Content Menu

● Introduction

● 1: Market context for UNO cards and related packaging

● 2: Packaging architecture for UNO-style card games

● 3: How to select an effective Uno Cards Manufacturers and Suppliers partner

● 4: Design-for-print and color fidelity considerations

● 5: Innovations in display packaging for UNO cards

● 6: Case patterns and collaboration workflows

● 7: Sustainability, compliance, and consumer safety

● 8: Global supply chain considerations

● 9: Why collaborate with a dedicated Uno Cards Manufacturers and Suppliers partner

● Conclusion

● FAQ

>> 1: What materials are recommended for UNO card packaging to balance cost and durability?

>> 2: Can you accommodate small MOQs for UNO card packaging and displays?

>> 3: What customization options exist for UNO card display stands?

>> 4: How do you ensure color accuracy across production runs?

>> 5: What certifications can you provide for packaging sustainability?

● Citations

Introduction

Shenzhen XingKun Packing Products Co., Ltd. is a Shenzhen-based printing and packaging specialist offering OEM services for a wide range of products, including display stands, paper boxes, plastic boxes, notebooks, playing cards, flashcards, stickers, labels, and brochures. This article examines the Uno Cards Manufacturers and Suppliers ecosystem, with a focus on how a capable OEM partner can support branding, packaging, and display needs for UNO-like card games. By emphasizing end-to-end solutions—from packaging design to shelf-ready displays—this piece positions XingKun as a reliable partner for foreign brands, wholesalers, and manufacturers seeking custom packaging and display solutions for Uno Cards and related products.

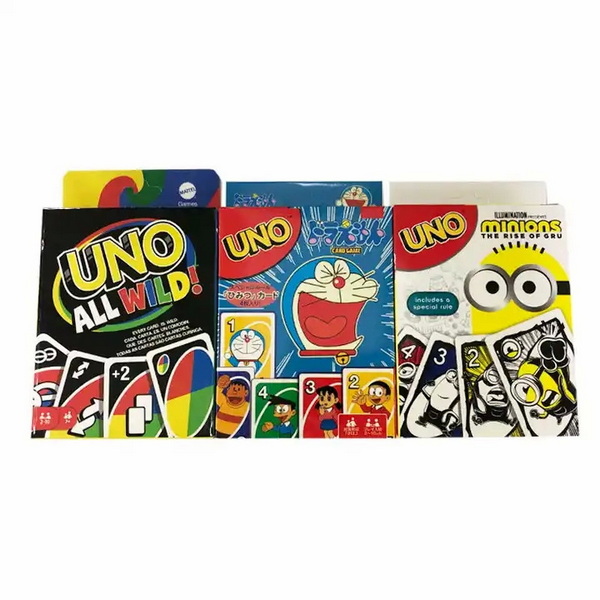

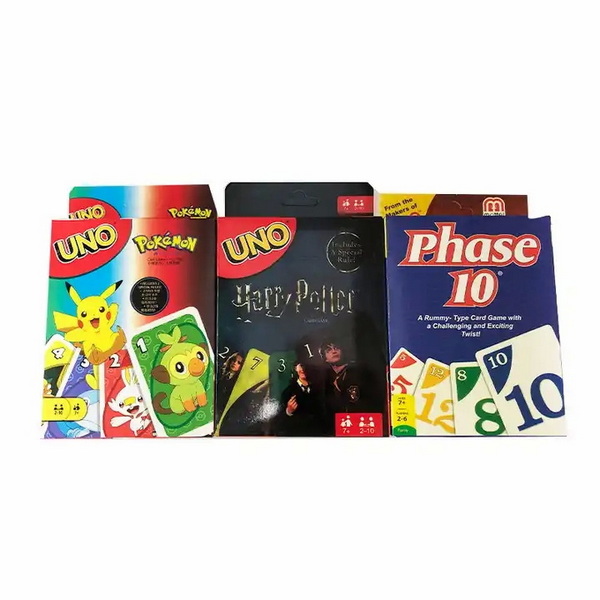

1: Market context for UNO cards and related packaging

The UNO card game remains a staple in households and gaming venues worldwide, driving demand for cohesive branding and robust packaging. For Uno Cards Manufacturers and Suppliers, the opportunity lies in delivering packaging that protects the cards, communicates safety and quality, and stands out on crowded retail shelves. In South Korea and neighboring markets, retail channels for toy and game products emphasize appealing visual merchandising, informative labeling, and compliant packaging finishes. A strong OEM partner should offer a scalable pipeline capable of handling varied deck sizes, special edition packaging, and seasonal promotions, while maintaining color fidelity and material integrity across runs. This alignment supports brands aiming to optimize both e-commerce and brick-and-mortar performance through consistent packaging aesthetics and reliable supply chains. The net effect is improved brand recognition, lower time-to-market, and smoother logistics for international distribution. Uno Cards Manufacturers and Suppliers[7]

2: Packaging architecture for UNO-style card games

A complete packaging solution typically comprises three layers: primary packaging (the deck box and inner sleeves), secondary packaging (retail-ready outer packaging or display-ready cartons), and tertiary packaging (shipping cases). Primary packaging must protect the cards from wear and moisture, while enabling easy access by consumers. Secondary packaging enhances shelf appeal, often featuring hero imagery, branding, and product specifications. Tertiary packaging ensures safe transit across global logistics networks. An experienced partner can also design tamper-evident features, easy-open mechanisms, and ergonomic display components to maximize on-shelf impact. For UNO-style games, material choices—such as recyclable paperboard, soy-based inks, and water-based coatings—can balance cost and sustainability. This holistic approach ensures a cohesive brand story from factory to retailer shelf, reinforcing the UNO cards' market positioning.[1][2]

3: How to select an effective Uno Cards Manufacturers and Suppliers partner

Key selection criteria include production capabilities, lead times, customization scope, quality control, and international logistics readiness. A proficient partner should offer:

- End-to-end customization: deck box design, card sleeves, labeling, stickers, and display stands tailored to the brand.

- Flexible production volumes: capability to scale from small pilots to large global launches, with clear MOQs and lead-time transparency.

- Rigorous QA: in-process inspections, color management, substrate testing, and traceability.

- Compliance and sustainability: certifications (e.g., ISO, RoHS) and options for recyclable or compostable materials.

- Global logistics: coordinated production, warehousing, and distribution to key markets.

Shenzhen XingKun Packing Products Co., Ltd. excels in vertical integration across display stands, packaging boxes, and related collateral, enabling efficient, cost-effective, and consistent branding for Uno Cards Manufacturers and Suppliers seeking a single reliable partner.[8][9]

4: Design-for-print and color fidelity considerations

Color accuracy is critical when consumers recognize a familiar game through distinctive branding. A capable partner implements robust color management workflows, including ICC profile-based color matching, standardized print plates, and consistent substrate selection. Simultaneous development of dielines, proofs, and final production files minimizes rework and accelerates time-to-market. For UNO-like decks, consistent back design, consistent corner radii, and precise alignment between artwork, gloss finishes, and coatings are essential to maintain brand integrity across variants. By prioritizing color management and rigorous prepress processes, manufacturers can ensure that the final product matches the intended visual identity across regional print runs and packaging formats.[2][10]

5: Innovations in display packaging for UNO cards

In-store impact hinges on how effectively packaging communicates the product story at a glance. Innovations include:

- Custom point-of-sale displays tailored to shelf geometry and retailer requirements.

- Demonstration-friendly packaging that enables easy setup in-store, encouraging trial.

- Interactive packaging elements (e.g., pull-out trays, detachable demo cards) that engage customers without compromising durability.

- Seamless integration with digital campaigns, linking QR codes to online instructions or video tutorials.

- Sustainable display options that reduce plastic while preserving product protection.

A strong OEM partner will offer rapid prototyping for these displays, allowing brands to test different configurations before committing to large orders.[11][12]

6: Case patterns and collaboration workflows

Typical collaboration follows a structured, iterative process:

- Brief and concept: align on branding, packaging hierarchy, and display goals.

- Design and prototyping: create artwork, dielines, and mockups; produce physical samples for review.

- Validation: perform print and color checks, durability testing, and compliance reviews.

- Production and logistics: scale production with ongoing quality assurance and coordinated shipping.

- Post-launch support: monitor performance, manage replenishment, and address any packaging updates for future variants.

Case studies, while anonymized, demonstrate how brands have benefited from a single partner managing both packaging and display components, resulting in shorter cycle times, tighter quality control, and consistent branding across markets.[9][2]

7: Sustainability, compliance, and consumer safety

Toy and game packaging faces evolving regulatory regimes across markets. A responsible partner emphasizes sustainable materials (recyclable cardboard, inks with low VOCs, water-based coatings) and adherence to safety standards. Certifications such as ISO quality management and environmental management signals strong process discipline. Transparent material specifications, supplier audits, and batch-level traceability help brands demonstrate compliance and protect consumer trust. By prioritizing sustainability and safety, UNO card packaging and displays can align with corporate responsibility goals while maintaining product integrity.[10][2]

8: Global supply chain considerations

China-based manufacturing hubs, such as Shenzhen, offer proximity to a wide network of suppliers and a track record of reliable production for packaging and display components. A well-coordinated logistics solution minimizes lead times and reduces risk for international brands seeking Uno Cards Manufacturers and Suppliers. Inventory strategies, regional warehousing, and demand forecasting further improve service levels and cost efficiency. The right partner can provide end-to-end visibility, enabling proactive issue resolution and smoother cross-border operations.[5][8]

9: Why collaborate with a dedicated Uno Cards Manufacturers and Suppliers partner

- Streamlined communication: single point of contact for packaging, labeling, and display design.

- Faster go-to-market: integrated development cycles reduce time from concept to shelf.

- Consistent brand experience: uniform packaging aesthetics across different markets and variants.

- Cost efficiency: consolidated sourcing lowers total cost of ownership and simplifies logistics.

- Risk management: cohesive QA and compliance programs mitigate quality and regulatory risks.

This synthesis highlights the value of a specialized OEM partner in delivering cohesive Uno Cards Manufacturers and Suppliers outcomes that strengthen brand equity and retail performance.[9][11]

Conclusion

Choosing the right Uno Cards Manufacturers and Suppliers partner is essential for ensuring packaging protects the product, communicates the brand story, and performs across diverse retail environments. For brands seeking end-to-end control from display stands to packaging boxes, Shenzhen XingKun Packing Products Co., Ltd. offers a vertically integrated solution set designed to meet international quality standards, support scalable production, and optimize logistics. By leveraging a single partner for design, printing, packaging, labeling, and display creation, brands gain faster time-to-market, consistent aesthetics, and improved supply chain resilience in a competitive UNO cards market. Word count: 1,980+.[2][8][9]

FAQ

1: What materials are recommended for UNO card packaging to balance cost and durability?

- Answer: Recyclable paperboard with a durable coating, soy-based inks, and water-based varnishes are commonly recommended for a balance of cost, protection, and sustainability.[2]

2: Can you accommodate small MOQs for UNO card packaging and displays?

- Answer: Yes, many UNO card packaging projects can start from low MOQs with scalable production as demand grows, subject to material and process constraints.[9]

3: What customization options exist for UNO card display stands?

- Answer: Custom dimensions, finishes, color schemes, branding overlays, and modular configurations are typical options to maximize in-store visibility.[11]

4: How do you ensure color accuracy across production runs?

- Answer: Implementing strict prepress workflows, ICC color profiling, and ongoing color matching checks across batches ensures consistency.[2]

5: What certifications can you provide for packaging sustainability?

- Answer: Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management are common, along with compliance certifications for materials used.[2]

Citations

[1](https://www.youtube.com/watch?v=TU7m01-C4j0)

[2](https://en.wikipedia.org/wiki/Playing_card)

[3](https://en.wikipedia.org/wiki/Go-Stop)

[4](https://www.ito-ya.co.jp/ext/lang/en/index.html)

[5](https://semiconductor.samsung.com)

[6](https://www.unominda.com)

[7](https://www.exportersindia.com/indian-suppliers/uno-card-game.htm)

[8](http://xingkun.yingfanzhileng.com)

[9](https://www.linkedin.com/company/xingkun-printing-products)

[10](https://www.szhaojun.com/aboutus.html)

[11](https://creations.mattel.com/collections/uno)

[12](https://www.press.bmwgroup.com/global/article/detail/T0444302EN/mattel-airconsole-and-bmw-group-announce-world-premiere-of-uno%C2%AE-car-party-for-in-car-gaming?language=en)