Content Menu

● Introduction

● Leading Pizza Box Manufacturers and Suppliers in the Netherlands

>> Arifal Cardboard Packaging

>> Smurfit Kappa Trobox

>> Europe Packaging

>> THIMM

>> Limepack

>> Paardekooper B.V.

● Manufacturing Process of Pizza Boxes in the Netherlands

● Product Features and Innovations

>> Sustainability and Environmental Responsibility

>> Customization and Branding Options

>> Food Safety and Durability

● Multimedia Content Recommendations

● Conclusion

● FAQ

>> 1. What materials are commonly used for pizza boxes in the Netherlands?

>> 2. Can I customize pizza boxes with my brand logo in the Netherlands?

>> 3. Are pizza boxes recyclable and environmentally friendly?

>> 4. How fast can pizza boxes be folded and assembled?

>> 5. What certifications should pizza box manufacturers have?

● Citations

Introduction

The Netherlands is home to some of the most innovative and reliable pizza box manufacturers and suppliers, offering high-quality, sustainable, and customizable packaging solutions. Catering primarily to foreign brands, wholesalers, and production companies, Dutch manufacturers provide pizza boxes that combine durability, food safety, and eco-friendliness with aesthetic appeal. This article delves deeply into the leading pizza box manufacturers and suppliers in the Netherlands, exploring their product offerings, manufacturing processes, custom branding options, and sustainability efforts. It is designed to inform international buyers seeking OEM services for pizza packaging.

Leading Pizza Box Manufacturers and Suppliers in the Netherlands

Arifal Cardboard Packaging

Arifal excels in corrugated cardboard packaging, including pizza boxes that offer strength and recyclability. Their packaging solutions balance lightweight designs with robust performance, making them ideal for food delivery applications. Arifal's commitment to sustainability resonates with environmentally conscious businesses aiming to reduce plastic use.[10]

Smurfit Kappa Trobox

Smurfit Kappa Trobox provides innovative paper-based packaging and stands out for its vertical integration owning paper mills that secure material quality. Their pizza boxes meet durability and food safety standards, featuring designs that improve heat retention and ventilation for optimal pizza freshness.[10]

Europe Packaging

Europe Packaging supplies a wide range of pizza boxes with various shapes and sizes customized to specific pizza dimensions. They emphasize custom packaging services to boost brand recognition and market competitiveness, aiding brands in standing out with eye-catching designs while protecting the product.[9][10]

THIMM

THIMM uses foodWave® corrugated cardboard with leak-proof coatings, positioning them as leaders in producing hygienic and sustainable pizza boxes. They ensure all materials comply with food-contact regulations and BRC standards. THIMM's dedication to sustainability is reflected through fully recyclable packaging tailored for direct food contact.[11]

Limepack

Limepack specializes in wholesale custom pizza boxes, offering nine sizes and two distinct shapes (classic square and hexagonal). Their full-color digital printing capabilities include vibrant logos and branding, producing glossy, premium pizza boxes. Limepack supports clients with free design drafts and expert consultancy for crafting premium pizzas' packaging.[12]

Paardekooper B.V.

Paardekooper provides corrugated Americano-style pizza boxes designed for temperature resistance and freshness preservation. Bulk orders with custom logo printings are available. Their environmentally friendly approach uses FSC-certified materials and plastic-free designs supporting sustainability and biodegradability goals.[13]

Manufacturing Process of Pizza Boxes in the Netherlands

Pizza box production in the Netherlands combines precision engineering with advanced materials science to achieve functional and attractive packaging. The process starts with selecting food-grade corrugated cardboard, typically made from a combination of virgin or recycled Kraft paper, chosen for its strength and environmental credentials.

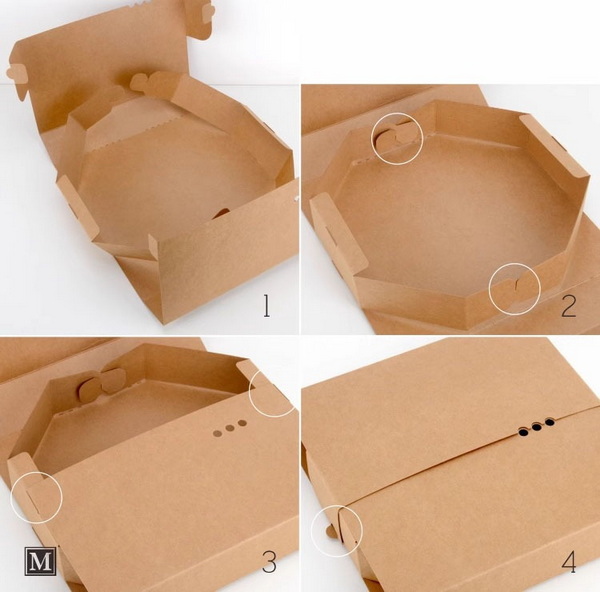

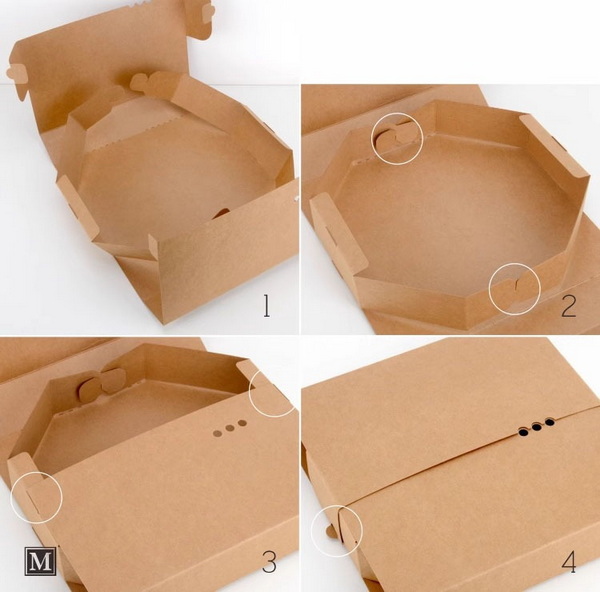

Blanks—the flat, cut cardboard sheets with scored fold lines—are produced by high-precision die-cutting machines. The scoring ensures easy folding while maintaining structural integrity. Production lines use adhesive applications such as corn starch glues, which are non-toxic and food-safe, to laminate layers of corrugated cardboard.

An important design feature includes upward-facing corrugated flutes on the box's bottom interior, which elevate the pizza above grease pools, maintaining crust crispness and preventing sogginess. Ventilation holes or cutouts control steam release, maintaining heat without condensation build-up, thus keeping pizzas fresh.

Digital printing on the flattened blanks enables vibrant, full-coverage branding. This customized printing is done with food-safe inks that comply with European food contact regulations. The finished blanks are folded and glued into boxes on automated lines, capable of producing thousands of boxes per hour with uniform quality.

The final packing stage ensures boxes are stacked and shipped safely to maintain shape and print integrity during transport and handling. Modern facilities also adhere to strict hygiene standards such as Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP), guaranteeing food safety at every stage.[1][2]

Product Features and Innovations

Sustainability and Environmental Responsibility

Most Dutch pizza box manufacturers prioritize environmental sustainability by using recyclable corrugated cardboard and avoiding plastic coatings. Innovative coatings like Comba® ensure grease resistance without compromising recyclability or compostability. Additionally, certifications like FSC, ISO 9001, and BRC validate adherence to sustainable sourcing and food safety standards. Companies also increasingly explore circular business models enabling reuse and material recovery in food packaging.[7][11][10]

Customization and Branding Options

Customization is central for many pizza box suppliers in the Netherlands. Digital printing techniques allow complex, multi-color designs without limitations, helping brands tell their stories and attract consumers visually. Box shapes vary beyond traditional squares, including hexagons and custom dimensions tailored to pizza sizes or promotional campaigns. Free consultation and design support services ensure packaging fits business needs. This flexibility helps boost brand differentiation in a competitive market space.[8][12]

Food Safety and Durability

Pizza boxes combine multiple corrugated cardboard layers for sturdiness and heat retention. Hygienic manufacturing processes with food-safe adhesives and inks ensure the box remains safe and odorless. Ventilation holes balance moisture control and heat retention, preserving pizza quality during transport. Thanks to fully recyclable materials, customers also enjoy environmentally conscious packaging without sacrificing functionality and food safety.[2][11]

Multimedia Content Recommendations

To engage readers, this article would benefit from:

- Detailed diagrams illustrating the corrugation design and vent hole placement that optimize pizza freshness.

- High-resolution product photos showing various printed pizza box designs from suppliers such as Limepack, Paardekooper, and THIMM.

- Videos demonstrating the rapid folding and assembly process of pizza boxes, highlighting manufacturing efficiency.

- Infographics summarizing the sustainability benefits, such as reduction in plastic waste and carbon footprint in pizza box production.

Conclusion

The Netherlands offers a robust market for pizza box manufacturers and suppliers known for delivering top-tier, sustainable, and fully customizable packaging solutions. Dutch suppliers combine innovative production technologies, food-safe materials, and strong ecological credentials to meet the needs of global brand owners and wholesalers seeking OEM services. Their focus on quality, environmental responsibility, and brand-enhancing designs makes them ideal partners in pizza packaging. Selecting a supplier from the Netherlands ensures access to expert craftsmanship, compliance with international standards, and creative packaging solutions aimed at maximizing product appeal and freshness.

FAQ

1. What materials are commonly used for pizza boxes in the Netherlands?

Pizza boxes are primarily made from food-grade corrugated cardboard, combining layers of virgin or recycled Kraft paper. They often feature grease-resistant coatings like Comba®, using eco-friendly, plastic-free materials approved for food contact.[11][10]

2. Can I customize pizza boxes with my brand logo in the Netherlands?

Yes, Dutch suppliers offer full-color digital printing that allows logos, graphics, and custom designs on pizza boxes. Custom sizes, shapes, and finishes are also available to meet specific branding and functional needs.[12][13]

3. Are pizza boxes recyclable and environmentally friendly?

Top pizza box manufacturers in the Netherlands produce fully recyclable boxes using sustainable fibers and eco-safe coatings, supporting circular economy goals. Certifications such as FSC and BRC affirm environmental and food safety compliance.[10][11]

4. How fast can pizza boxes be folded and assembled?

Modern manufacturing lines enable pizza boxes like the Americano model to be folded and ready for use in around seven seconds, offering high efficiency for pizza businesses and delivery services.[13]

5. What certifications should pizza box manufacturers have?

Look for certifications like BRC Global Standard for food safety, ISO 9001 for quality management, and FSC for sustainable sourcing to ensure packaging meets global standards for safety and sustainability.[11][10]

Citations

[1](https://patents.google.com/patent/US4441626A/en)

[2](https://jetpaperbags.com/blogs/paper-bag-blogs/compliance-safety-standards-pizza-box-manufacturing)

[3](https://lansbox.com/cost-to-manufacture-a-pizza-box/)

[4](https://www.youtube.com/watch?v=el5mpv_L9n4)

[5](https://pakoro.com/pizza-box-factory/)

[6](https://www.yoonpak.com/custom-pizza-box-making-guide/)

[7](https://www.sciencedirect.com/science/article/pii/S2352550924001350)

[8](https://cartoveneta.it/en/boxes-and-packaging/custom-pizza-cardboard/)

[9](https://europepackaging.com/en/pizza-boxes)

[10](https://www.corrugatedboxmanufacturer.com/corrugated-boxes-netherlands/)

[11](https://www.thimm.com/en/packaging/food-packaging/pizza-boxes/)

[12](https://www.limepack.eu/food-boxes/178-custom-pizza-boxes.html)

[13](https://www.paardekooper.nl/en_US/p/pizza-box-corrugated-cardboard-32x32x3cm-americano-white/1529/)