Content Menu

● Pizza Box Market Dynamics in Spain

● Leading Spanish Pizza Box Manufacturers and Suppliers

>> Smurfit Kappa Spain

>> Cartons Seville TeleCajas

>> LetsPACK

>> Portable Boxes Spain S.L.

>> Greif Packaging Spain SL

● Pizza Box Manufacturing Process in Spain

● Innovation and Sustainability

● Advantages of Working with Spanish Pizza Box Manufacturers and Suppliers

● Conclusion

● FAQ

>> 1. What materials are commonly used by pizza box manufacturers and suppliers in Spain?

>> 2. Can Spanish pizza box manufacturers provide customized packaging?

>> 3. How do pizza boxes keep pizzas fresh and hot during delivery?

>> 4. Are there eco-friendly pizza box options in Spain?

>> 5. What are typical minimum order quantities for OEM pizza boxes in Spain?

● Citations

Pizza box manufacturers and suppliers hold a pivotal role in the food packaging industry, particularly in Spain, where the fast-growing popularity of pizza has stimulated increasing demand for high-quality packaging solutions. With the rise of takeaway and delivery services, pizza boxes must not only protect and preserve the food but also provide branding opportunities and meet sustainability standards. This article delves into Spain's top pizza box manufacturers and suppliers, outlining their products, technologies, and innovations.

Pizza Box Market Dynamics in Spain

Spain's pizza box market is driven by factors such as the rising popularity of pizza consumption, the boom in home delivery and takeaway food services, and heightened consumer awareness of sustainability. Modern pizza box manufacturers provide a variety of packaging materials including corrugated cardboard, solid board, and clay-coated paperboard. Environmental concerns have pushed many suppliers towards eco-friendly and recyclable packaging options, reflecting government mandates promoting biodegradable materials and waste management policies.

The market also shows increasing demand for customized, branded pizza boxes that enhance brand visibility and customer engagement through print and design innovation. Food safety and hygiene considerations, amplified by recent global health concerns, further elevate the importance of reliable, single-use pizza packaging.

Leading Spanish Pizza Box Manufacturers and Suppliers

Smurfit Kappa Spain

A global leader in paper-based packaging, Smurfit Kappa operates manufacturing facilities in Spain that produce premium corrugated pizza boxes. Their offerings include a wide range of sizes and bespoke designs, allowing pizzerias and food brands to customize their packaging with logos, bespoke prints, and structural variations. Smurfit Kappa emphasizes sustainability, sourcing 100% biodegradable materials certified under Chain of Custody protocols. Their pizza boxes come flat-packed for logistical efficiency and quick assembly on site.

Cartons Seville TeleCajas

Based in southern Spain, Cartons Seville TeleCajas focuses on corrugated cardboard packaging, including pizza boxes made from fully recycled materials. This company aligns with the growing preference for sustainable packaging by offering eco-friendly options designed to protect pizzas during transit with minimal environmental impact. Their products cater to a variety of sectors, including foodservice, retail, and e-commerce.

LetsPACK

From Barcelona, LetsPACK provides a diverse portfolio of packaging products with a strong presence in the pizza box segment. Leveraging both traditional manufacturing and digital distribution channels, they accommodate bulk OEM orders and smaller runs with customizable options. LetsPACK's expertise extends to printing technologies that enhance pizza box aesthetics for greater consumer appeal.

Portable Boxes Spain S.L.

Specializing in custom-sized corrugated boxes, this Alicante-based company designs pizza boxes tailored for specific client requirements. They focus on precision die-cutting and printing solutions, enabling pizzerias and wholesalers to order pizza boxes with unique dimensions, functional features like ventilation, and printed branding. Their products adhere to food safety standards necessary for delivery and takeaway services.

Greif Packaging Spain SL

A subsidiary of the global packaging group Greif, Greif Packaging Spain manufactures pizza packaging solutions emphasizing durability and sustainability. Their boxes are optimized for logistics efficiency and brand differentiation, catering primarily to larger chains and professional food distributors. Their commitment to eco-conscious materials supports Spain's sustainable packaging goals.

Pizza Box Manufacturing Process in Spain

The production of pizza boxes in Spain involves sophisticated machinery and precise processes to ensure quality, functionality, and customization. The key steps include:

- Material Preparation: Corrugated sheets or solid board are sourced, often from recycled or FSC-certified paper fibers. Maintaining the board thickness and strength is essential to produce sturdy boxes.

- Printing: Design and branding are applied using rotary or flexographic printing, with options for up to several colors. Ink choice often prioritizes eco-friendliness.

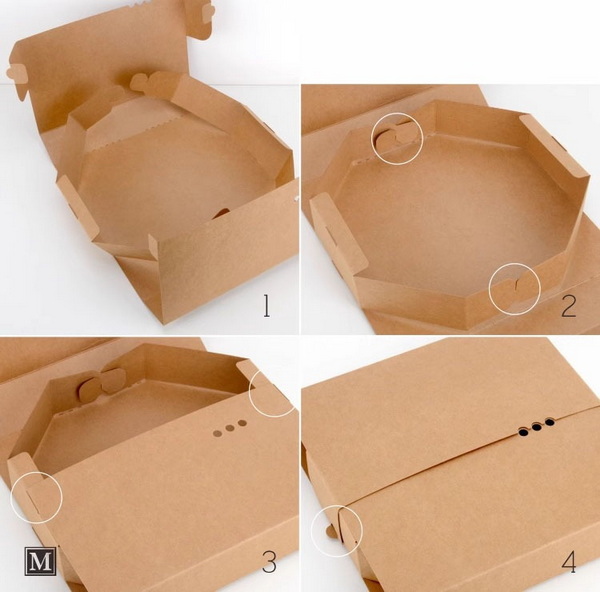

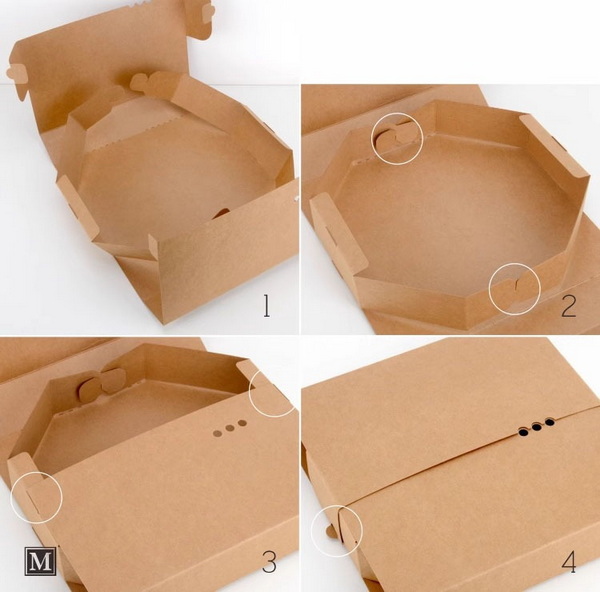

- Cutting and Creasing: Rotary die cutters or flexo folder gluers cut the sheets into precise box shapes and score lines to allow easy folding.

- Folding and Gluing: Boxes are automatically folded and glued into shape, with features such as ventilation holes for steam release.

- Quality Control and Packaging: Finished boxes are stacked and strapped for shipment, with quality checks in place to ensure accurate dimensions and print quality.

Automated machines, like those integrated into Spanish factories, allow short-run on-demand production of customized pizza boxes with quick changeovers, enabling responsiveness to varied client needs.

Innovation and Sustainability

Spanish manufacturers are at the forefront of integrating sustainability into pizza box production. They utilize recyclable kraft paper, avoid harmful inks, and develop compostable pizza boxes. Some companies offer advanced packaging solutions such as multi-pizza boxes with compartments for sides, interactive designs, and eco-friendly construction without sacrificing structural integrity.

The trend is toward circular economy packaging solutions that reduce waste through recyclability and biodegradability, meeting both regulatory requirements and evolving consumer expectations.

Advantages of Working with Spanish Pizza Box Manufacturers and Suppliers

- High-quality materials that preserve pizza freshness and temperature

- Flexible customization options for branding and box design

- Compliance with stringent food safety and environmental regulations

- Local manufacturing hubs ensuring efficient delivery and lower logistics costs

- Expertise in innovative printing and box design techniques

- Emphasis on sustainability and eco-friendly packaging formats

These benefits help foreign brands, wholesalers, and producers to source reliable OEM pizza box solutions tailored to the Spanish and international markets.

Conclusion

Spain's pizza box manufacturers and suppliers offer a compelling combination of quality, innovation, and environmental responsibility. Their expertise in delivering customized, sustainable, and visually appealing pizza packaging meets the growing demand generated by the dynamic foodservice sector. For businesses seeking OEM partners, Spain provides a diverse range of packaging suppliers who blend tradition with technology to support pizza branding and product protection. As market demands evolve, Spanish manufacturers continue to pioneer eco-conscious and functional pizza box solutions that benefit consumers, businesses, and the environment.

FAQ

1. What materials are commonly used by pizza box manufacturers and suppliers in Spain?

The primary materials include corrugated cardboard, solid board, and clay-coated cardboard. Most manufacturers use recyclable and biodegradable paper fibers, often certified by FSC or PEFC to ensure sustainable sourcing.

2. Can Spanish pizza box manufacturers provide customized packaging?

Yes, manufacturers offer complete customization of size, shape, and print design, including branding logos and marketing messages. Specialized shapes such as hexagonal or multi-compartment boxes are also available.

3. How do pizza boxes keep pizzas fresh and hot during delivery?

Pizza boxes are designed with ventilation holes to release steam and use insulating materials like corrugated cardboard to maintain heat and prevent sogginess, ensuring pizzas retain freshness.

4. Are there eco-friendly pizza box options in Spain?

Absolutely. Many pizza box manufacturers in Spain prioritize using recyclable, biodegradable materials and environmentally safe inks. This aligns with consumer demand and government regulations on waste reduction.

5. What are typical minimum order quantities for OEM pizza boxes in Spain?

Minimum order quantities vary by supplier but generally range from 1,000 to 25,000 pieces. This range accommodates small local pizzerias as well as large-scale distributors.

Citations

[1](https://www.youtube.com/watch?v=C5nNUPNvWAw)

[2](https://www.6wresearch.com/industry-report/spain-pizza-box-market)

[3](https://www.aopackmachine.com/how-to-make-custom-pizza-box/)

[4](https://www.aopackmachine.com/spanish-box-factory-modernized-production-with-bm3000-hd-all-in-one-box-maker-machine/)

[5](https://www.sciencedirect.com/science/article/abs/pii/S2214289420300508)

[6](https://fxsanmarti.com/fabrica-en.php)

[7](https://www.anchenggy.com/blog/custom-pizza-box-for-restaurant.html)

[8](https://www.smurfitwestrock.com/industries/foodservice/pizza-packaging)

[9](https://jetpaperbags.com/blogs/paper-bag-blogs/cost-factors-in-custom-pizza-box-production)