customization at scale, driven by digital proofing and on-demand production

- The growing importance of regional distribution hubs to shorten lead times

These trends shape how Poker Cards Manufacturers and Suppliers position themselves, particularly when serving cross-border brands and retailers.[9][10]

Conclusion

Choosing the right partner for Poker Cards Manufacturers and Suppliers means valuing a holistic capability set: design, materials, finishing, packaging, QA, and logistics. It also means recognizing the potential of a strategic OEM ally like Shenzhen XingKun Packing Products Co., Ltd. to deliver end-to-end solutions—from premium display stands to custom playing cards and related printed products. A well-integrated supplier reduces time to market, ensures consistent quality across runs, and enables brands in the UK and export markets to scale with confidence.

Frequently Asked Questions

1. How do I choose a Poker Cards Manufacturer in the UK?

Look for end-to-end capabilities (design, production, packaging, and logistics), strong QA processes, and proven licensing support. Verify color proofing, material certifications, and sample performance before committing.[3][1]

2. What finishes are most durable for casino-grade decks?

Casino-grade decks typically favor high-durability finishes such as high-quality lamination or varnish with a linen or smooth stock, designed for repeated shuffles and long-term handling. Color accuracy and edge wear resistance are key.[7][3]

3. Can you provide sustainable packaging options?

Yes. Sustainable options include recycled stock, FSC-certified materials, and minimal plastic packaging, with certifications that support retailer and consumer sustainability goals.[4][5]

4. What is the typical lead time for a custom deck order?

Lead times vary by order size, complexity (licensing, art services, finishes), and proofing cycles, but a well-organized OEM partner provides clear timelines from initial proofs to final delivery, with built-in buffers for approvals.[1][3]

5. Do you offer licensing and art-services for branded decks?

Many manufacturers provide licensing coordination and art services as part of the package, including artwork adaptation, color-proofing, and approvals, to ensure compliance and brand integrity across markets.[6][9]

Citations

[1](https://www.youtube.com/watch?v=xr-8eFFJEas)

[2](https://www.wopc.co.uk/playing-cards/manufacture)

[3](https://www.macaumr.com/custom-casino-playing-cards/)

[4](https://www.ivory.co.uk)

[5](https://www.wopc.co.uk/explore/keyword/manufacturing-processes/)

[6](https://www.ivory.co.uk/poker-playing-cards)

[7](https://aura-print.com/uk/custom-playing-card-printing)

[8](https://www.reddit.com/r/Damnthatsinteresting/comments/14sii1i/how_poker_cards_are_made/)

[9](https://www.youtube.com/watch?v=XaXN_bfzk00)

[10](https://pokersupplies.uk/knowledge-base/what-makes-bee-cards-casino-quality-for-home-games/)

[11](https://www.xkdisplay.com/zh-CN/)

[12](https://www.8mfg.com/casino-poker-chips-uk/)

[13](http://xingkun.yingfanzhileng.com)

[14](https://pokersupplies.uk/about/)