Corrugated boxes are the backbone of modern product shipping and e‑commerce, protecting everything from fragile cosmetics to heavy machinery while carrying a brand’s story across borders. For foreign brands, wholesalers, and manufacturers working with OEM partners like XingKun in China, understanding corrugated packaging is the first step to reducing damage rates, optimizing freight costs, and upgrading customer experience.

What Is Corrugated Cardboard Really?

Corrugated cardboard (also called corrugated fiberboard) is a multi‑layer paper‑based material made from at least one fluted (wavy) medium glued between two flat linerboards. This unique “sandwich” structure gives corrugated boxes their high strength‑to‑weight ratio, making them far more protective than simple paperboard or standard cardboard.

The fluted medium forms arches that absorb shock and distribute loads.

The linerboards on each side protect the flutes and provide printable surfaces for branding.

In practice, this means corrugated boxes can handle stacking, transport vibration, and impact far better than ordinary folding cartons made from single‑ply cardboard.

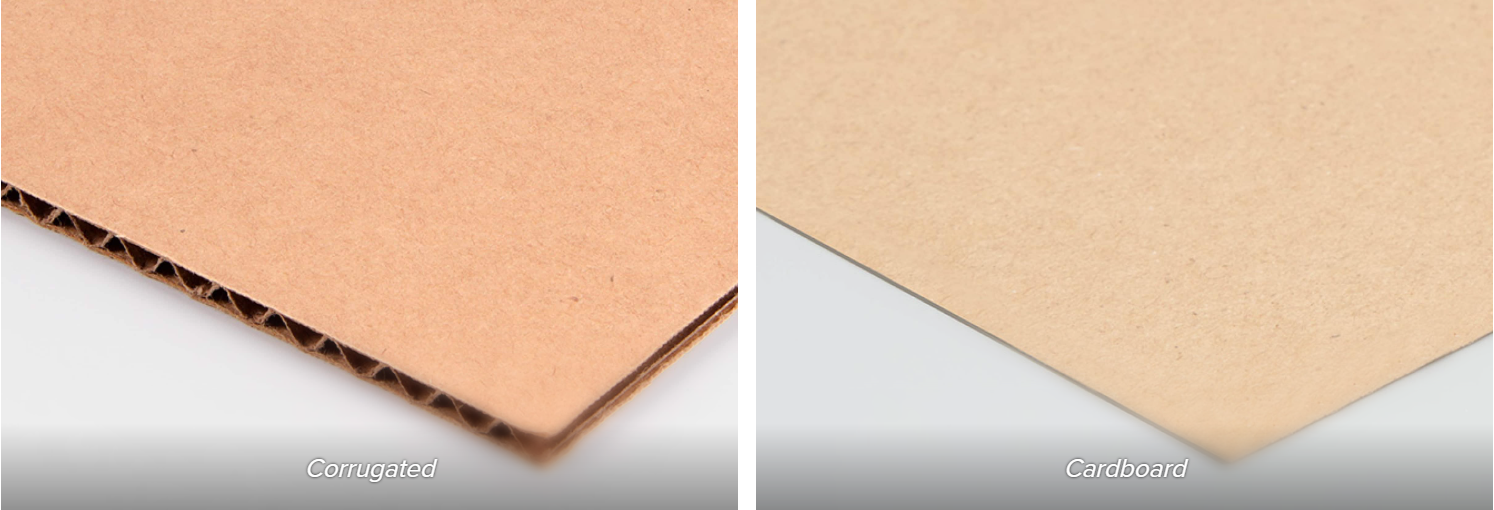

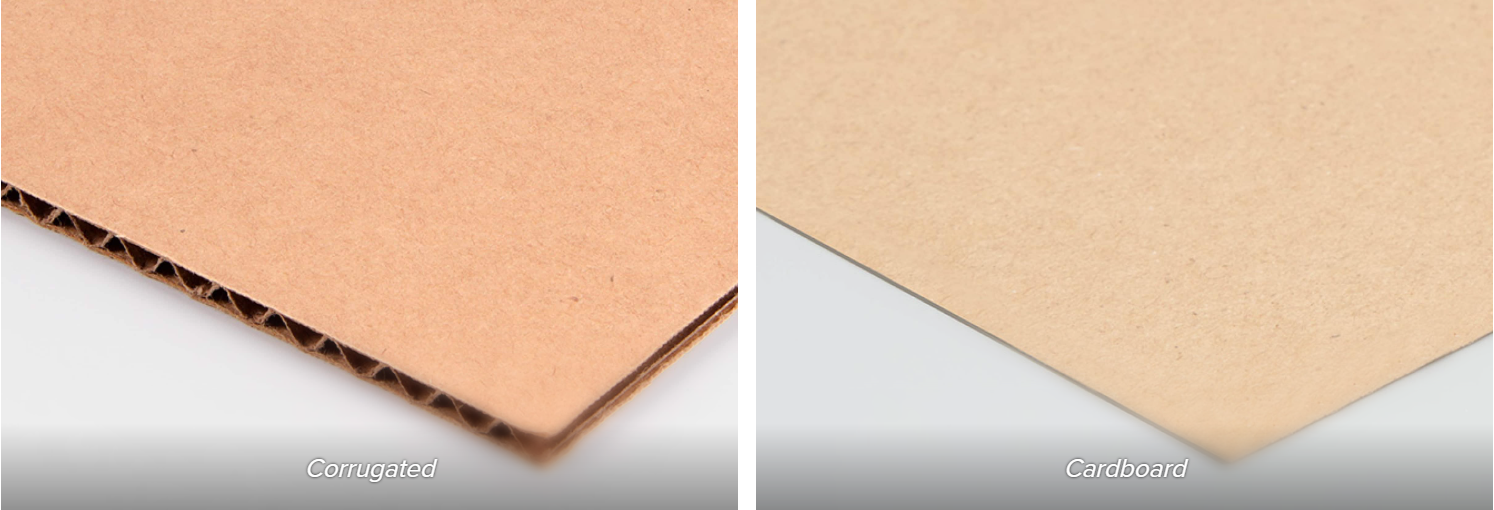

Corrugated vs. Cardboard: What Is the Difference?

Many buyers casually say “cardboard box,” but corrugated box and cardboard box are not the same.

| Aspect | Corrugated Box | Cardboard (Paperboard) Box |

| Structure | Multiple layers: fluted core + linerboards. | Single‑ply paperboard or thick paper stock. |

| Protection | Excellent cushioning, stacking strength, and impact resistance. | Limited protection; suitable for light or inner packaging only. |

| Typical Use | Shipping cartons, e‑commerce packaging, industrial and bulk packs. | Retail folding cartons, sleeves, displays, and inserts. |

| Weight | Light relative to strength, good for freight optimization. | Generally lighter but structurally weaker. |

| Printing | Strong, printable surfaces with many coating options. | Very smooth surface, ideal for high‑end graphics at small sizes. |

For export and cross‑border e‑commerce, brands almost always rely on corrugated outer boxes and may use cardboard cartons inside as secondary or display packaging.

Key Materials in Corrugated Boards

Choosing the right paper combination is critical to balancing cost, print quality, and strength. Most corrugated boards use a mix of virgin and recycled fibers in liners and fluting, customized to the application.

Kraft Liner, Test Liner, and Fluting

Kraft liner

Made mostly from virgin chemical pulp, kraft liner is stiffer, stronger, and more moisture‑resistant than recycled liners. It is ideal for export cartons, heavy loads, and premium printed boxes where brand image and durability matter.

Test liner

Produced with higher recycled content, test liner offers a more cost‑effective but less durable option. It is often used as the inner liner of a corrugated box, where print quality is less important.

Fluting (medium)

The fluted paper can be semi‑chemical (using virgin fibers) or waste‑based fluting made from 100% recycled fibers. Semi‑chemical fluting gives higher strength and better performance in humid environments, while recycled fluting supports sustainability and cost optimization.

XingKun works with different grade combinations (kraft + test + various flute mediums) to match required compression strength, print expectations, and budget for each customer project.

Corrugated Flute Types and Their Uses

The flute is the wavy layer that creates the “corrugated” effect inside the board, directly affecting cushioning, thickness, and stacking strength. Common flute profiles include A, B, C, E, and F, each with a different thickness and performance profile.

Main Flute Profiles

A‑Flute (about 1/4 inch thick)

Provides excellent cushioning and is often used when maximum protection is needed for fragile products. Its larger flutes offer strong stacking ability but a less smooth surface for high‑resolution printing.

B‑Flute (about 1/8 inch thick)

Thinner but very strong, B‑flute offers high puncture resistance and crush strength, and a relatively flat surface for printing and die‑cutting. It performs well in retail packaging, partitions, and small to medium shipping boxes.

C‑Flute (about 3/16 inch thick)

A highly versatile flute used in many standard shipping boxes, with balanced crush resistance, stacking strength, and print quality. It is common for food, glass, and furniture packaging.

E‑Flute (about 1/16 inch thick)

Very thin with a smooth surface suitable for high‑quality printing. E‑flute is often used for retail cartons, luxury printed boxes, and smaller product packaging rather than heavy‑duty shipping.

F‑Flute (about 1/32 inch thick)

Even thinner than E‑flute, F‑flute delivers excellent printability with enough protection for lightweight products. It is common in fast‑food clamshells and specialty retail packaging in some markets.

Combining Flutes for Performance

Double‑wall and triple‑wall boards can combine different flutes (e.g., BC, EB, AC) to optimize both strength and print surface.

AC flute combines two of the most protective flute grades for harsh shipping conditions.

BC flute is a strong all‑rounder for shipping boxes that need high transit protection.

EB flute offers a strong structural core with a fine E‑flute outer face for premium printing.

When brands work with OEM partners like XingKun, these combinations are selected according to product fragility, stacking height in the warehouse, and the shipping route (e.g., sea freight vs. courier).

Types of Corrugated Board Construction

The way liners and fluting are layered directly impacts load capacity, flexibility, and cost.

Single face

One liner glued to exposed fluting, used as protective wrap or cushioning instead of full boxes.

Single wall

One layer of fluting between two liners; this is the most common board for regular slotted cartons.

Double wall

Two flute layers and three liners for significantly increased stacking strength and puncture resistance. Often used for heavier products or where pallet stacking height is high.

Triple wall

Three flute layers and four liners, capable of withstanding very heavy loads and almost acting like a lightweight wooden crate.

For export shipments and long logistics chains, double‑wall and triple‑wall constructions can dramatically reduce damage rates, especially for bulky or fragile items.

Popular Corrugated Box Styles

Different box styles provide specific functions for packing speed, protection, and brand presentation. Many are standardized designs that can be further customized in size, flute, and printing.

Regular Slotted Carton (RSC)

The most common shipping box, with flaps meeting in the center when closed. Efficient for a wide range of products and easy to tape and palletize.

Full Slotted Box

Similar to an RSC but with all flaps the same length, offering extra strength at the top and bottom when overlapped.

Half‑Slotted Container (HSC)

Open at one end; often used with a separate lid, ideal for products loaded from the top or used as storage bins.

One‑Piece Folder / Bookfold

A flat piece that wraps around the product, frequently used for books, frames, and slim products.

Roll‑End Tuck‑Front and Tab‑Lock Styles

Common in e‑commerce and subscription boxes, offering a clean front panel and built‑in locking tabs without needing tape.

XingKun can adapt these styles with custom inserts, handles, or cut‑outs to match each brand’s unboxing experience and fulfillment workflow.

How Corrugated Boxes Are Manufactured

Understanding the manufacturing process helps buyers ask the right questions about quality, lead time, and print limitations.

From Paper to Corrugated Board

Paper Selection

Mills or converters supply rolls of kraft liner, test liner, and medium with specified basis weights and performance grades.

Corrugation Process

The medium passes through heated corrugating rolls that shape it into flutes, while liners are glued to each side to form the corrugated board.

Cutting and Slitting

The continuous sheet is cut and slit into required widths and lengths for different box sizes.

Scoring and Slotting

Machines crease fold lines and cut slots where flaps will form, ensuring accurate folding and consistent box dimensions.

Printing and Die‑Cutting

Flexo or offset presses add branding, product information, and handling symbols before or after board formation, depending on the line setup.

Folding and Gluing

The flat pieces run through folder‑gluers that fold and glue the manufacturer’s joint, creating finished knocked‑down (flat) boxes ready for shipping.

Advanced OEM factories like XingKun also integrate extra finishing such as lamination, embossing, debossing, window patching, perforation, and special coatings to enhance both durability and retail appeal.

Critical Quality Tests for Corrugated Packaging

To protect products and minimize claims, corrugated boxes must pass standardized performance tests. These tests help match a board grade to the required stacking height, handling conditions, and shipping method.

Edge Crush Test (ECT)

Measures the vertical compression strength of a corrugated sample to predict how well a box will stack. ECT values are commonly printed on box certificates and used as a key selection criterion.

Flat Crush Test

Measures how much pressure the flutes can withstand before collapsing, indicating resistance to top‑down compression and rough handling.

Mullen (Burst) Test

Measures the pressure needed to rupture the board, indicating resistance to puncture and rough handling.

For many export applications, brands now specify ECT ratings instead of just board weight, because ECT more accurately reflects stacking performance in real‑world pallets and containers.

How to Read the Box Maker’s Certificate

Most corrugated shipping cartons carry a Box Maker’s Certificate (BMC) that summarizes key technical data at a glance. Understanding this seal helps buyers verify that the supplied cartons meet agreed specifications.

A typical BMC shows:

Board construction (single, double, or triple wall).

Performance rating, such as ECT value or Mullen burst rating.

Minimum combined weight of facings (total linerboard basis weight).

Size limit and maximum gross weight the box is certified to carry under specified conditions.

Manufacturer name and location, indicating who produced the box.

When working with XingKun, overseas buyers can match the BMC data with their internal packaging standards to ensure consistency across factories and markets.

Advantages of Corrugated Packaging for Modern Brands

Corrugated packaging combines protection, cost efficiency, and sustainability, making it the default choice for global shipping and e‑commerce. It offers a rare balance of light weight and high mechanical performance that alternative materials often struggle to match.

High strength‑to‑weight ratio reduces product damage while keeping shipping weight under control.

Excellent cushioning and stacking strength allow safe palletization and container loading for long‑distance transport.

Wide customization range in size, flute, printing, and inserts enables brand storytelling and precise product fit.

Because corrugated is largely paper‑based and widely recyclable, it is also a cornerstone of many brands’ sustainability roadmaps, especially in markets with strict packaging waste regulations.

Disadvantages and Limitations You Should Know

Despite its many strengths, corrugated packaging is not perfect, and understanding its limitations helps avoid costly mistakes in demanding applications.

Moisture sensitivity

Standard corrugated can weaken in high humidity or when exposed to rain, causing deformation and reduced stacking performance. For cold chain, outdoor storage, or maritime environments, additional coatings, plastic liners, or more moisture‑resistant grades may be needed.

Price fluctuations

Corrugated relies on pulp and paper, which are affected by global supply, energy costs, and environmental regulations. This can lead to price volatility that brands must manage through long‑term partnerships and optimized specifications.

Limited reusability compared with rigid plastics or crates

Heavy reuse cycles, especially in returnable transport packaging, may require reinforced designs or alternative materials.

Working closely with an experienced OEM partner allows you to anticipate these weaknesses and adjust board grades, coatings, and structures accordingly instead of over‑ or under‑engineering the box.

Practical Applications of Corrugated Boxes by Industry

Corrugated boxes are used across almost every industry, but the design priorities differ by product type and channel.

E‑commerce and direct‑to‑consumer brands

Focus on unboxing experience, print quality, and courier handling durability. Common features include easy‑open tear strips, return seals, and branded interiors.

Food and beverage

Require food‑safe inks, moisture‑resistant coatings, and strong stacking performance for cold storage and distribution.

Electronics and fragile goods

Rely on custom inserts, multi‑layer constructions, and anti‑static or anti‑scratch materials.

Industrial and automotive components

Often use heavy‑duty double or triple wall boards and reinforced corners for bulk shipments.

XingKun regularly tailors corrugated solutions to these different industries, adjusting flute type, board grade, printing method, and internal fitments for each client’s product line.

Step‑by‑Step: How to Choose the Right Corrugated Box

To align packaging performance with budget and brand goals, buyers can follow a simple decision process when specifying corrugated boxes.

1.Define the product and risk level

Weight, fragility, surface sensitivity, and value per unit.

Tolerance for damage rate (e.g., 0.3% vs. 2%).

2.Map the logistics journey

Number of handling points (factory, consolidator, warehouse, courier).

Transport modes (sea, air, truck, last‑mile).

Storage conditions (humidity, stacking height, storage duration).

3.Select board construction and flute

Single wall for lighter, less fragile products; double or triple wall for heavy items or high stacking.

Choose flute profile (B/C/E etc.) based on cushioning vs. printability.

4.Set performance targets (ECT / burst)

Choose ECT or Mullen values aligned with load, pallet pattern, and stacking height.

Verify that the Box Maker’s Certificate matches those requirements.

5.Decide printing and branding needs

One‑color line art vs. full‑color graphics, inside printing, or special finishes.

Requirements for barcodes, regulatory information, and multi‑language instructions.

6.Prototype, test, and optimize

Order samples and conduct drop tests, stacking tests, and trial shipments.

Adjust board grade or structure based on real damage data and feedback.

With XingKun, this process is often supported by technical drawings, 3D mockups, and pilot runs so overseas customers can validate designs before full‑scale production.

Latest Trends in Corrugated Packaging

Corrugated packaging is evolving rapidly under the influence of sustainability, e‑commerce, and digital printing technologies.

Greener materials and coatings

Brands increasingly ask for higher recycled content, FSC‑certified fibers, and water‑based or low‑VOC inks to meet ESG and regulatory targets.

Right‑sizing and packaging optimization

Data‑driven design reduces void space and filler, lowering freight costs and carbon emissions.

Digital and short‑run printing

Digital presses enable fast design changes, personalization, and regional campaigns without high plate costs.

Omni‑channel consistency

Corrugated packaging now must function both as a shipping container and a brand touchpoint in home, retail, and social media environments.

OEM partners that invest in flexible converting lines and sustainable materials are best positioned to support global brands through these changes.

Why Work with XingKun for Custom Corrugated Boxes?

For foreign brand owners, wholesalers, and manufacturers, choosing a reliable OEM partner in China is as important as choosing the right box structure. XingKun focuses on packaging printing and customized corrugated solutions for international clients, combining design support with stable manufacturing capacity.

Key advantages include:

End‑to‑end OEM service

From structural design and sampling to mass production, printing, and export packing, XingKun provides a complete solution tailored to each product category.

Flexible customization

Multiple board grades, flute combinations, and box styles (RSC, mailer, display, inserts) can be mixed with advanced printing, varnishes, foils, and special effects.

Quality control and testing

Box performance is verified using ECT, burst, and compression tests aligned with customer specifications and international standards.

International communication

Experience with foreign brands and wholesalers means smoother project management, clearer documentation, and better risk control for long‑distance cooperation.

Example FAQs for Corrugated Boxes

1. What is the difference between corrugated boxes and cardboard boxes?

Corrugated boxes use a fluted medium sandwiched between linerboards, giving them much higher strength and cushioning than single‑ply cardboard boxes, which are typically used only for light retail cartons.

2. How do I know which flute type is best for my product?

A‑ and C‑flutes are better for cushioning and stacking, B‑flute offers strong crush resistance and good printability, while E‑ and F‑flutes are ideal for smaller, high‑graphics retail or e‑commerce packaging.

3. What does ECT mean on a corrugated box?

ECT (Edge Crush Test) measures how much vertical compression a board can withstand, indicating how well boxes will stack on pallets and in containers; higher ECT ratings generally mean better stacking performance.

4. Are corrugated boxes environmentally friendly?

Most corrugated boxes are made from renewable fibers and contain significant recycled content, and they are widely accepted in recycling systems, making them one of the more sustainable packaging options.

5. How can XingKun help customize corrugated boxes for my brand?

XingKun offers OEM services including structural design, flute and board selection, printing and finishing options, and testing, ensuring that corrugated boxes match your product protection needs, branding goals, and budget.