Content Menu

● Overview of Perfume Box Manufacturers and Suppliers in Malaysia

● Why Choose Malaysian Perfume Box Manufacturers and Suppliers?

● Product Range Offered by Perfume Box Manufacturers and Suppliers

● Leading Perfume Box Manufacturers in Malaysia

● How Malaysian Suppliers Customize Perfume Boxes

● Market Trends Influencing Perfume Packaging in Malaysia

● Challenges Faced by Perfume Box Manufacturers and Suppliers

● How to Choose the Right Perfume Box Manufacturer in Malaysia

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What types of perfume boxes do Malaysian manufacturers produce?

>> 2. Are Malaysian perfume box manufacturers capable of OEM customization?

>> 3. How do Malaysian suppliers ensure the quality of perfume boxes?

>> 4. What sustainability measures are Malaysian perfume box manufacturers implementing?

>> 5. How long does it typically take to produce custom perfume boxes in Malaysia?

The perfume packaging industry plays a crucial role in enhancing the appeal and protection of fragrances, and Malaysia has emerged as a key player in this market. With specialized expertise in custom packaging solutions, Malaysian companies offer a wide range of perfume box manufacturing and supplier services to global brands, wholesalers, and producers. This article explores the top perfume box manufacturers and suppliers in Malaysia, highlighting their capabilities, product range, and how they serve international clients with OEM services.

Overview of Perfume Box Manufacturers and Suppliers in Malaysia

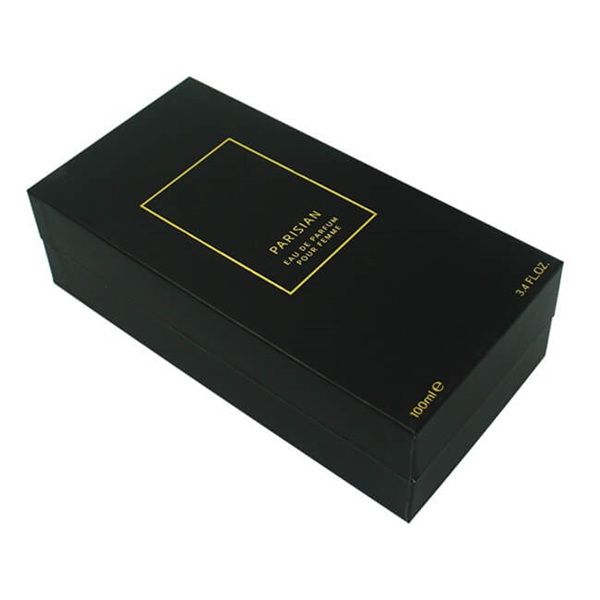

Malaysia's packaging manufacturers have adapted to the rising global demand for high-quality, innovative perfume boxes. Their offerings include custom-made designs such as rigid boxes, paperboard boxes, magnetic closure boxes, and eco-friendly packaging options. Malaysian manufacturers focus not only on aesthetics but also on functionality and durability, ensuring the boxes protect delicate perfume bottles while providing a visually appealing unboxing experience.

These companies are well-versed in various materials and finishing techniques, allowing them to cater to the specialized needs of luxury perfume brands, mid-market suppliers, and emerging fragrance houses. Their dedication to detailed craftsmanship and the use of premium materials often translate into packaging that complements and elevates the fragrance products they encase.

Why Choose Malaysian Perfume Box Manufacturers and Suppliers?

There are several compelling reasons international brands choose Malaysian perfume box manufacturers and suppliers:

- Custom OEM Services: Malaysian manufacturers excel in delivering tailored packaging solutions catering to brand specifications and current market trends, ensuring that every box reflects the unique identity and vision of the perfume brand.

- Competitive Pricing: Due to Malaysia's efficient manufacturing infrastructure and skilled labor force, production costs remain competitive without sacrificing quality, making it an attractive choice for brands seeking value.

- Advanced Technology: The integration of state-of-the-art printing and finishing techniques such as embossing, foil stamping, spot UV coating, and metallic foiling enables manufacturers to produce visually striking and tactilely pleasing packaging.

- Sustainability Focus: Many Malaysian producers have embraced green initiatives, including sourcing recycled materials, utilizing biodegradable inks, and implementing eco-friendly processes to satisfy global demand for sustainable packaging.

- Fast Lead Times: Efficient workflows and logistics expertise allow these manufacturers to meet tight production schedules and ship internationally with dependable timelines, an essential factor for brands on strict launch schedules.

These advantages combine to make Malaysian perfume box manufacturers a reliable and innovative choice for companies looking to outsource or expand their packaging requirements.

Product Range Offered by Perfume Box Manufacturers and Suppliers

Malaysian manufacturers provide a broad spectrum of perfume box types designed to cater to different market segments and branding strategies:

- Rigid Boxes: Commonly used for premium perfume products, these boxes are built with thick, solid materials that provide excellent protection and a luxurious feel. Custom inserts made of foam, velvet, or cardboard are often added to securely hold irregularly shaped perfume bottles.

- Paperboard Boxes: Lightweight and recyclable, paperboard packaging is favored by eco-conscious brands and those aiming for minimalist designs. These boxes are highly customizable in shape, size, and print finish.

- Magnetic Closure Boxes: Premium packaging styles featuring concealed magnets which offer smooth opening and closing functions, enhancing user interaction and perceived value.

- Foldable Carton Boxes: An economical choice that is easy to ship and store. These are often used for larger orders or promotional gift sets and can be printed with full-color branding designs.

- Specialty Inserts: Inserts protect fragile perfume bottles during transit and display, ensuring that products arrive in pristine condition. These inserts can be customized from various materials to suit different bottle shapes and weights.

- Decoration and Finishing Techniques: Malaysian manufacturers offer diverse decoration options including matte or gloss lamination, scent-impregnated coatings, spot UV highlights, embossing/debossing for logos and patterns, metallic foiling in gold or silver, and silk screening for precise graphics.

Such an extensive product range allows perfume brands from all price points and target markets to find suitable packaging that aligns with their identity and sustainability goals.

Leading Perfume Box Manufacturers in Malaysia

Several manufacturers in Malaysia differentiate themselves through their advanced manufacturing capabilities, client portfolios, and strong service models. These companies have established reputations by consistently meeting the diverse requirements of international perfume brands:

- Company A: Known for pioneering luxury rigid boxes, Company A specializes in integrating complex finishing techniques, including multi-layer embossing and customized inserts designed to showcase unique perfume bottle designs. Their clients include a range of prestigious perfume houses.

- Company B: Catering to the growing eco-conscious segment, Company B has developed innovative solutions using recycled kraft paper and biodegradable inks. They provide comprehensive OEM services for brands emphasizing sustainability.

- Company C: A leader in rapid production, Company C excels in foldable carton packaging with full-color printing capabilities. Their fast turnaround times support aggressive promotional campaigns and seasonal product launches.

- Company D: This manufacturer focuses on magnetic closure boxes and offers end-to-end design consulting services, helping brands craft premium packaging that enhances consumer experience and brand loyalty.

These manufacturers' expertise spans supply chain management, printing technology, design collaboration, and compliance with global packaging regulations, addressing every step in the perfume packaging process.

How Malaysian Suppliers Customize Perfume Boxes

Malaysian perfume box manufacturers closely collaborate with their clients through every phase of packaging development:

- Design Collaboration: Suppliers work with brand design teams to incorporate logos, color schemes, and unique visual elements that reflect the perfume's identity. Digital mockups and 3D prototypes are frequently utilized to ensure exacting detail before production.

- Material Selection: Depending on brand priorities—luxury appeal, sustainability, budget—manufacturers recommend appropriate paper stocks, coatings, and finishes.

- Prototyping and Sampling: To guarantee functionality and aesthetics, samples and prototypes are produced and reviewed. This iterative process helps identify improvements and refine details such as box structural integrity and print vibrancy.

- Production and Quality Control: During mass production, manufacturers adhere to rigorous quality assurance protocols, including color consistency checks, material durability tests, and package fit assessments.

- Logistics and Delivery: Packaging is shipped globally with care to maintain product integrity. Manufacturers commonly coordinate with freight forwarders to optimize shipping routes and customs clearance.

This client-centric approach ensures that the finished product meets both marketing vision and practical requirements for retail display, shipment safety, and consumer engagement.

Market Trends Influencing Perfume Packaging in Malaysia

The perfume packaging market in Malaysia is evolving alongside global trends. Key drivers reshaping manufacturer product offerings include:

- Sustainability Initiatives: With consumers increasingly demanding environmentally responsible products, many manufacturers have intensified efforts to use biodegradable or recycled materials and reduce plastic usage in packaging components.

- Minimalist Aesthetic: A strong design trend favors minimalist, sleek packaging that conveys sophistication through simplicity. Clean lines, subtle colors, and understated logos typify these designs.

- Smart Packaging Features: Adoption of interactive elements such as QR codes and Near Field Communication (NFC) chips embedded in packaging help perfume brands engage consumers with digital content, product authentication, and personalized marketing.

- Premium Finishing Enhancements: To differentiate luxury brands, decorative techniques like textured varnishes, metallic foils, embossed logos, and velvet touch coatings improve shelf presence and tactile experience.

- Customization and Limited Editions: Increasingly, brands are commissioning limited edition packaging to celebrate events or collaborations, and Malaysian manufacturers are equipped to deliver short-run productions with high customization levels.

These trends continue to influence how Malaysian manufacturers innovate and serve a global client base focused on both aesthetics and functionality.

Challenges Faced by Perfume Box Manufacturers and Suppliers

While Malaysia's perfume box industry is growing, it encounters challenges that manufacturers and suppliers must navigate:

- Material Availability: Finding sustainable raw materials that meet luxury standards and global certifications can be complex and affect production schedules.

- Balancing Cost and Innovation: Integrating cutting-edge packaging techniques without inflating costs remains a delicate art, especially for emerging brands.

- Compliance with International Norms: Navigating export regulations, environmental standards, and customs requirements adds operational complexity.

- Supply Chain Disruptions: Global logistics uncertainties can impact timely delivery and inventory management.

- Intellectual Property Protection: Ensuring brand designs and prototypes are protected against duplication requires secure manufacturing agreements and internal protocols.

Despite these hurdles, Malaysian manufacturers have adapted through strategic sourcing, quality control measures, and close customer engagement to maintain leadership in this sector.

How to Choose the Right Perfume Box Manufacturer in Malaysia

Choosing the appropriate Malaysian manufacturer involves multiple considerations:

- Experience with Perfume Packaging: Strong portfolio in perfume or cosmetic packaging signals familiarity with industry-specific requirements such as bottle protection and luxury presentation.

- Customization Capabilities: Assesses the ability to produce diverse box types, complex finishing effects, and prototype iterations.

- Quality Assurance Measures: Verifies certifications, testing procedures, and client testimonials for confidence in production standards.

- Sustainability Practices: Examines environmental credentials and material sourcing for brands prioritizing green packaging.

- Communication and Support: Values transparent, responsive communication and willingness to collaborate throughout the project lifecycle.

- Delivery Reliability: Considers lead times, logistics expertise, and ability to meet unforgiving launch deadlines.

Careful evaluation helps brands form strong partnerships with Malaysian manufacturers who can deliver packaging that supports commercial success.

Conclusion

Malaysia has become a hub for high-quality perfume box manufacturers and suppliers, offering extensive customizable solutions that align with the needs of international brands. The combination of skilled craftsmanship, innovative technology, and eco-conscious practices positions Malaysian suppliers as ideal partners for perfume companies seeking to enhance their packaging appeal and performance. By choosing a reputable Malaysian manufacturer, brands can ensure durable, stylish, and market-ready perfume boxes that capture consumer interest and loyalty.

Frequently Asked Questions (FAQs)

1. What types of perfume boxes do Malaysian manufacturers produce?

Malaysian manufacturers produce rigid boxes, paperboard boxes, magnetic closure boxes, foldable cartons, and specialty inserts designed for perfume bottles.

2. Are Malaysian perfume box manufacturers capable of OEM customization?

Yes, they offer comprehensive OEM services including custom design, materials selection, printing, finishing, and packaging solutions tailored to client needs.

3. How do Malaysian suppliers ensure the quality of perfume boxes?

They use advanced printing technology, quality materials, prototype sampling, and adhere to international quality standards to maintain high product quality.

4. What sustainability measures are Malaysian perfume box manufacturers implementing?

Many have incorporated eco-friendly materials such as recycled paper, biodegradable inks, and sustainable sourcing practices to reduce environmental impact.

5. How long does it typically take to produce custom perfume boxes in Malaysia?

Lead times vary but typically range from 3 to 6 weeks depending on order size, customization complexity, and raw material availability.