Content Menu

● Introduction

● Evolution of Uno Card Production in North America

● OEM Capabilities and ServiceStacks

>> Card design and artwork adaptation

>> Material selection and finishes

>> Packaging and display integration

>> Compliance, safety, and sustainability

● Product breadth and adjacent offerings

>> The core deck and variants

>> Educational, family, and novelty formats

>> Ancillary print products for a cohesive brand ecosystem

● Quality assurance and optimization

>> Prepress and color management

>> In-line inspection and post-press testing

>> Packaging integrity and shelf life

● Logistics, supply chain, and lead times

>> Domestic and cross-border considerations

>> Demand forecasting and agile manufacturing

● Choosing the right Uno Cards Manufacturers and Suppliers partner

>> Due diligence and supplier evaluation

>> Co-creation and project management

>> Commercial terms and risk management

● Case studies and brand stories

>> Co-branded conventions and promotional decks

>> Licensed-property collaborations

● Market trends and the future of Uno Cards manufacturing

>> Sustainability and circularity

>> Digital integration and smart packaging

● Safety, licensing, and ethics

>> Licensing structures and brand governance

● Conclusion

● FAQ

>> 1. What certifications should I look for in Uno cards manufacturers?

>> 2. What is a typical MOQ for custom UNO decks with OEM partners?

>> 3. How long does a typical sample-and-prototype phase take?

>> 4. Can packaging be co-designed with the card design for brand consistency?

>> 5. Do UNO-related decks require license management in the US market?

Introduction

Shenzhen XingKun Packing Products Co., Ltd. stands at the intersection of high-quality printing, innovative packaging, and turnkey OEM services. This article examines the landscape of Uno Cards Manufacturers and Suppliers operating in America and beyond, highlighting the capabilities that matter to brands seeking custom decks, co-branded packaging, and complete retail-ready solutions. It explores manufacturing strategies, quality-control paradigms, material choices, and the evolving demand for sustainable and compliant packaging.

Evolution of Uno Card Production in North America

The production of Uno Cards and related products has evolved from simple, single-source runs to sophisticated, global supply networks. Modern manufacturers combine advanced prepress workflows, high-speed printing, precision cutting, and automated quality inspection to deliver consistent color, finish, and deck integrity at scale. The Uno Cards Manufacturers and Suppliers ecosystem now often includes tiered service offerings—from basic private-label decks to fully integrated product suites that encompass artwork, packaging, display systems, and point-of-sale materials.

OEM Capabilities and ServiceStacks

Card design and artwork adaptation

- In a competitive market, card artwork must translate across different print processes, substrates, and finishes. OEM partners typically provide design support, color management, and artwork optimization to ensure faithful reproduction on a range of stock types. This includes compliance with branding guidelines, licensing constraints (where applicable), and proofing stages that minimize costly revisions.

Material selection and finishes

- Card stock options often span core, ivory, and speciality blends, with finishes such as linen, air-cushion, or matte coatings. Packaging finishes may include aqueous coatings, UV embossing, and foil accents. The choice of stock and finish directly influences durability, handling feel, and consumer perception on shelves.

Packaging and display integration

- Retail packaging design is integral to brand storytelling. OEMs frequently deliver tuck boxes, windowed packaging, and shelf-ready displays that align with card design, enabling a seamless consumer experience from unboxing to play.

Compliance, safety, and sustainability

- Compliance considerations include toy safety standards, labeling requirements, and material certifications (such as FSC for responsibly sourced packaging). Sustainability trends drive the use of recycled or responsible-origin materials, minimal plastic use, and clear recyclability messaging.

Product breadth and adjacent offerings

The core deck and variants

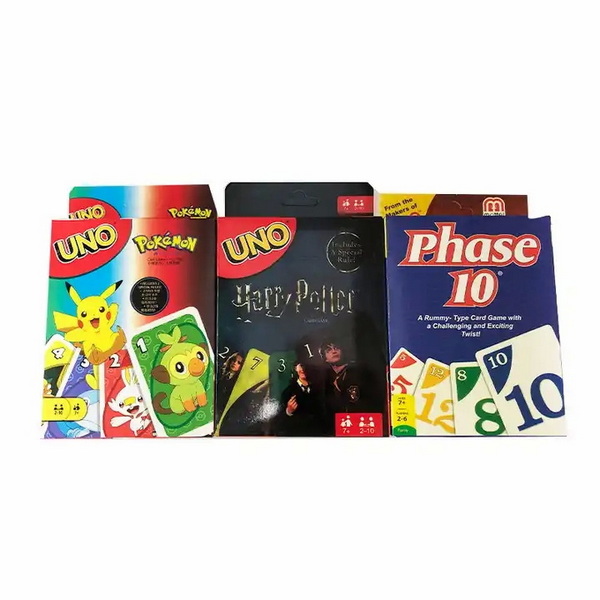

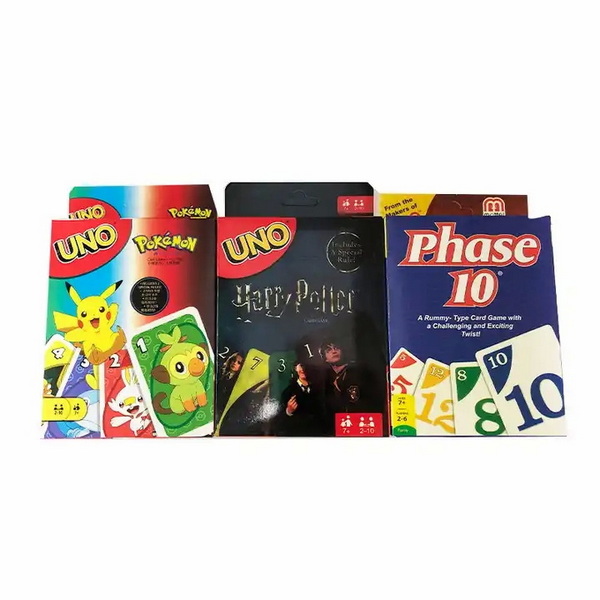

- Standard Uno-style decks remain the backbone of many manufacturing collaborations. Variants may include licensed themes, regional adaptations, or collector editions designed to ignite retailer interest and fan enthusiasm.

Educational, family, and novelty formats

- Beyond classic decks, manufacturers frequently offer flashcards, family-game bundles, and niche card formats that support marketing campaigns or educational initiatives.

Ancillary print products for a cohesive brand ecosystem

- A single supplier often coordinates related packaging artifacts such as stickers, labels, booklets, and instruction inserts, ensuring consistent color management and brand voice across all touchpoints.

Quality assurance and optimization

Prepress and color management

- Tight color management standards are essential to ensure that the final product matches the approved proofs across batches. Digital color profiling, standardized ICC profiles, and cross-material calibration support consistent results from run to run.

In-line inspection and post-press testing

- Modern lines incorporate automated inspection for misprints, mis-cuts, and coating defects. Random sampling and batch traceability enable rapid containment of quality issues and traceable reproduction of results.

Packaging integrity and shelf life

- Integrity testing covers shrink-wrap stability, glue adhesion for tuck boxes, and label adhesion under varying temperature and humidity conditions, ensuring packaging remains pristine through distribution.

Logistics, supply chain, and lead times

Domestic and cross-border considerations

- Proximity to customers reduces lead times and lowers logistics risk. Manufacturers often maintain regional warehouses, or collaborate with 3PL partners to balance speed and cost.

Demand forecasting and agile manufacturing

- Flexible manufacturing capabilities, short-run options, and scalable production enable brands to respond to market fluctuations, promotions, or limited-edition launches without sacrificing quality.

Choosing the right Uno Cards Manufacturers and Suppliers partner

Due diligence and supplier evaluation

- Key criteria include track record, facility audits, quality systems, and customer references. Request production samples, test reports, and a clear QMS statement to understand how quality is built into every deck.

Co-creation and project management

- Strong collaboration frameworks help ensure that creative concepts align with production feasibility, timelines, and budget. Dedicated project managers and transparent communication are essential to success.

Commercial terms and risk management

- Clear MOQs, price tiers, freight terms, and warranty provisions reduce surprises and protect brand investments.

Case studies and brand stories

Co-branded conventions and promotional decks

- Case studies illustrate how brands leverage Uno Cards Manufacturers and Suppliers to deliver decks aligned with marketing calendars, seasonal campaigns, and fan events.

Licensed-property collaborations

- Licensed partnerships require careful licensing compliance, asset management, and brand governance to ensure consistency with the license owner's standards.

Market trends and the future of Uno Cards manufacturing

Sustainability and circularity

- The industry is moving toward recycled materials, refillable packaging concepts, and clearer end-of-life messaging to satisfy environmentally conscious consumers.

Digital integration and smart packaging

- Increasing use of QR-enabled packaging, augmented product guides, and digital content links enhances the consumer experience and provides measurable engagement data.

Safety, licensing, and ethics

Licensing structures and brand governance

- Official UNO products operate under licensing frameworks; partnering with manufacturers requires adherence to brand guidelines and licensing terms to protect IP and consumer trust.

Conclusion

Uno Cards Manufacturers and Suppliers form the backbone of reliable, scalable, and creative card-product ecosystems. The most successful collaborations marry rigorous quality control, transparent communication, and the capacity to deliver design fidelity across materials and formats. For brands seeking a one-stop OEM partner, a cohesive strategy that aligns card design, packaging, and retail execution is essential to maximize shelf impact, consumer delight, and long-term loyalty.

FAQ

1. What certifications should I look for in Uno cards manufacturers?

- Concise answer: Look for ISO 9001 or equivalent quality-management certification, relevant toy-safety testing where required, and any packaging-related sustainability certifications such as FSC. This ensures robust quality systems and responsible sourcing.

2. What is a typical MOQ for custom UNO decks with OEM partners?

- Concise answer: MOQs commonly range from 1,000 to 5,000 units, though some manufacturers can accommodate smaller runs with higher per-unit costs, depending on stock availability and customization complexity.

3. How long does a typical sample-and-prototype phase take?

- Concise answer: Initial concept proofs usually take 1–2 weeks, with final print-ready prototypes typically 2–4 weeks, depending on artwork changes and approvals.

4. Can packaging be co-designed with the card design for brand consistency?

- Concise answer: Yes; many OEMs offer integrated design services to ensure color, finish, and branding alignment across cards and packaging.

5. Do UNO-related decks require license management in the US market?

- Concise answer: Yes; licensed UNO products are produced under license agreements, and partners must adhere to branding and licensing guidelines to maintain IP integrity.