Content Menu

● Introduction

● Market Context in Southeast Asia

● OEM capabilities for Uno decks

● Shenzhen XingKun Packing Products Co., Ltd: OEM packaging and display partner

● Quality assurance, compliance, and certifications

● Distribution and supply chain considerations

● Integration with global OEM partners

● Case for Chinese and Thai collaboration

● Sustainability and responsible sourcing

● Future trends in UNO card manufacturing and packaging

● Conclusion

● FAQ

>> 1) How can a brand begin an OEM project for UNO cards in Thailand?

>> 2) What packaging options are available for UNO decks, and how do they influence retail performance?

>> 3) Are Thai UNO card packaging suppliers compliant with international safety and quality standards?

>> 4) Can small brands order prototypes or pilot runs of UNO card decks and packaging?

>> 5) What role do multimedia marketing assets play in UNO card launches, and how can suppliers support these efforts?

Introduction

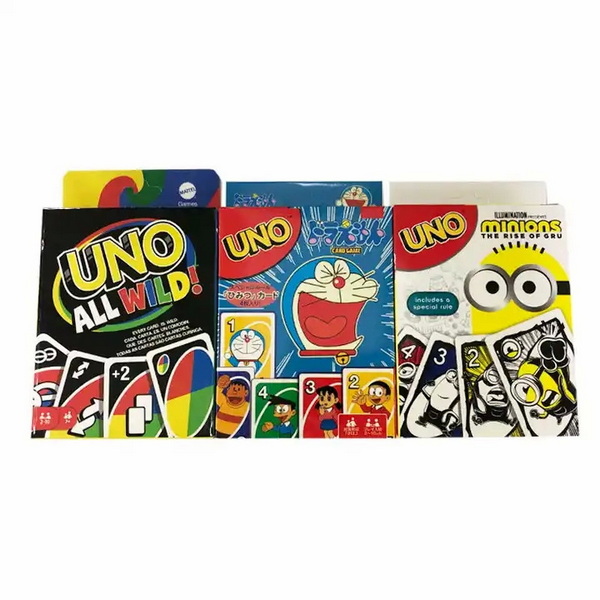

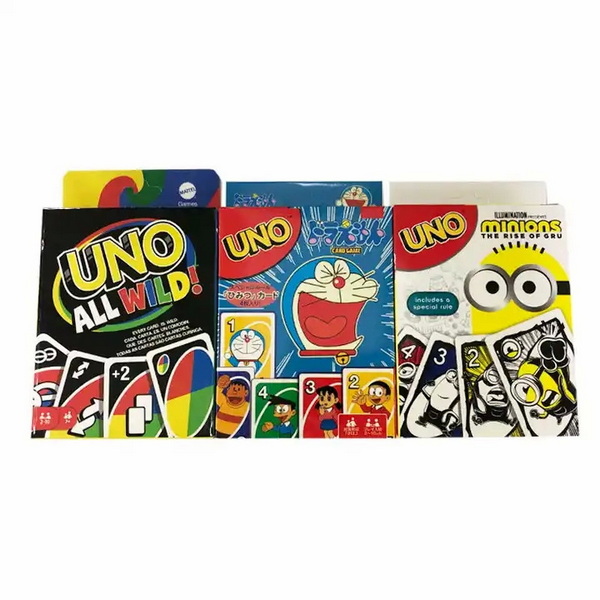

Uno Cards have become a global staple for family game nights, classroom activities, and brand-promotional campaigns. As demand for customized playing cards and attractive packaging grows, manufacturers offering OEM services in Thailand have gained prominence. This article examines the landscape of Uno Cards Manufacturers and Suppliers in Thailand, with emphasis on customized production, packaging, and branding possibilities, as well as the role of international partnerships that enable high-quality OEM solutions for Uno Cards Manufacturers and Suppliers worldwide. It also highlights the capabilities of Shenzhen XingKun Packing Products Co., Ltd as a trusted OEM partner for packaging, display solutions, and related accessories.

Market Context in Southeast Asia

Thailand serves as a strategic hub for game and packaging production in Southeast Asia, supported by a skilled workforce and established logistics networks. Local factories often collaborate with international brands to deliver turnkey OEM services, including card printing, deck customization, and packaging design. For buyers seeking Uno Cards Manufacturers and Suppliers, access to licensed editions, themed variants, and tailored packaging is a core advantage of sourcing from this region. The market also reflects regulatory considerations and safety standards pertinent to consumer games and printed products, underscoring the importance of working with reputable manufacturers that adhere to international quality requirements.

OEM capabilities for Uno decks

Leading manufacturers and packaging providers in Thailand offer a range of OEM services that cover both the cards themselves and the ancillary packaging. Key capabilities include:

- Card printing and lamination: high-quality print runs on standard 108-card decks or customized counts, with options for matte or glossy finishes, rounded corners, and durable lamination.

- Card stock and safety: selection of card stock grade, inks, and coatings that comply with safety standards for children's products.

- Themed and licensed editions: production of themed decks aligned with popular licenses or custom brand themes, including artwork integration and color management.

- Packaging design and production: creation of retail-ready packaging, display-ready boxes, and compatible accessories such as card organizers, blister packs, and header cards.

- Display solutions: production of point-of-sale displays, shelf-ready packaging, and display stands to maximize on-shelf visibility for UNO cards.

- Finishing and QA: final inspection, color matching, and durability testing to ensure consistency across batches.

Shenzhen XingKun Packing Products Co., Ltd: OEM packaging and display partner

Shenzhen XingKun Packing Products Co., Ltd specializes in customized packaging, display solutions, and OEM services for international brands. Their strengths lie in:

- Tailored packaging design for UNO decks, enabling brand differentiation on store shelves.

- Printing and customization options for boxes, sleeves, inserts, and supporting promotional materials.

- Coordinated supply of display racks, header cards, and point-of-purchase features to optimize merchant visibility.

- Flexible production volumes suitable for both small pilots and large-scale launches.

- Strong collaboration with overseas brands through end-to-end packaging solutions that align with global branding standards.

Quality assurance, compliance, and certifications

For UNO card products destined for global markets, quality assurance is essential. Reputable manufacturers in Thailand typically implement:

- Material safety testing for inks, coatings, and card stock.

- Durability and bend tests to ensure long-lasting decks in consumer use.

- Compliance with international toy and game safety standards where applicable.

- Transparent production traceability and clear communication about lead times, order quantities, and return policies.

Distribution and supply chain considerations

- Proximity to major Asian markets can reduce lead times and logistics costs, facilitating faster replenishment for retailers.

- Local and regional distributors often offer warehousing and cross-docking services to support international shipments.

- Packaging options can be tailored to meet regional retail requirements, including compliance with local labeling and information standards.

Integration with global OEM partners

For brands seeking comprehensive UNO card solutions, partnerships with packaging experts can streamline product launches. OEM collaborations with packaging specialists enable:

- Consistent brand identity across product and packaging assets.

- Efficient adaptation of artwork for packaging formats and regional markets.

- Coordinated marketing materials, including in-store promotions and online assets.

- End-to-end project management from design concept to finished goods delivery.

Case for Chinese and Thai collaboration

Cross-border collaboration can enhance production efficiency and offer competitive pricing for UNO card packaging and display components. When a brand engages with Thai manufacturers for card-related packaging, and partners with a Chinese packaging specialist for printed components and display solutions, the result can be a fully integrated, cost-effective supply chain. This setup aligns with the core strengths of Shenzhen XingKun Packing Products Co., Ltd as a packaging and OEM service provider.

Sustainability and responsible sourcing

Growing awareness of environmental impact leads some manufacturers to explore sustainable materials, recyclable packaging, and responsible sourcing for card stock and inks. Buyers can request environmentally friendly production options, such as recycled paperboard packaging and low-VOC inks, while maintaining print quality and product durability.

Future trends in UNO card manufacturing and packaging

- Increased demand for customization: brands seek decks that resonate with regional audiences through localized artwork and packaging designs.

- Enhanced packaging security: tamper-evident and child-safe packaging features become more common to protect product integrity.

- Digital design workflows: seamless file handoffs between brands and manufacturers to accelerate proofs and approvals.

- Integrated marketing assets: packaging design aligned with social media campaigns and unboxing videos to boost consumer engagement.

Conclusion

Thailand remains a vital hub for UNO cards manufacturing and packaging, supported by a robust ecosystem of local producers and international OEM partners. The combination of customization capabilities, packaging expertise, and proximity to key markets offers compelling value for brands seeking reliable UNO Cards Manufacturers and Suppliers. By leveraging the strengths of experienced packaging experts and strategic OEM partners, such as Shenzhen XingKun Packing Products Co., Ltd, brands can deliver compelling, on-shelf UNO products with strong branding, durable construction, and engaging packaging that resonates with diverse consumer groups.

FAQ

1) How can a brand begin an OEM project for UNO cards in Thailand?

- To start an OEM UNO project in Thailand, engage a reputable local packaging and printing partner for end-to-end services (concept to delivery), align on artwork, packaging, and quantity, and establish clear milestones, timelines, and QA procedures with the partner.

2) What packaging options are available for UNO decks, and how do they influence retail performance?

- Available packaging options include retail-ready boxes, slipcases, header cards, and display-ready cartons; these choices affect shelf appeal, protection, and cross-merchandising potential, influencing consumer attention and sales.

3) Are Thai UNO card packaging suppliers compliant with international safety and quality standards?

- Reputable Thai packaging suppliers typically adhere to international safety and quality standards, conducting material safety tests, color management, and durability checks to meet global buyer requirements.

4) Can small brands order prototypes or pilot runs of UNO card decks and packaging?

- Yes, many Thai suppliers accommodate small-batch prototypes or pilot runs to validate designs, materials, and packaging concepts before full-scale production.

5) What role do multimedia marketing assets play in UNO card launches, and how can suppliers support these efforts?

- Multimedia assets such as videos and high-quality imagery accelerate product awareness and engagement; suppliers can provide ready-to-use digital assets, enhanced product photography, and unboxing demonstrations to support launches.