Corrugated Box – The Master Guide

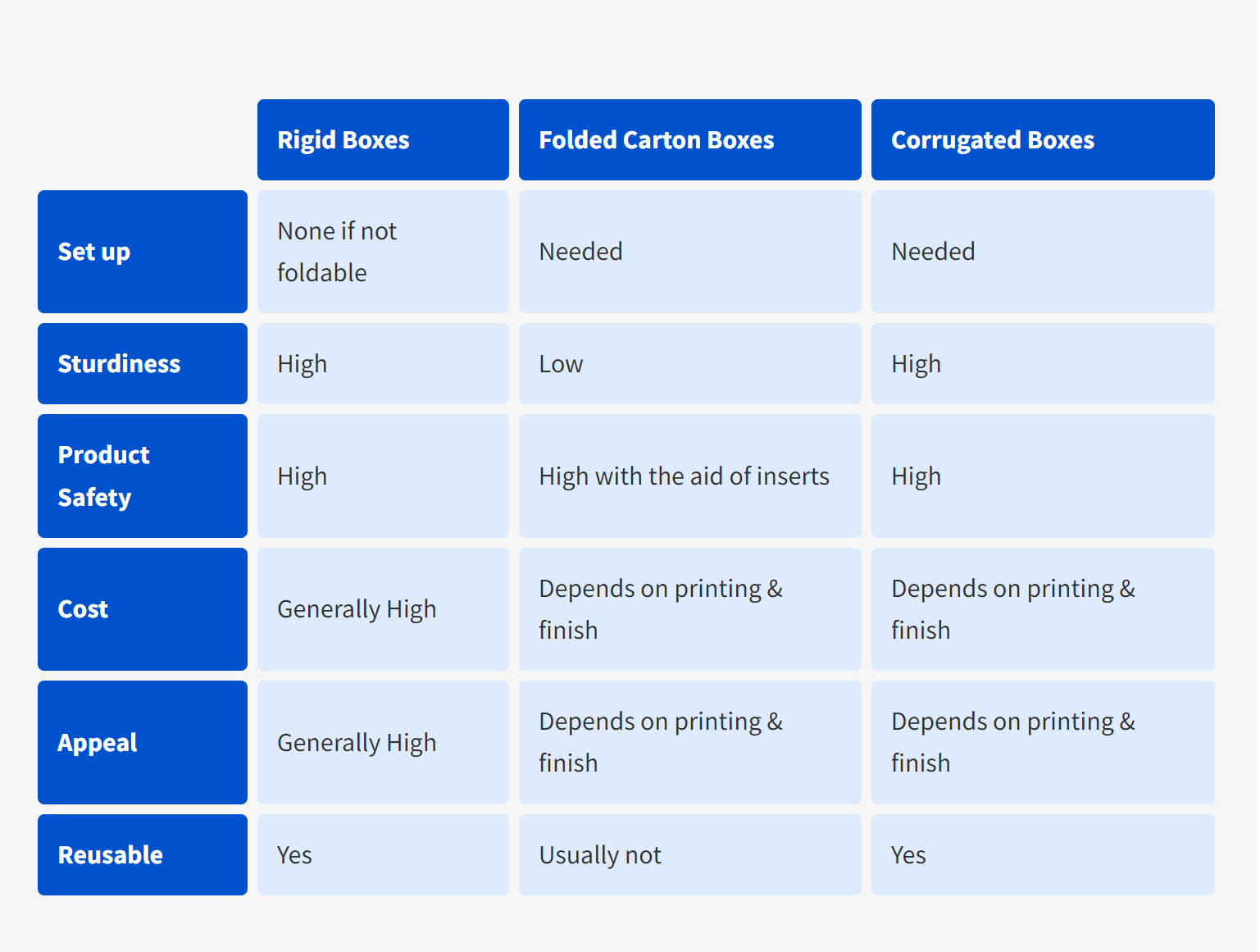

When you think of cardboard, you might assume it is just one type of packaging material. However, there is more to it than that. Cardboard is one type of material, and corrugated cardboard is another. Both materials are often confused with one another but serve different purposes depending on the product.

In this post, we will explore the differences between cardboard and corrugated cardboard, go in-depth into the various aspects of corrugated material, look into quality control, and discuss the benefits and uses of such material. By the end of this article, we hope to give you a better understanding of corrugated boards so you can make the best decision for your product’s packaging!

Corrugated Definition

Before we begin, let us define what a corrugated box is. Simply put, these boxes are made from sheets of corrugated cardboard, a prevalent shipping option for its protection and durability. In fact, 95% of all shipped products in North America use corrugated material! But what is corrugated cardboard?

Corrugated cardboard, or corrugated fiberboard, is a sturdy packaging material typically made from three layers of kraft paper. The outer layers are called liner boards, and the wavy layer is called flute. Adding additional layers for protection is also possible with corrugated, which we will discuss in more detail later.

Corrugated vs. Cardboard – What’s the Difference?

Now that you know what corrugated packaging is and how common it is in shipping, you may wonder what the difference is between corrugated and cardboard. We’ve mentioned briefly that corrugated cardboard differs from cardboard, but let us unpack this topic further.

Cardboard is generally made of thick paper stock or heavy paper pulp. It’s typically used in folded cartons for smaller product packaging but can also be used as structural support inside a box to keep its shape during transit. However, cardboard by itself is not very protective.

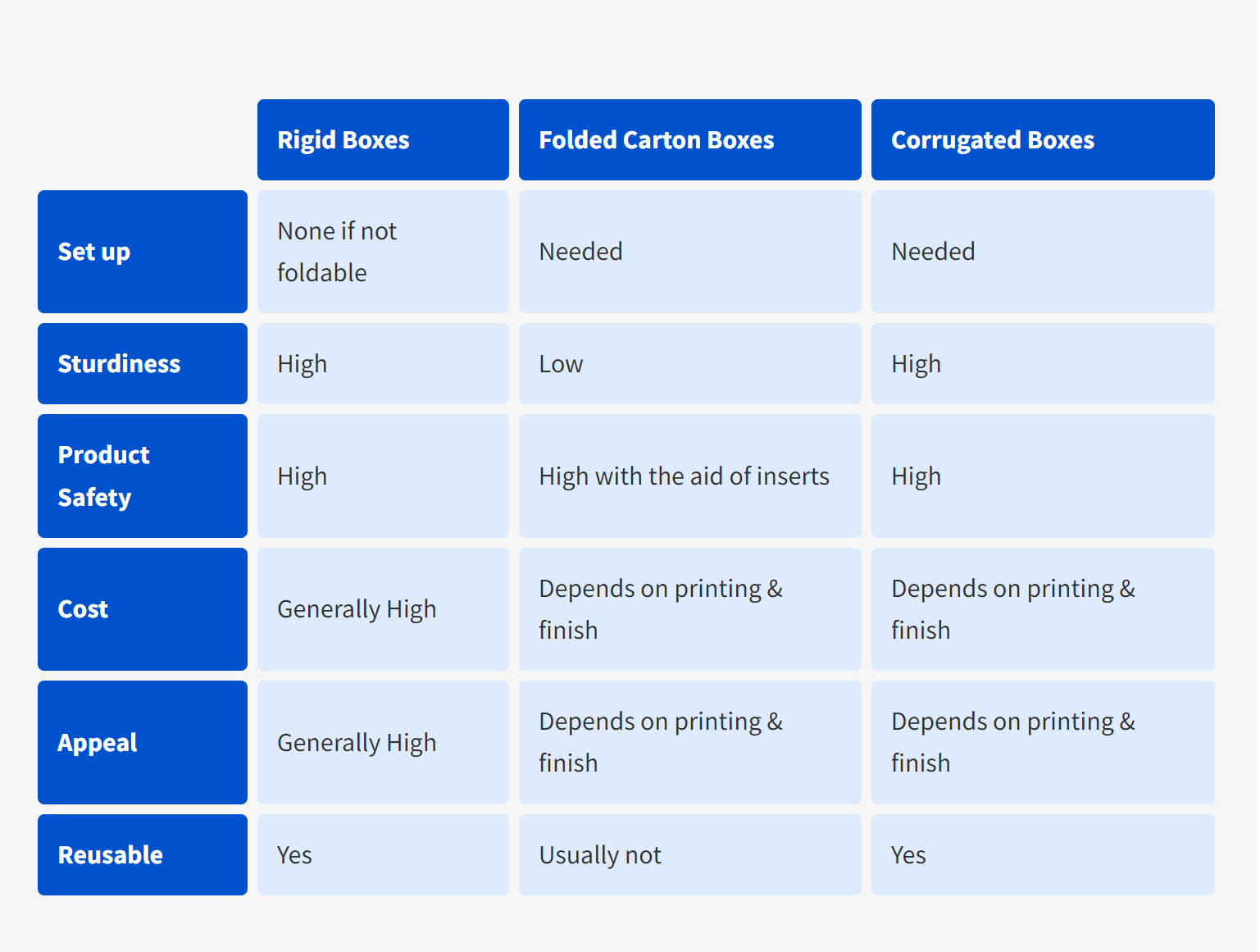

Corrugated, on the other hand, is different. It has three fiberboard layers, offering increased durability, protection, and versatility. This box material is among the best options whether your company is shipping large packages or sending a few products. Still unsure of the difference? Check out the chart below for a comparison!

Corrugated Construction – Paper Liners and Flute Grades

With a better understanding of corrugated materials, it should be less daunting now to take an even closer look at the types of corrugated options available, starting with the kinds of paper liners.

Kraft paper liners consist of 70-80% “virgin” chemical pulp fiber, which results in a top paper grade that is very stiff and durable. Kraft paper is the most sustainable option out of all the types of paper available, but it is also the most costly.

Test paper liners are less expensive than Kraft because they use more recycled fiber content, resulting in less durability. The higher recycled fiber content also makes the paper more difficult to print on, but it is very common to use test paper as the inner liner board of a corrugated box.

The last paper option is flute paper, available in Semi-Chem and Waste Based Fluting. Semi-Chem uses virgin fibers and a neutral sulphite semi-chemical process, while Waste Based Fluting uses 100% recycled fibers.

But speaking of flute paper, now is a good segue into the different flute grades available, too!

Corrugated Flute Grades

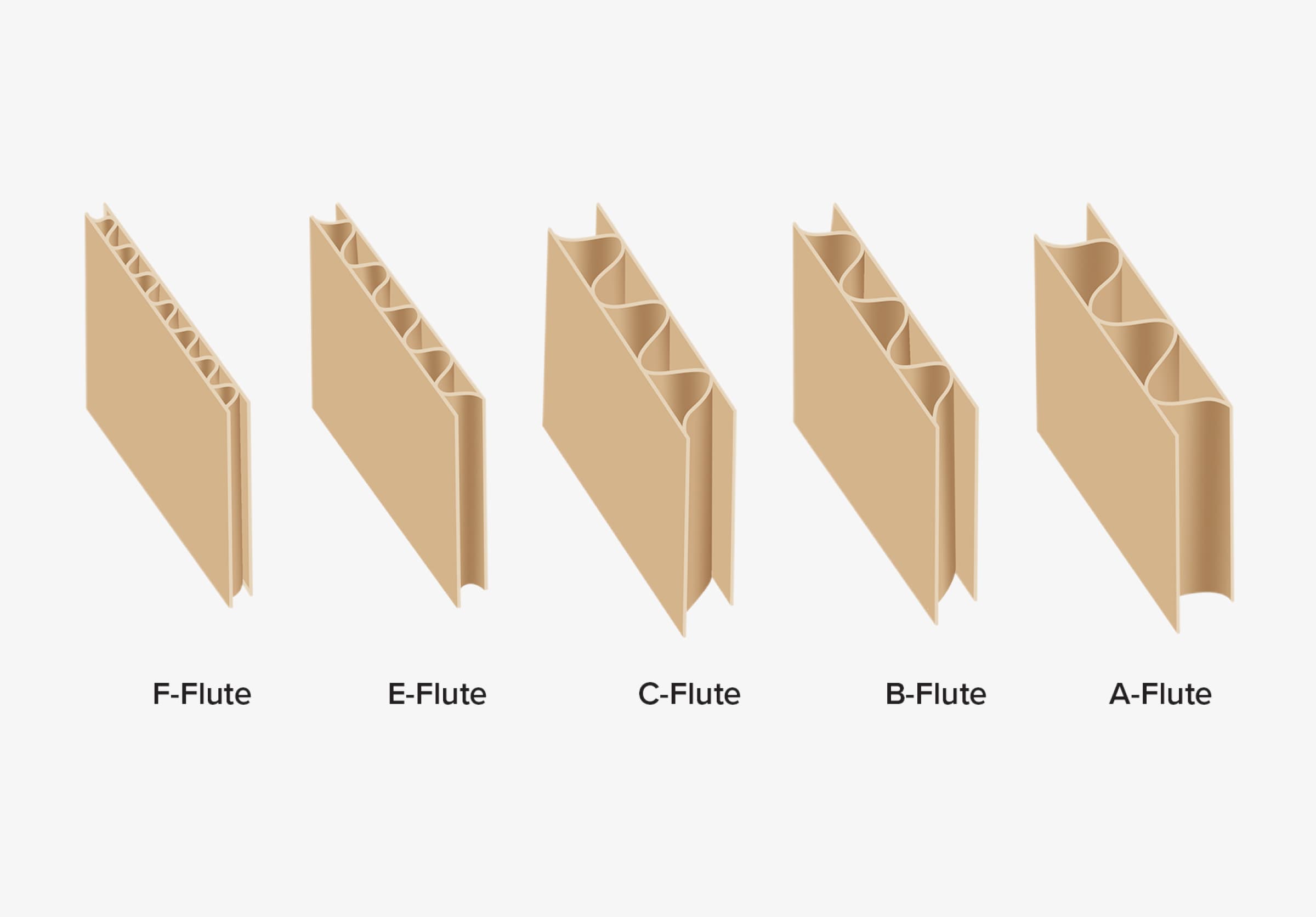

Corrugated flute is similar to liner boards save for the construction.

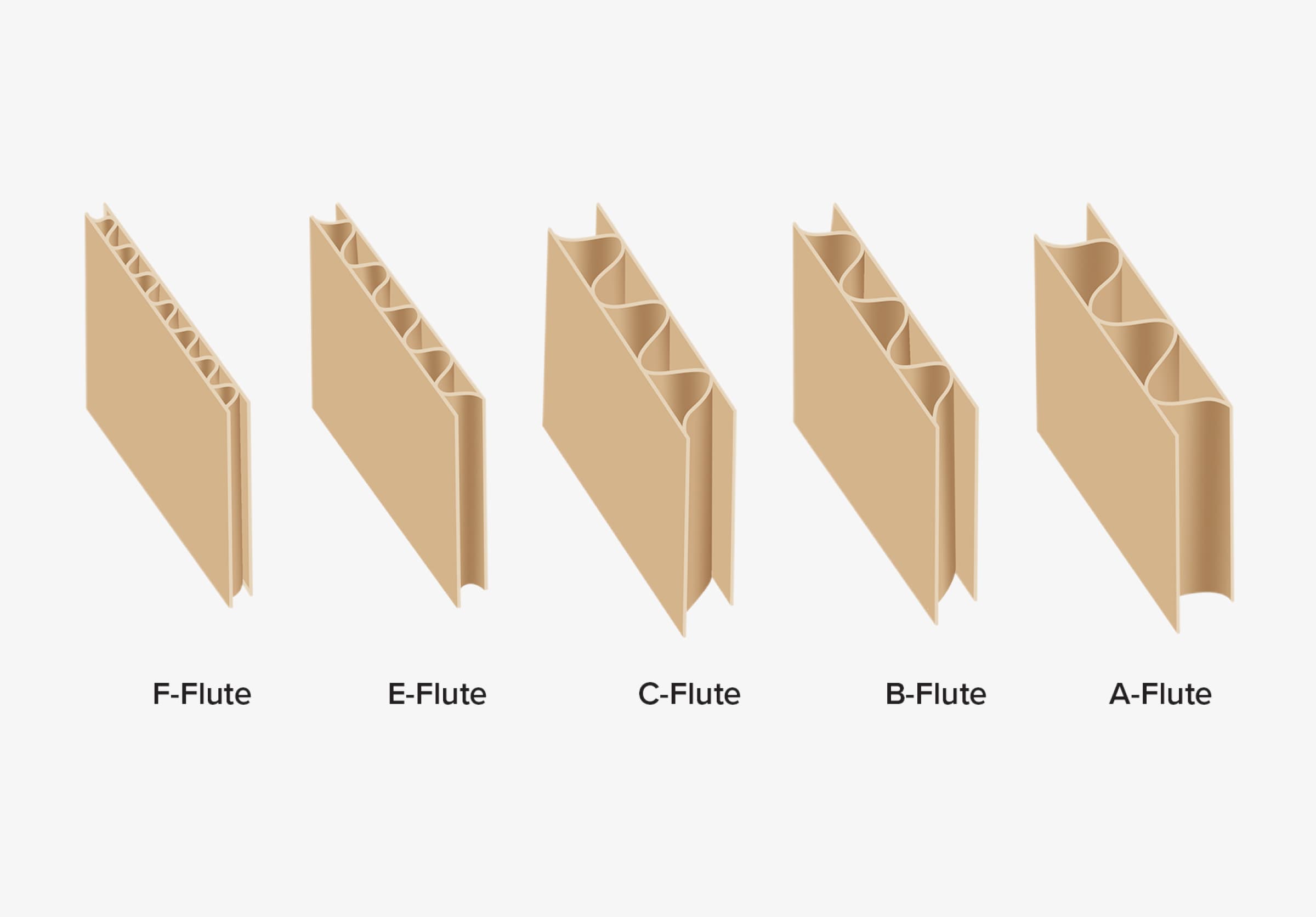

Corrugated flute provides cushioning, strength, and compression-resistant qualities to your package depending on the different grades, allowing for even more customization with your packaging. But before we examine each flute grade in detail, look at our corrugated flute chart for a quick visual comparison:

A-Flute – 1/4” is the first type of corrugated flute. This flute grade has the highest protection and cushion qualities. It is very good at handling compression and stacking and is often used for packaging fragile items.

B-Flute – 1/8”. This flute appears much thinner than others but is still quite strong, with excellent puncture and crush resistance. B-flute has outstanding all-around performance for various packaging or as additional material for padding and dividing. It even has a flatter surface for higher-quality printing and easy die-cutting.

C-Flute – 3/16” is flexible and one of the corrugated boxes’ most versatile flute grades. It has average crush resistance, stacking strength, and printing properties. You have likely seen C-Flute used for shipping boxes but also for packaging glass, dairy, and furniture products.

E-Flute – 1/16” is not typically used for shipping. E-flute thickness is on the thinner side of flute grades, so it is often used as an alternative for paperboard folding cartons. However, you may still use E-Flute for cosmetics, fragile glass, ceramics, and other small and delicate products. E-Flute has excellent compression strength, crush resistance, and a relatively flat surface for high-quality printing applications.

F-Flute – 1/32” has protective qualities similar to E-Flute but with an even smoother surface for high-quality printing. It is common for you to use F-Flute for clamshell packaging in the US fast-food industry, but in Europe, this grade of corrugated fluting is a standard option for specialty and retail packaging.

Corrugated Cardboard Thickness and Style

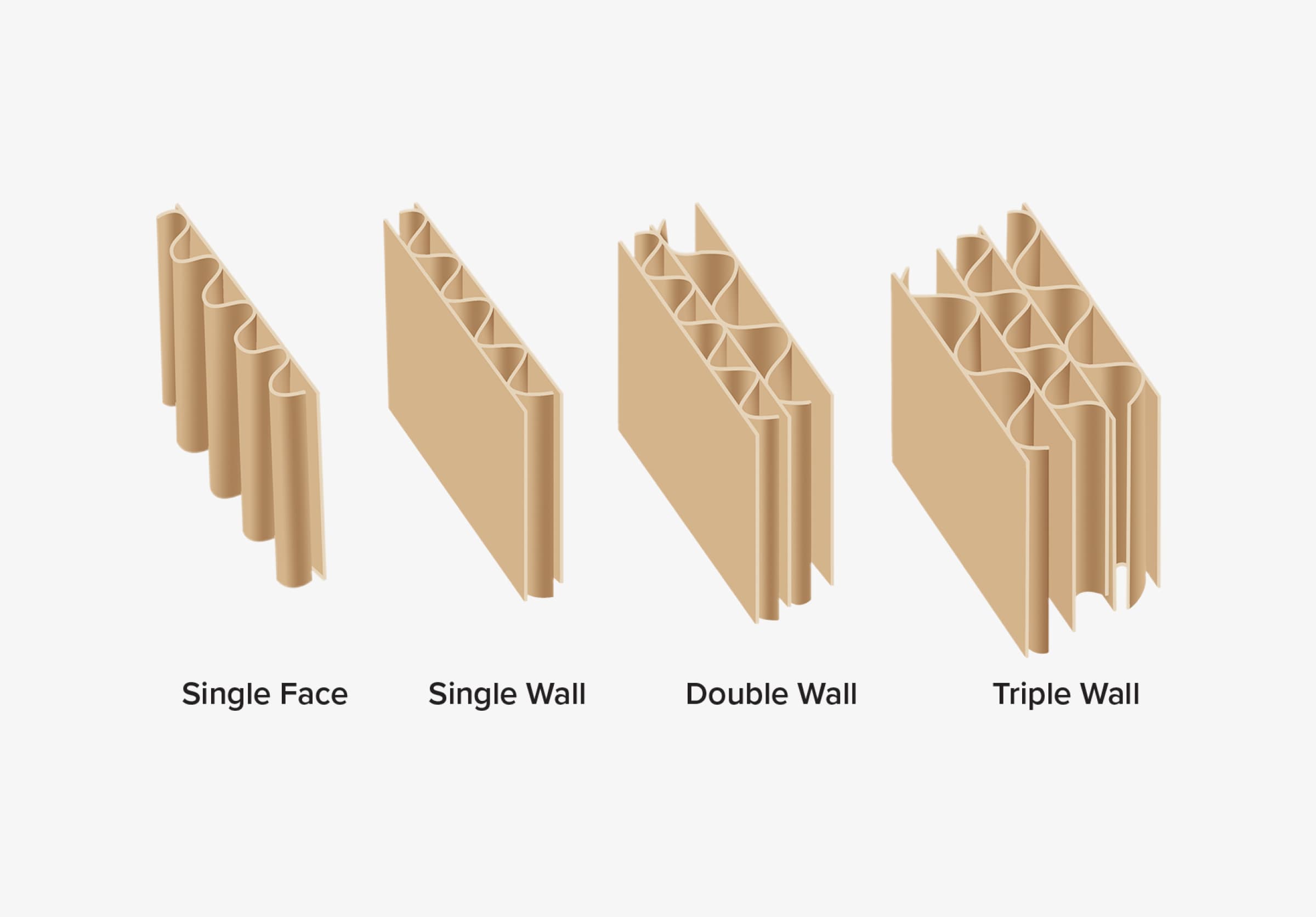

Now that we’ve covered the different types of paper liners and flute grades, it’s time to look at thickness! Below is a summary of the standard thickness options available:

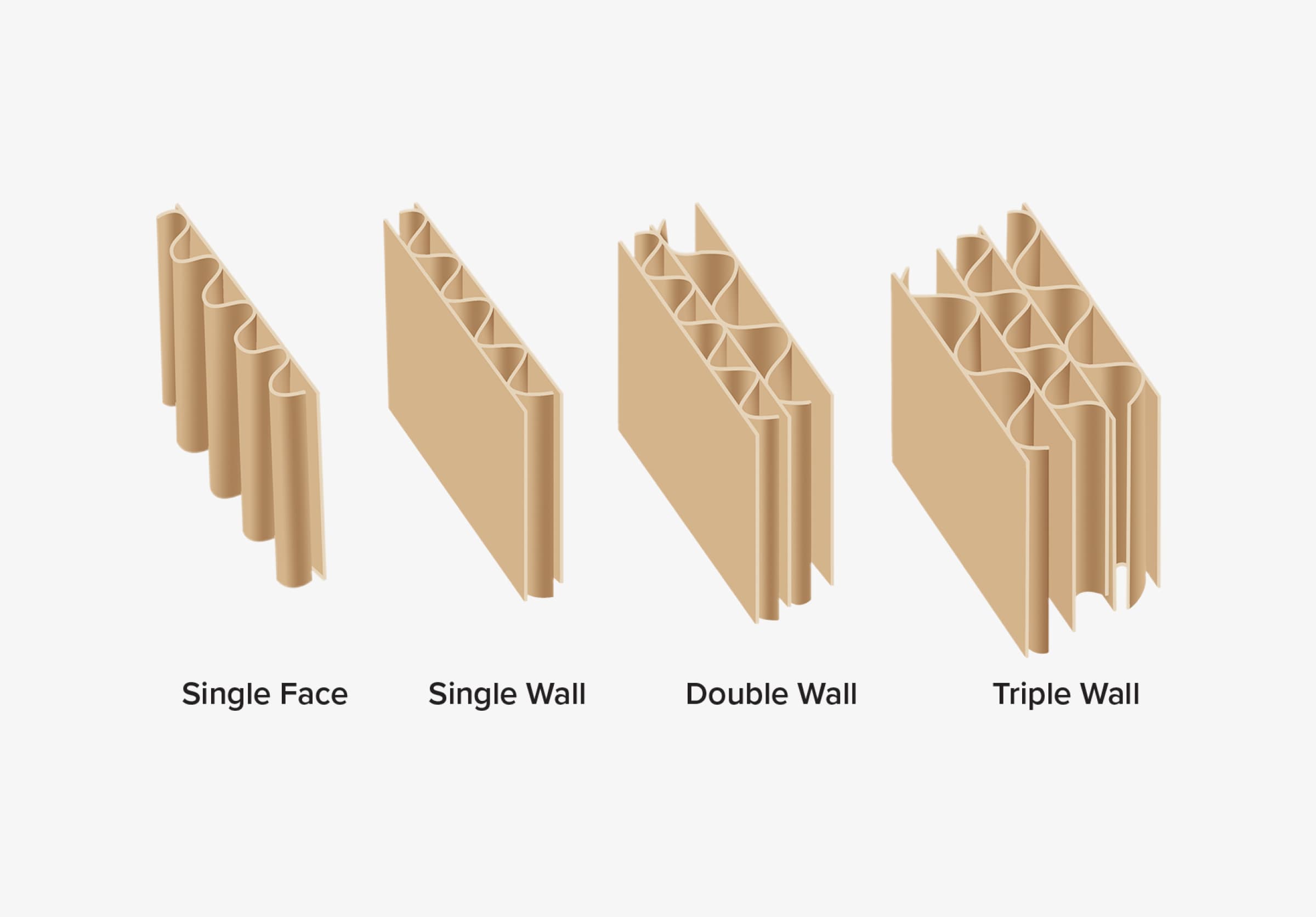

Liner Board – The ‘face’ of the fiberboard sheet. You glue the flute onto this board.

Single Face – Consists of one liner board with glued flute visible on one side.

Single Wall – The most common thickness. Two liner boards with fluted fiberboard glued in between.

Double Wall – Three sheets of liner board and two fluted fiberboards in between.

Triple Wall – Four sheets of liner board and three fluted fiberboards in between. This option can withstand heavier weights up to almost 300 lbs but is less flexible.

Examining a little further with double and triple walls, different combinations of flute grades are possible with these options. Some industry standard combinations include:

AC Flute – A mix of the two most protective corrugated grades. AC Flute is excellent if you need extra protection for harsh shipping and handling processes.

BC Flute – An outstanding all-around performer, this combination provides high-level transit protection and is common for shipping boxes.

EB Flute – Provides superior transit strength and safety, while the outer E-Flute allows for an excellent, high-quality printing surface.

Box Styles

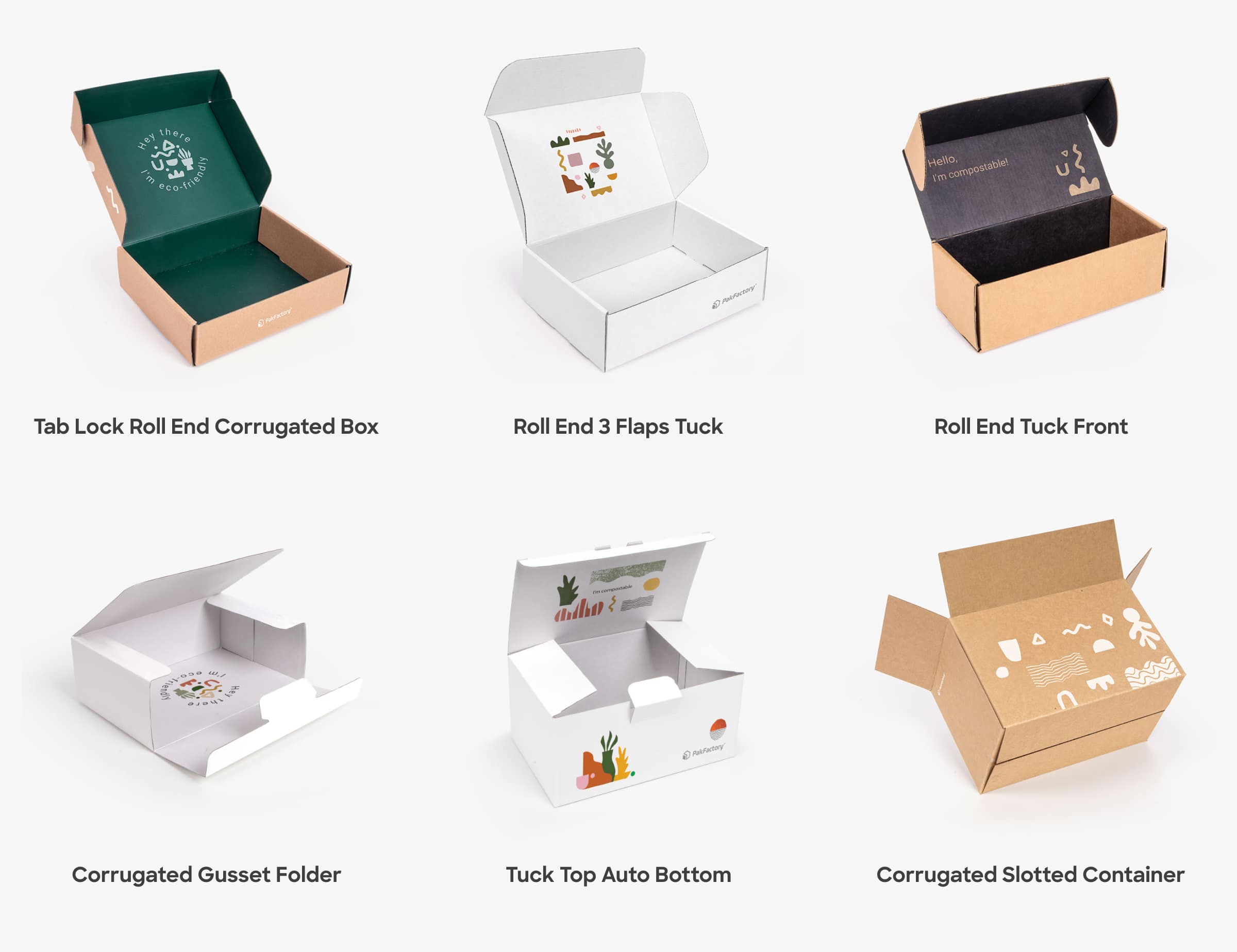

With everything from construction to thickness covered, the style of boxes is the last topic to cover before moving on to quality control. By combining layers, customizing flute grades, or adding interior padding, corrugated boxes can fit any packaging need.

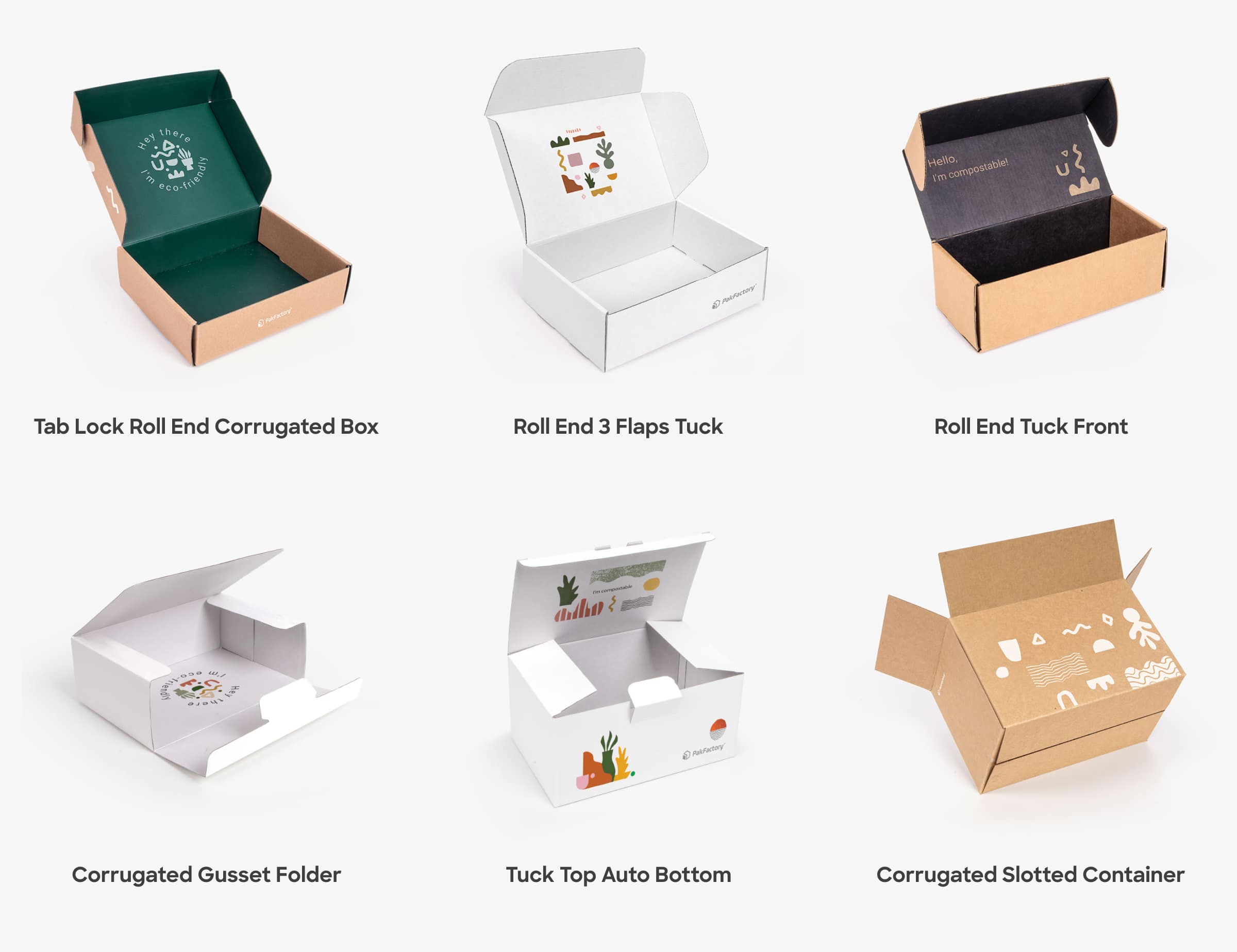

Custom corrugated boxes meet any specific requirement of the user, but below are some common styles for corrugated packages:

Quality Control Tests

With the sheer amount of design and customization options available at your fingertips, there might be many questions about protection. Corrugated boxes are subject to stress and impact during packing, shipping, and storage, so there needs to be ways to test your custom package’s strength.

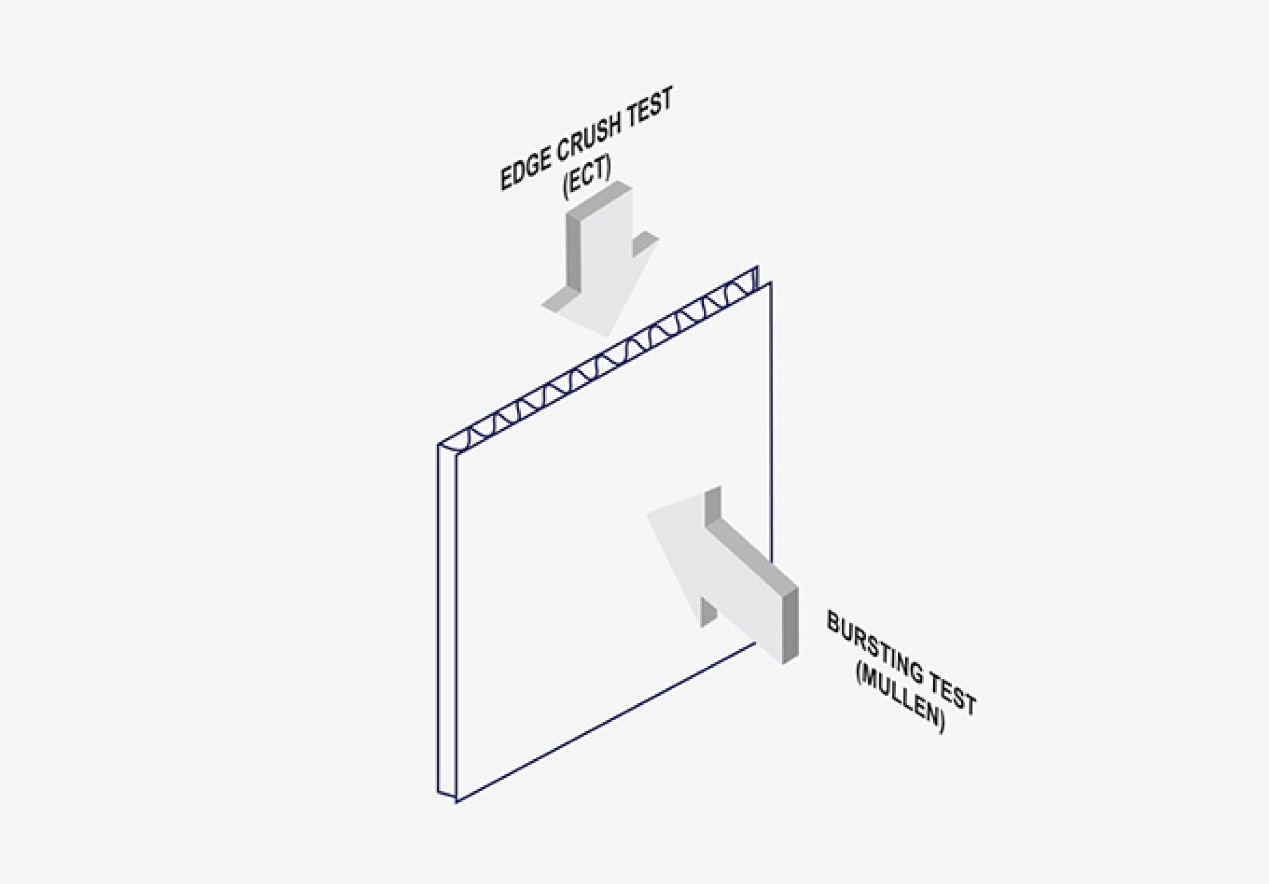

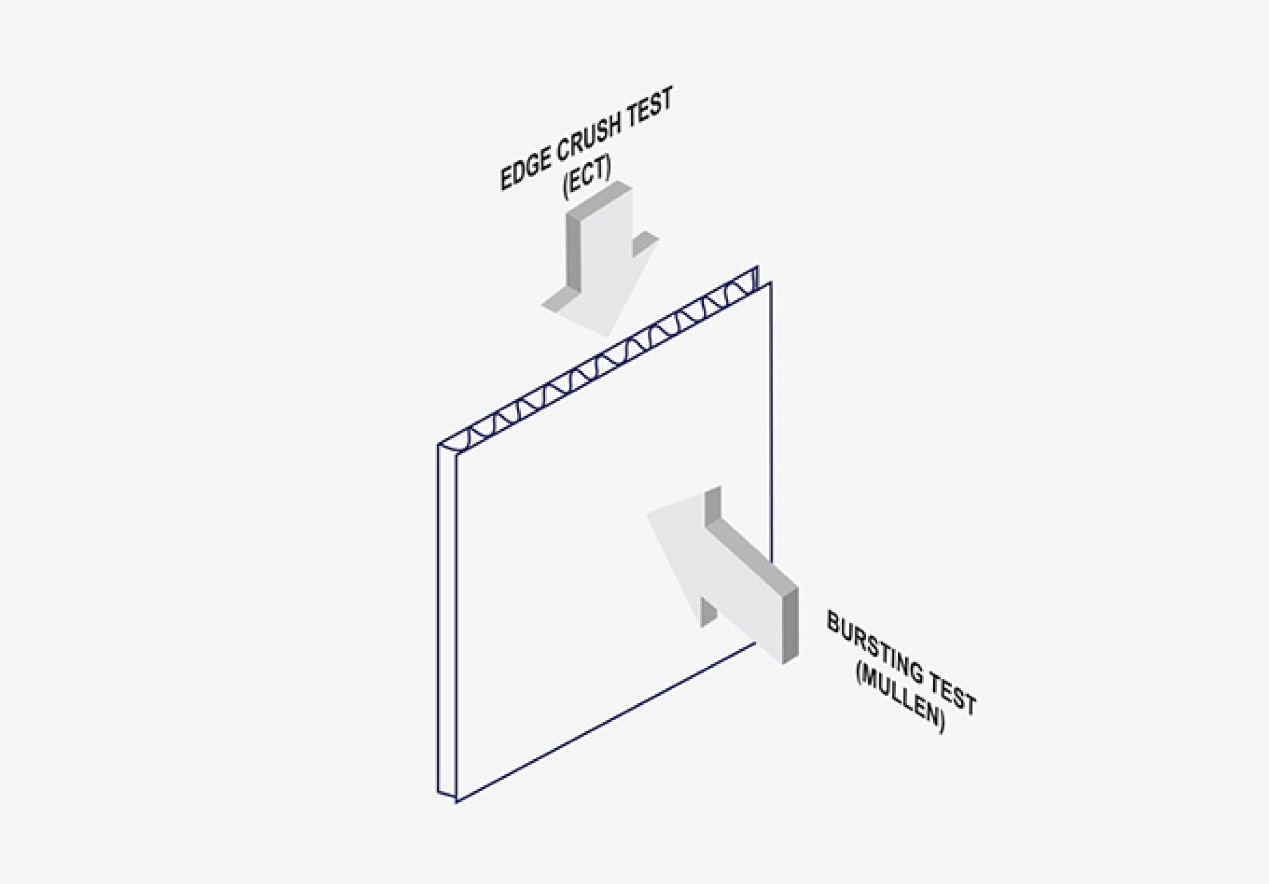

Some standard tests include the Edge Crush, Flat Crush, and the Burst Test.

The Edge Crush Test is one of the essential tests for corrugated packaging. As the name implies, force is applied perpendicular to the edge of the corrugated board until it buckles. The results ensure the strength and durability required to handle heavy loads and stack resistance.

The Flat Crush Test is also used and is similar to the Edge Crush Test. Force is applied directly on the surface area of the corrugated fiberboard until the flute flattens and compromises its structure. This test similarly determines the compression and stacking resistance of the corrugated board required to carry heavy loads.

The Burst Test, or the Mullen Test, challenges the durability of the corrugated fiberboard’s surface by determining the force needed to puncture the board.

All of these tests ensure the quality of custom corrugated packaging so your products have the highest level of safety they need to reach their final destination.

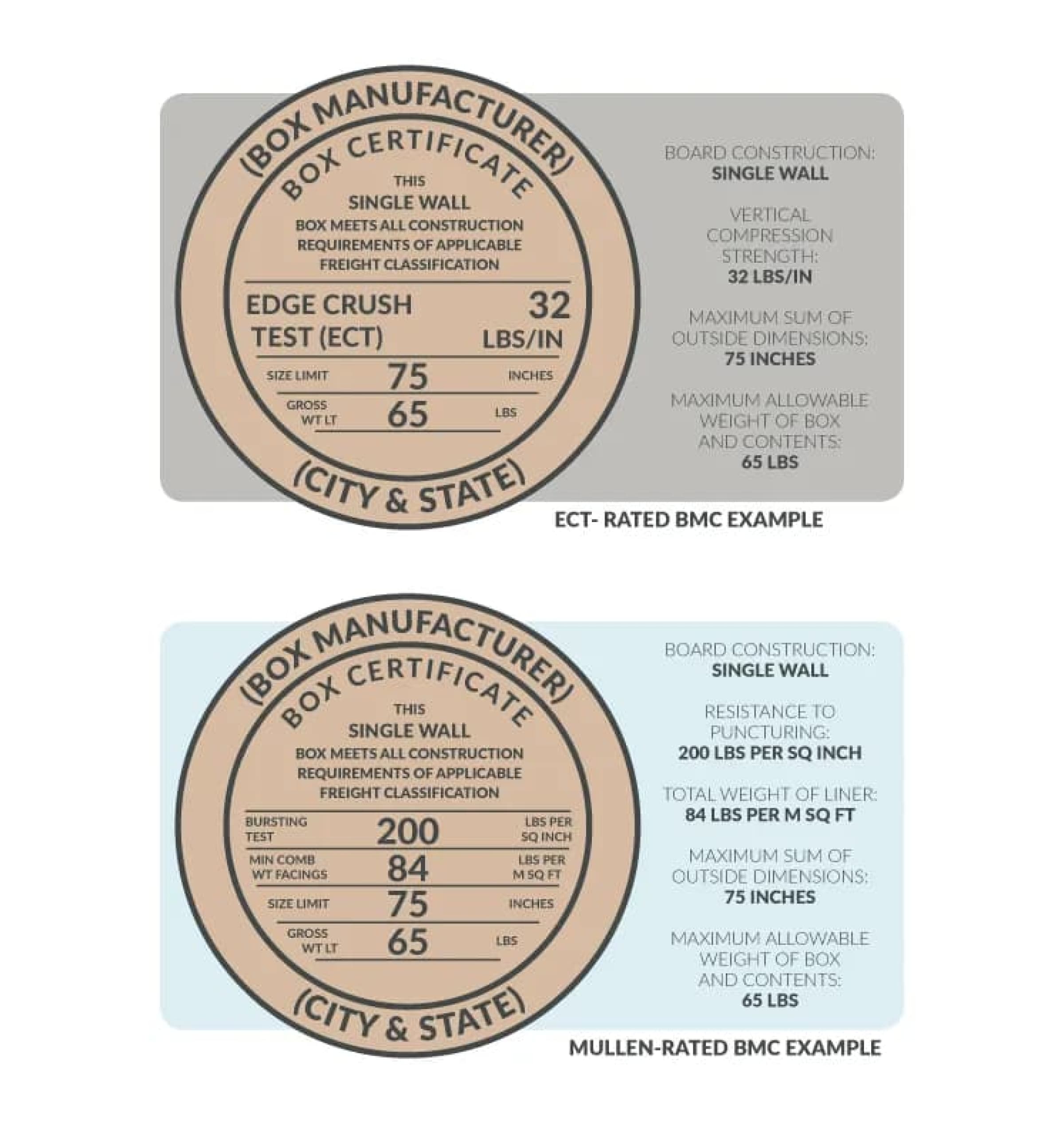

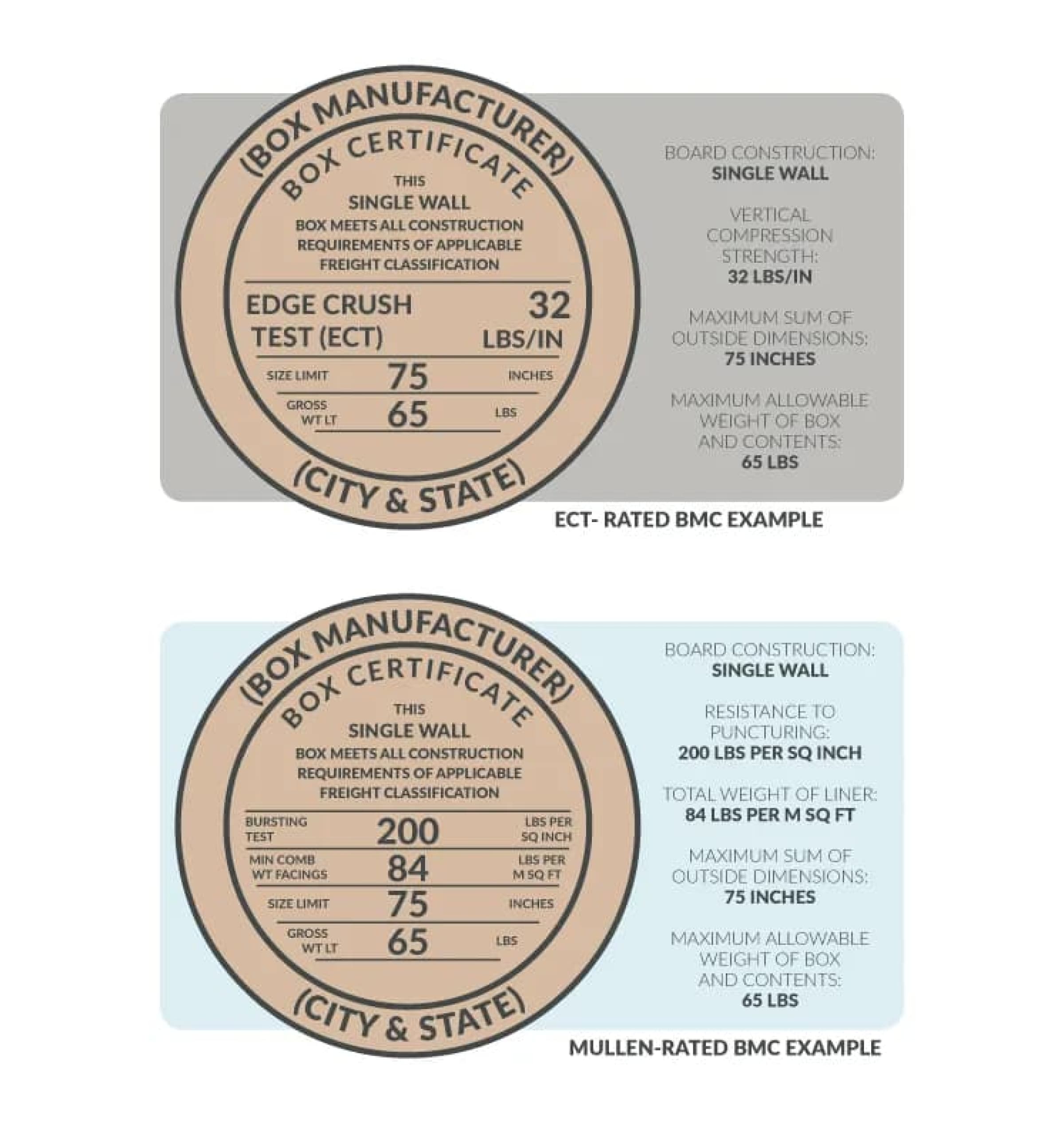

Box Maker’s Certificate

After customizing and thorough testing, the corrugated box is ready for its box maker’s certificate, or BMC! The BMC is a convenient and efficient way of describing some quick specifications about the box, and there are two versions: the Ect-rated BMC and the Mullen-rated BMC.

You will notice a few differences, but these certificates provide the same information:

1. The Box Manufacturer on the outer ring indicates the company responsible for manufacturing your box.

2. Board Construction is the information displayed directly under where it says box certificate. This information tells whether the box is a single, double, or triple wall.

3. Minimum Combined Weight Facings is the total weight of the liner board used before the entire liner board is cut and made into boxes.

4. Size Limit is the maximum outer dimensions of the box. This section is helpful to know for storage and shipping purposes.

5. Gross Weight Limit is the maximum weight allowed for the box and the items within.

6. City and State are located at the bottom of the label. It indicates the location where the box is constructed and shipped.

Benefits of Corrugated Packaging

If you’ve followed along until now, you may already understand some of the benefits of corrugated packaging. Corrugated cardboard and corrugated boxes have seen enduring popularity because of the many benefits they have to offer.

Some of the main reasons for their popularity include:

1. Protection and Durability – Corrugated boxes are one of the best packaging options for those seeking to protect their items during transit. It can handle the impacts of being moved around and shipped, and the cushioning offers much support. These boxes can withstand harsh impacts without damaging products and are an excellent barrier to the elements, making them best for e-commerce packaging.

2. Environmentally friendly – Sustainability has become increasingly important, especially for packaging. Corrugated boxes use recycled fibers, making them a better contender for sustainable packaging alternatives.

3. Customizable – Because of the many options available for raw materials and their environmental-friendliness, corrugated packaging is the best option for those looking for bespoke packaging, including printing. The shape and thickness are easily customizable alongside graphics and surface printing.

But Are Custom Corrugated Boxes Right for You?

Many industries benefit from using corrugated packaging, especially e-commerce. Depending on the size and shape of the packaging, shipping and mailing can be more manageable. However, there are still some drawbacks to this type of packaging.

For starters, corrugated boxes are susceptible to inclement weather, such as rain or snow. The packaging can become deformed or lose its shape.

But the biggest drawback of using corrugated cardboard is its cost. Compared to other options, corrugated is on the higher side of the price range, which may be disheartening for companies with a lower budget. However, many ways exist to reduce costs and create affordable luxury packaging!

Get Started – Choose a Corrugated Box!

Corrugated packaging offers many benefits, particularly in its durability and customizability. With this material, you can have a lot of creative freedom in designing the packaging precisely as you wish while ensuring your product is safe during transport.

If you want to learn more, contact one of our packaging specialists today to begin your next project with corrugated packaging!