Content Menu

● Understanding the Basics of Sticker Making

● Essential Materials for Making Stickers

>> Sticker Paper

>> Adhesive Vinyl

>> Cutting Machine

>> Inkjet Printer

>> Laminating Sheets

>> Craft Knife

>> Design Software

>> Transfer Tape

>> Clear Sticker Paper

>> Additional Materials

● Types of Stickers You Can Create

>> Die-Cut Stickers

>> Kiss-Cut Stickers

>> Bumper Stickers

>> Window Decals

>> Custom Labels

● Tips for Making Your Own Stickers

● Conclusion

● Frequently Asked Questions and Answers

>> 1. What type of printer is best for making stickers?

>> 2. Can I make stickers without a cutting machine?

>> 3. How do I make my stickers waterproof?

>> 4. What is the difference between die-cut and kiss-cut stickers?

>> 5. How can I sell my homemade stickers?

Creating your own stickers can be a fun and rewarding project, whether you're looking to personalize your belongings, promote a business, or simply express your creativity. The process of making stickers can be as simple or as intricate as you want it to be, depending on the materials and tools you choose to use. In this article, we will explore the various materials you need to make your own stickers, the different types of stickers you can create, and some tips to help you get started.

Understanding the Basics of Sticker Making

Before diving into the materials, it's essential to understand the basic components of sticker making. Stickers are typically made from a combination of a design, a backing material, and an adhesive. The design can be anything from a simple graphic to a complex illustration, while the backing material provides structure and support. The adhesive is what allows the sticker to stick to surfaces.

Essential Materials for Making Stickers

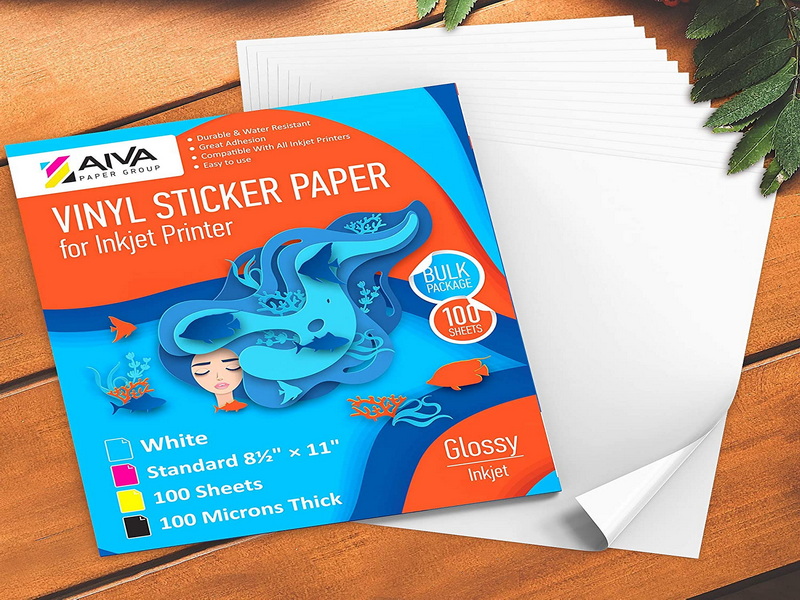

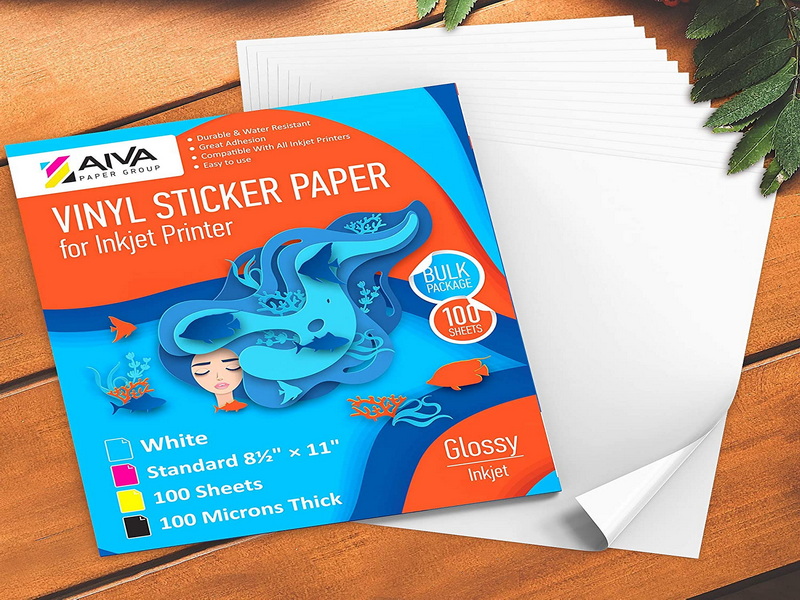

Sticker Paper

One of the most critical materials you will need is sticker paper. This paper is specially designed to be printed on and has an adhesive backing. There are various types of sticker paper available, including glossy, matte, and transparent options. Glossy sticker paper gives a shiny finish, making colors appear more vibrant, while matte paper offers a more subdued look. Transparent sticker paper is ideal for designs that you want to blend seamlessly with the surface they are applied to.

Adhesive Vinyl

If you want to create durable stickers that can withstand the elements, adhesive vinyl is an excellent choice. This material is often used for outdoor stickers because it is waterproof and UV resistant. Adhesive vinyl comes in various colors and finishes, including glossy and matte. It can be cut into intricate designs using a cutting machine, making it a popular choice for custom stickers.

Cutting Machine

A cutting machine, such as a Cricut or Silhouette, is a valuable tool for anyone serious about sticker making. These machines can cut precise shapes and designs from sticker paper or vinyl, allowing for intricate and professional-looking stickers. They often come with design software that makes it easy to create and customize your designs before cutting.

Inkjet Printer

An inkjet printer is essential for printing your designs onto sticker paper. When choosing a printer, ensure it can handle the type of sticker paper you plan to use. Some printers are better suited for glossy paper, while others work well with matte finishes. It's also important to use high-quality ink to ensure your designs are vibrant and long-lasting.

Laminating Sheets

If you want to add an extra layer of protection to your stickers, consider using laminating sheets. These sheets can be applied over your printed stickers to make them water-resistant and more durable. Laminating is especially useful for stickers that will be exposed to moisture or wear and tear, such as those used on water bottles or outdoor gear.

Craft Knife

A craft knife is a handy tool for cutting out stickers, especially if you are working with intricate designs that a cutting machine may not handle well. A craft knife allows for precision cutting and can be used to trim around the edges of your stickers for a clean finish. Make sure to use a cutting mat to protect your work surface.

Design Software

To create your sticker designs, you will need design software. There are many options available, ranging from free programs like Canva and GIMP to professional software like Adobe Illustrator. These programs allow you to create and manipulate graphics, add text, and prepare your designs for printing. Familiarizing yourself with design software can significantly enhance your sticker-making process.

Transfer Tape

If you are working with adhesive vinyl, transfer tape is an essential material. This tape allows you to transfer your cut designs from the backing paper to the desired surface without losing the shape or alignment. Transfer tape is especially useful for intricate designs with multiple pieces, ensuring that everything stays in place during application.

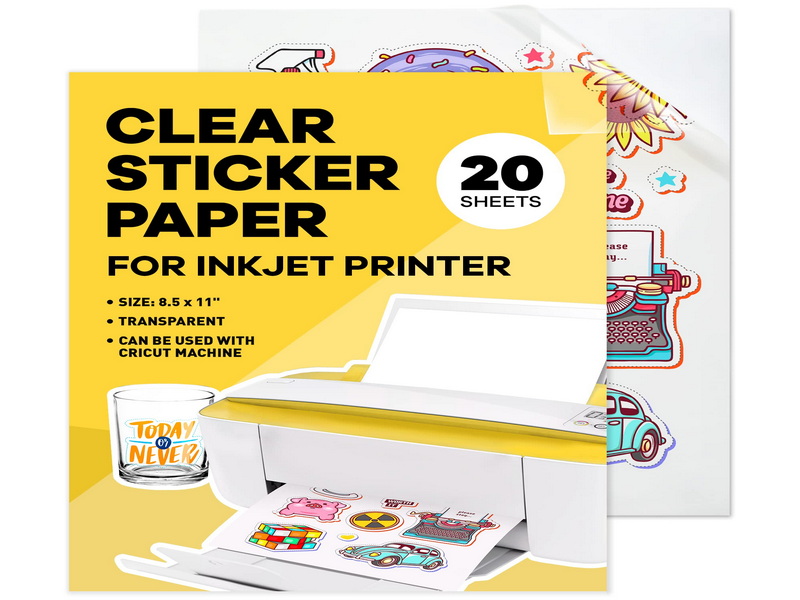

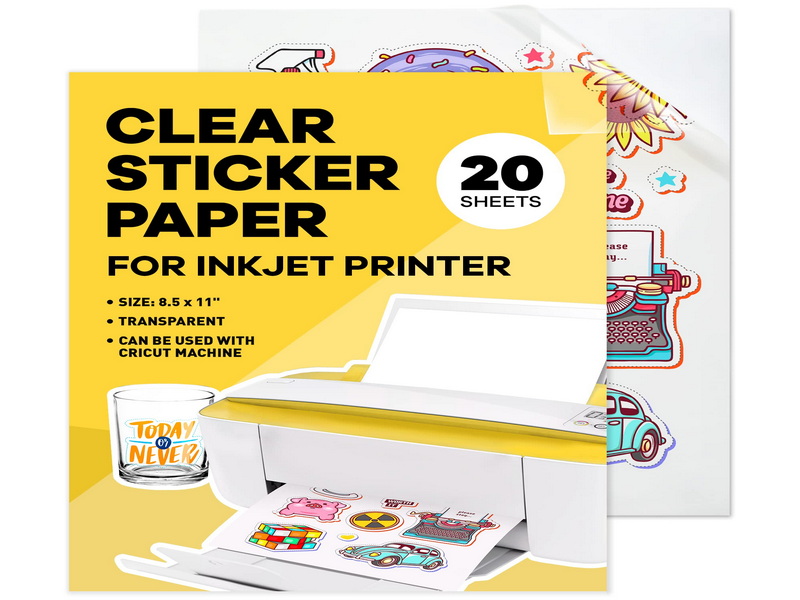

Clear Sticker Paper

For those who want to create stickers that have a transparent background, clear sticker paper is a must-have. This type of paper allows your designs to blend seamlessly with the surface they are applied to, making it ideal for window decals or stickers that you want to appear as if they are part of the surface. Clear sticker paper can also be printed on, allowing for full-color designs.

Additional Materials

Depending on your specific project, you may also want to consider additional materials such as markers, colored pencils, or stamps for adding unique touches to your stickers. These materials can help you personalize your stickers further and make them truly one-of-a-kind.

Types of Stickers You Can Create

Now that you know the essential materials, let's explore the different types of stickers you can create. The type of sticker you choose to make will often depend on the materials you have on hand and the purpose of the stickers.

Die-Cut Stickers

Die-cut stickers are cut to the shape of the design, meaning there is no excess material around the edges. These stickers can be made from both sticker paper and adhesive vinyl. They are popular for branding and promotional purposes, as they can feature logos or unique designs that stand out.

Kiss-Cut Stickers

Kiss-cut stickers are similar to die-cut stickers, but they are cut only through the top layer of the sticker paper, leaving the backing intact. This makes them easier to peel off and apply. Kiss-cut stickers are often used for sticker sheets, where multiple designs are printed on a single sheet.

Bumper Stickers

Bumper stickers are typically made from durable vinyl and are designed to withstand outdoor conditions. They are often used for advertising or expressing personal beliefs and can be printed in various sizes and shapes.

Window Decals

Window decals are made from clear adhesive vinyl and are designed to be applied to glass surfaces. These stickers can be used for business advertising or decorative purposes and can be printed in full color or as simple white designs.

Custom Labels

Custom labels can be created for various purposes, including product labeling, organization, and personal use. These stickers can be made from sticker paper or vinyl and can be printed with text and graphics to suit your needs.

Tips for Making Your Own Stickers

Creating your own stickers can be a fun and creative process. Here are some tips to help you get started:

1. Plan Your Design: Before you start printing or cutting, take the time to plan your design. Consider the size, colors, and overall look you want to achieve. Sketching out your ideas can help you visualize the final product.

2. Test Your Materials: If you're new to sticker making, it's a good idea to test your materials before committing to a large batch. Print a few test stickers to see how they look and hold up.

3. Use High-Quality Images: When creating your designs, use high-resolution images to ensure your stickers look professional. Low-quality images can appear pixelated when printed.

4. Experiment with Finishes: Don't be afraid to experiment with different finishes and materials. Try glossy, matte, or transparent sticker paper to see which works best for your designs.

5. Keep It Simple: If you're just starting, consider keeping your designs simple. Complex designs can be challenging to cut and apply, especially if you're using a craft knife.

6. Store Your Stickers Properly: Once you've made your stickers, store them in a cool, dry place to prevent damage. Keeping them in a protective sleeve or folder can help maintain their quality.

Conclusion

Making your own stickers is a creative and enjoyable activity that allows you to express your personality and ideas. By gathering the right materials, such as sticker paper, adhesive vinyl, and a cutting machine, you can create a wide variety of stickers for personal use or business purposes. Whether you're making simple designs or intricate custom stickers, the possibilities are endless. With a little practice and experimentation, you can develop your skills and create beautiful stickers that reflect your unique style.

Frequently Asked Questions and Answers

1. What type of printer is best for making stickers?

A high-quality inkjet printer is generally the best choice for making stickers, as it can produce vibrant colors and detailed images. Ensure that your printer can handle the type of sticker paper you plan to use.

2. Can I make stickers without a cutting machine?

Yes, you can make stickers without a cutting machine by using a craft knife to cut out your designs manually. This method may take more time and precision but is entirely feasible.

3. How do I make my stickers waterproof?

To make your stickers waterproof, you can use laminating sheets to cover them after printing. Alternatively, using adhesive vinyl can also provide a waterproof finish.

4. What is the difference between die-cut and kiss-cut stickers?

Die-cut stickers are cut to the exact shape of the design, while kiss-cut stickers are cut through the top layer only, leaving the backing intact. Kiss-cut stickers are easier to peel off and are often used on sticker sheets.

5. How can I sell my homemade stickers?

To sell your homemade stickers, consider setting up an online store on platforms like Etsy or Shopify. You can also promote your stickers on social media and at local craft fairs to reach a wider audience.