Content Menu

● Overview of Swedish Pizza Box Manufacturers and Suppliers

● Leading Pizza Box Manufacturers in Sweden

>> DS Smith Packaging Sweden AB

>> Kaizen Emballage AB

>> Stora Enso Packaging AB

>> Smurfit Kappa Pegewell AB

>> Nefab AB

● The Manufacturing Process of Pizza Boxes in Sweden

● Compliance and Safety Standards in Pizza Box Production

● Why OEM Services Matter

● Sustainability Initiatives in Swedish Pizza Box Manufacturing

● Choosing the Right Pizza Box Manufacturer in Sweden

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the common materials used for pizza boxes in Sweden?

>> 2. Can I get fully customized pizza boxes with branding in Sweden?

>> 3. How do Swedish manufacturers ensure pizza box food safety?

>> 4. What sustainability practices are common among Swedish pizza box suppliers?

>> 5. What is the typical lead time for pizza box production in Sweden?

● Citations

In the evolving food packaging industry, pizza boxes are essential for preserving the quality of the product and enhancing brand recognition. For businesses in Sweden's food sector, selecting trusted pizza box manufacturers and suppliers who provide superior, customizable, and sustainable packaging solutions is vital. This article delves into the top pizza box manufacturers and suppliers operating in Sweden, examines their product features, manufacturing processes, compliance standards, and sustainability practices, aiming to support brands in making informed decisions.

Overview of Swedish Pizza Box Manufacturers and Suppliers

Sweden is recognized globally for its commitment to innovation and environmental responsibility, traits that reflect strongly in its packaging industry. Several leading companies supply the food sector with high-quality pizza boxes designed specifically to preserve pizza freshness, withstand heat, and support brand marketing through custom designs.

Most manufacturers offer Original Equipment Manufacturer (OEM) services, producing boxes that serve the unique branding and operational needs of pizza restaurants, wholesalers, and international clients. Their production processes integrate advanced printing technology and eco-friendly materials, balancing aesthetics, functionality, and sustainability.

Leading Pizza Box Manufacturers in Sweden

DS Smith Packaging Sweden AB

DS Smith Packaging is a prominent manufacturer offering pizza boxes with an emphasis on sustainability and consumer safety. Their packaging solutions integrate multiple materials with a focus on industrial and retail needs. They specialize in custom sizes and high-quality printing, ensuring that pizzas are not only well-protected but also effectively showcased.

Their commitment to sustainable materials and processes aligns with the growing demands for eco-conscious products, making them a top choice for Swedish and international pizza brands.

Kaizen Emballage AB

Kaizen Emballage excels in producing corrugated cardboard packaging, including pizza boxes with customization options such as two-color inline printing. Their ability to manufacture shorter production runs and prototypes allows clients to approve designs before large-scale orders, adding flexibility.

The company also offers complementary packaging materials like kraft paper and polyethylene products to complement pizza box production, catering to a broad spectrum of packaging needs.

Stora Enso Packaging AB

Stora Enso is a leader in renewable packaging solutions, utilizing wood-based biomaterials to manufacture eco-friendly pizza boxes. They focus heavily on sustainability through responsible sourcing and innovation in biodegradable packaging, ensuring their offerings meet strict environmental standards.

Their boxes are designed not just for durability and food safety but also with a reduced carbon footprint, making them attractive to environmentally conscious consumers and brands.

Smurfit Kappa Pegewell AB

Smurfit Kappa provides pizza boxes made of corrugated board that handle high temperatures and insulate pizzas efficiently. Known for their integrated production and logistics expertise, they offer custom printing, embossing, and die-cut features, including ventilation holes and specialized holders for sauces.

Their extensive network and advanced manufacturing capabilities ensure reliable supply and consistent quality, suitable for large-scale operations.

Nefab AB

Nefab emphasizes packaging solutions that combine protection, sustainability, and versatility. Offering pizza boxes in popular sizes, they use corrugated board and foam cushioning materials, providing superior product protection without compromising environmental considerations.

Their packaging engineers and in-house test labs ensure compliance with rigorous quality and safety standards, making them a dependable supplier for pizza businesses.

The Manufacturing Process of Pizza Boxes in Sweden

Pizza box manufacturing in Sweden adheres to stringent compliance, quality, and sustainability standards. The process typically begins with selecting raw materials—mostly recycled or virgin corrugated cardboard certified by organizations like FSC to guarantee sustainable sourcing.

Key steps include:

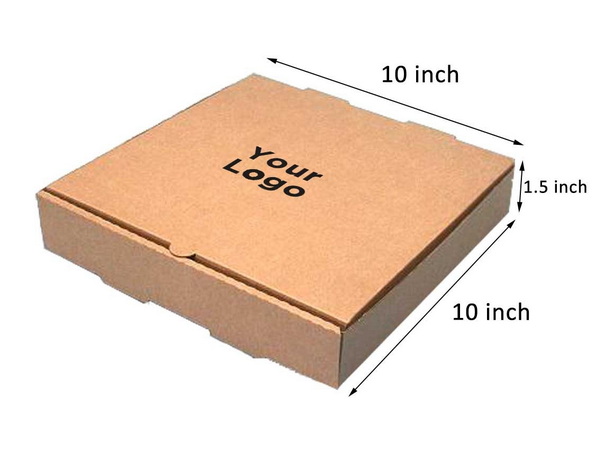

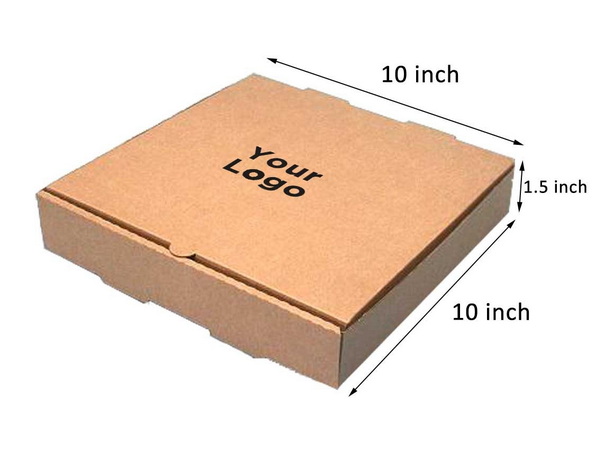

- Design and Customization: Boxes are designed with customer specifications, including size, printing, and special die cuts for ventilation or condiment holders.

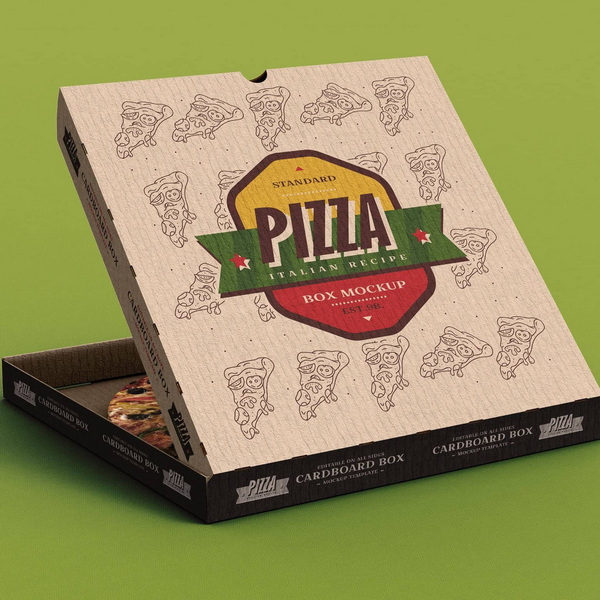

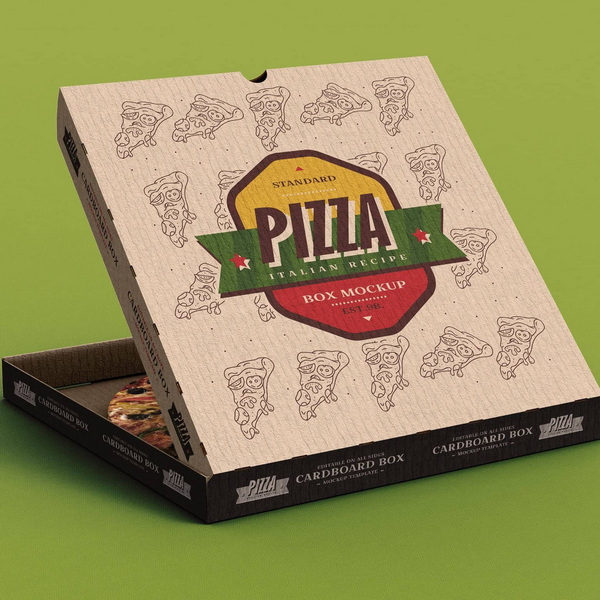

- Printing: Advanced printing technologies such as flexographic, offset, and digital inkjet printing are used to apply logos and marketing messages with high resolution and color fidelity.

- Cutting and Creasing: The cardboard is cut, creased, and folded using precision machinery to ensure ease of assembly and product protection.

- Quality Control: Rigorous quality checks ensure structural integrity, food safety compliance, and printing accuracy.

- Sustainability Integration: Many manufacturers focus on reducing material use by developing lighter boxes without compromising strength, such as Metsä Board's innovation of the world's lightest pizza box that reduces carbon footprint by 50%.

This environmentally conscious approach ensures pizza boxes are safe, functional, and fit modern demands for sustainability.

Compliance and Safety Standards in Pizza Box Production

Sweden's pizza box manufacturers strictly follow food safety and environmental regulations. These include the use of food-grade inks, adhesives, and coatings approved for direct food contact to avoid contamination. Common adherence to ISO certifications (ISO 22000 for food safety and ISO 9001 for quality management) underscores their commitment to high standards.

Manufacturing facilities implement Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) to minimize risks related to hygiene and operational errors. FSC certification regulates material sourcing, ensuring that paper and cardboard come from responsibly managed forests, further contributing to deforestation reduction.

Recyclability and biodegradability are prioritized to promote circular economy principles within packaging industries, which aligns with both consumer expectations and government legislation, including Sweden's packaging producer responsibility ordinance.

Why OEM Services Matter

OEM services allow pizza box suppliers to tailor products precisely for clients' branding and logistical preferences. Swedish manufacturers excel in providing OEM capabilities including:

- Customized box sizes tailored to specific pizza dimensions.

- High-quality full-color printing and embossing for brand visibility.

- Functional features such as ventilation holes, die cuts for sauces, and easy-open tabs.

- Environmentally friendly coatings and materials.

These services help pizza brands stand out in a competitive market, improve customer performance through better packaging, and uphold sustainability promises.

Sustainability Initiatives in Swedish Pizza Box Manufacturing

Sustainability is at the core of Swedish packaging innovation. Leading manufacturers incorporate renewable materials, reduce packaging weight, and eliminate plastic linings by introducing biodegradable coatings. For example, Metsä Board's lightweight pizza box uses uncoated white kraftliner that boosts recyclability and enhances consumer tactile experience.

Manufacturers invest in sustainable forest management and reduce carbon emissions throughout the supply chain. Their efforts encompass design innovations that optimize packaging material use, manufacturing efficiency, and end-of-life recyclability, making Swedish pizza boxes standout for both quality and ecological responsibility.

Choosing the Right Pizza Box Manufacturer in Sweden

Businesses seeking pizza box suppliers in Sweden should carefully evaluate:

- Material Quality and Certifications: Ensure packaging materials are food-safe, durable, and FSC certified.

- Customization Options: Check for print quality, size variations, and additional functional features.

- Sustainability Commitment: Favor suppliers with clear environmental policies and certifications.

- Production Capacity and Lead Times: Match supplier capabilities with business volume and delivery deadlines.

- Customer Service: Consider design support, sample provision, and logistics reliability.

A well-selected partner will enhance brand value, operational efficiency, and customer satisfaction through superior pizza box solutions.

Conclusion

Sweden's pizza box manufacturers and suppliers are recognized for their blend of innovation, high-quality materials, customization capabilities, and remarkable dedication to sustainable practices. Industry leaders like DS Smith Packaging, Stora Enso, Smurfit Kappa, and Kaizen Emballage blend environmental responsibility with advanced manufacturing and printing technologies to produce pizza boxes that protect, promote, and preserve.

Choosing the right Swedish manufacturer ensures a consistent supply of durable, safe, and eco-friendly pizza boxes that meet business and consumer expectations alike. This comprehensive guide offers valuable insights for pizzerias, wholesalers, and food brands aiming to elevate their packaging while embracing sustainability.

Frequently Asked Questions (FAQ)

1. What are the common materials used for pizza boxes in Sweden?

Most Swedish manufacturers use corrugated cardboard made from virgin or recycled wood fibers sourced sustainably. They apply food-grade inks and coatings that often are biodegradable or recyclable to maintain safety and environmental standards.

2. Can I get fully customized pizza boxes with branding in Sweden?

Yes, Swedish suppliers offer extensive customization, including box sizes, full-color high-resolution printing, embossing, and functional die cuts for ventilation or condiment holders.

3. How do Swedish manufacturers ensure pizza box food safety?

They comply with strict safety standards, including ISO 22000, use food-safe materials, and implement Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) protocols to prevent contamination during production.

4. What sustainability practices are common among Swedish pizza box suppliers?

Manufacturers employ renewable materials, reduce packaging weight, replace plastic coatings with biodegradable alternatives, and source FSC-certified paper, aiming for minimal environmental impact and high recyclability.

5. What is the typical lead time for pizza box production in Sweden?

Lead times vary but most suppliers provide quick sample turnaround and small batch production within weeks. Large orders follow based on agreed production schedules, with some flexibility for urgent demands.

Citations

[1](https://packagingeurope.com/news/worlds-lightest-pizza-box-produced-by-mets%C3%A4-board-and-industry-partners/9902.article)

[2](https://jetpaperbags.com/blogs/paper-bag-blogs/compliance-safety-standards-pizza-box-manufacturing)

[3](https://www.linkedin.com/pulse/sweden-paper-pizza-box-market-landscape-key-data-baqac)

[4](https://www.smurfitkappa.com/products-and-services/packaging/pizza-boxes)

[5](https://cartoveneta.it/en/boxes-and-packaging/custom-pizza-cardboard/)

[6](https://lup.lub.lu.se/student-papers/record/4611296/file/4611300.pdf)

[7](https://xmgmediaww.com.au/how-pizza-box-marketing-works/)

[8](https://www.smurfitwestrock.com/industries/foodservice/pizza-packaging)

[9](https://www.naturvardsverket.se/en/guidance/extended-producer-responsibility-epr/producer-responsibility-for-packaging/)