Content Menu

● The Rising Role of Packaging in Modern Branding

● What Defines a Professional Packaging Box Manufacturer?

● XingKun’s Edge in Custom Paper Packaging

>> 1. Customization Beyond Standard Sizes

>> 2. Precision Printing and Professional Finishing

>> 3. Sustainable Materials and Practices

>> 4. Quality You Can Trust

>> 5. Reliable Production and Global Service

● Why Paper Packaging Boxes Are the Future of Packaging

● The Process of Manufacturing Custom Paper Boxes

● The Importance of Partnering with a Professional Manufacturer

● Industries XingKun Serves with Custom Paper Packaging

● How XingKun Supports Global Clients

● Future Trends in Paper Packaging Industry

● Frequently Asked Questions

>> 1. What makes XingKun different from other packaging box manufacturers?

>> 2. Can XingKun produce small orders or prototypes?

>> 3. Are XingKun’s materials environmentally friendly?

>> 4. Does XingKun offer international shipping?

>> 5. How long does it take to produce custom paper boxes?

In a world where packaging has become a silent ambassador for brands, choosing the right packaging box manufacturer is more than just a procurement decision—it’s a strategic move that directly influences product perception, customer experience, and brand value. For companies aiming to elevate their market presence, the packaging is no longer an afterthought; it’s the stage where the story of the brand begins.

As the global marketplace grows increasingly competitive, every detail counts. The right paper packaging box not only protects your product but also communicates your brand philosophy before the box is even opened. That’s where a professional manufacturer like XingKun transforms simple paper into a compelling brand expression.

The Rising Role of Packaging in Modern Branding

In today’s consumer-driven landscape, a product’s journey doesn’t start with an advertisement—it starts the moment the customer lays eyes on its packaging. Paper boxes, especially eco-friendly ones, have become essential mediums of connection between companies and their audiences.

Modern consumers seek aesthetics, sustainability, and a tactile experience. High-quality paper packaging not only appeals visually but also speaks volumes about a brand’s responsibility toward the environment. This dual purpose—beauty and ethics—has made custom paper packaging boxes one of the fastest-growing sectors in the packaging industry.

Several trends illustrate this shift:

Sustainability as a selling point: Paper and cardboard packaging are favored for their recyclability.

Minimalist elegance: Brands increasingly choose clean, elegant designs emphasizing texture and craftsmanship.

Personalization: Custom sizes, colors, and printing align packaging with brand identity and customer experience.

E-commerce influence: The packaging must survive shipping while providing a delightful unboxing experience.

What Defines a Professional Packaging Box Manufacturer?

A professional packaging box manufacturer is not merely a producer but a partner in building your brand’s story. The process involves much more than cutting and folding paper. A manufacturer must integrate design, engineering, precision printing, and sustainable materials to create packaging that meets both aesthetic and functional requirements.

Key capabilities of a high-quality manufacturer include:

Advanced printing technology (offset, digital, and UV printing).

Custom die-cutting for unique shapes and inner structures.

Durable yet lightweight paper materials (coated paper, corrugated board, kraft paper).

Rigorous quality control covering strength, color fidelity, and finishing precision.

Flexible production capacity to handle small or bulk orders efficiently.

These elements ensure that every paper box not only fits the product but also embodies the brand’s standards of excellence.

XingKun’s Edge in Custom Paper Packaging

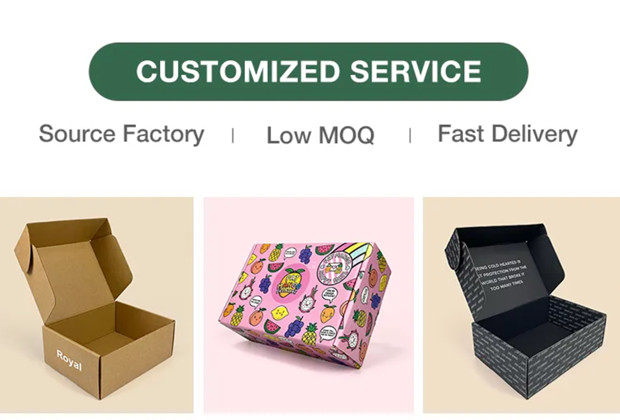

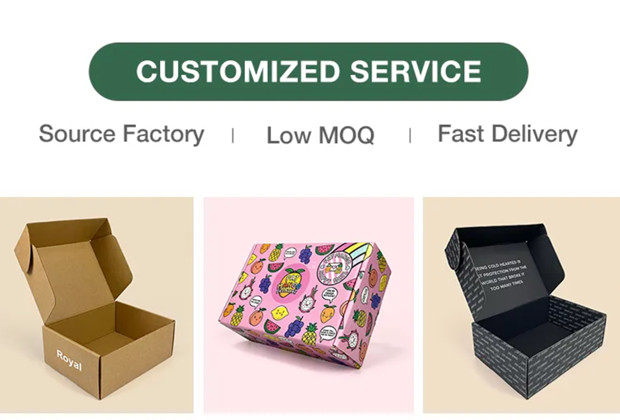

Among the many players in the market, XingKun stands out with an approach rooted in customization, innovation, and reliability. The company focuses exclusively on custom paper packaging box manufacturing, combining creativity with technical expertise.

1. Customization Beyond Standard Sizes

XingKun doesn’t believe in one-size-fits-all packaging. Every product is unique—so should be its box. Whether you need luxury rigid boxes for premium goods, tuck-end boxes for retail display, or corrugated mailer boxes for shipping, XingKun tailors every detail to your exact specifications.

Clients can customize:

Shape, dimension, and structural design.

Color and surface finishes (matte, glossy, embossing, debossing).

Internal inserts and partitions.

Full-print areas to integrate brand graphics and messaging.

2. Precision Printing and Professional Finishing

The look of a package communicates subtle but powerful messages about quality. XingKun leverages advanced printing technologies, ensuring every hue and texture aligns with the client’s brand palette.

Popular printing options include:

CMYK offset printing for bright, vivid visuals.

Spot UV or foil stamping for luxury detailing.

Eco-friendly ink solutions for sustainable brands.

With these capabilities, XingKun transforms ordinary paper into an elegant and durable brand vessel.

3. Sustainable Materials and Practices

Modern consumers value environmental responsibility, and XingKun embraces this philosophy wholeheartedly. The company prioritizes recyclable and biodegradable materials, including FSC-certified paper and eco-friendly inks.

By adopting green manufacturing, XingKun not only reduces waste and emissions but also supports businesses that wish to present themselves as eco-conscious. This sustainable mindset enhances brand reputation and meets the growing global demand for responsible packaging solutions.

4. Quality You Can Trust

Every box produced by XingKun undergoes strict quality checks at each stage—from sample to final shipment. The result is consistent, reliable, and visually appealing packaging that meets international standards.

Their professional quality control team inspects:

Material texture and rigidity.

Print alignment and color accuracy.

Folding structure and adhesive strength.

Final finish and overall craftsmanship.

Quality is not a goal but a habit at XingKun—ensuring your packaging always lives up to your brand’s promise.

5. Reliable Production and Global Service

XingKun’s advanced equipment and experienced production team ensure that orders, whether small-batch prototypes or large-scale runs, are completed on schedule. Moreover, the company’s responsive support staff provides detailed guidance from the initial design stage through to delivery.

The ability to service diverse industries—from cosmetics and jewelry to electronics and food—demonstrates XingKun’s adaptability and global manufacturing reliability.

Why Paper Packaging Boxes Are the Future of Packaging

The shift toward sustainable materials is transforming packaging worldwide. Paper packaging boxes offer numerous advantages over plastic and other materials.

Eco-Friendly and Recyclable

Paper boxes are biodegradable and can be easily recycled, contributing to waste reduction. With sustainability now an essential expectation, choosing paper not only satisfies customers but also aligns with environmental policies.

Versatile and Elegant

From minimalist kraft boxes to high-end laminated cartons, the design versatility of paper enables brands to express themselves through texture, shape, and print details.

Lightweight yet Durable

Despite being lightweight, well-engineered paper boxes offer strong protection. Manufacturers like XingKun use multi-layered paperboard and smart structural design to ensure durability during transport.

Cost-Effective

Paper packaging boxes deliver outstanding visual and tactile qualities at relatively low production costs, especially when done at scale.

This balance of sustainability, versatility, and affordability ensures that paper will remain a preferred packaging material across industries.

The Process of Manufacturing Custom Paper Boxes

Creating a custom paper box involves multiple steps requiring both creativity and engineered precision. XingKun’s process is designed to be seamless, efficient, and collaborative.

Step 1: Understanding the Product and Brand

The process begins with detailed consultation. XingKun studies the product’s dimensions, purpose, and target audience to ensure that the box complements both the product and the brand identity.

Step 2: Design and Structure Prototyping

Designers draft structural layouts and visual mockups. 3D models and prototypes allow clients to visualize their packaging before production begins, minimizing errors and revisions.

Step 3: Material Selection

Clients can choose from a wide range of paper types—rigid board, art paper, kraft paper, or corrugated paper—depending on functionality, durability, and aesthetics.

Step 4: Printing and Finishing

Once the design is finalized, the printing begins. Here, precision machines reproduce vibrant colors, detailed patterns, and fine textures. Finishing processes such as lamination, embossing, and varnishing enhance the final appearance.

Step 5: Cutting and Assembly

Each printed sheet is die-cut, folded, and glued with precision. Structural integrity is verified before boxes move to packaging and shipping.

Step 6: Quality Control and Delivery

Every order passes through multiple inspection points. From the alignment of logos to the strength of adhesive joints, XingKun ensures the final boxes meet high standards before dispatching them worldwide.

The Importance of Partnering with a Professional Manufacturer

Partnering with a reliable packaging box manufacturer like XingKun provides strategic advantages:

Brand consistency: Uniform color tone and structural accuracy reinforce brand recognition across product lines.

Time efficiency: Professional processes and scheduling guarantee timely delivery without compromising quality.

Cost optimization: Efficient production minimizes waste and reduces long-term expenses.

Design innovation: Skilled designers provide unique box concepts tailored to your target audience.

Sustainable value: Environmentally friendly practices enhance brand reputation.

Choosing the right manufacturer turns the packaging from a cost center into a brand asset.

Industries XingKun Serves with Custom Paper Packaging

XingKun’s expertise covers multiple industries, each with unique packaging needs:

Luxury goods: Premium rigid boxes with magnetic closures.

Cosmetics and skincare: Elegant printed paper boxes with protective inserts.

Electronics: Corrugated paper boxes ensuring safety during shipment.

Apparel and accessories: Custom garment boxes and foldable packaging with logo embossing.

Food and beverage: Food-grade paper boxes that maintain freshness and appeal.

Each project benefits from XingKun’s one-on-one design assistance, ensuring packaging that not only fits the product but enhances the overall brand experience.

How XingKun Supports Global Clients

International clients rely on XingKun not only for manufacturing excellence but also for seamless communication and logistics. With an experienced export team, XingKun manages documentation, global shipping, and secure delivery.

Services for international partners include:

Multi-language support for smooth communication.

Rapid prototyping and worldwide sample delivery.

Safe and efficient packaging for overseas shipping.

Strict confidentiality agreements to protect brand designs.

This end-to-end service model allows global brands to partner with confidence, knowing their packaging vision will be executed faithfully and professionally.

Future Trends in Paper Packaging Industry

The future of paper packaging is being shaped by innovation and sustainability. Three major forces define the landscape:

1.Smart packaging: Integration of QR codes and NFC tags for digital engagement.

2.Sustainable materials innovation: Emerging biodegradable coatings and water-based inks.

3.Minimalist luxury: High-end aesthetics achieved with fewer materials and refined craftsmanship.

As a forward-looking manufacturer, XingKun is actively investing in these innovations, ensuring that its solutions remain aligned with both market and environmental demands.

Frequently Asked Questions

1. What makes XingKun different from other packaging box manufacturers?

XingKun focuses exclusively on custom paper packaging, offering full in-house design, premium materials, and sustainable production practices. Every project receives personalized attention from concept to delivery.

2. Can XingKun produce small orders or prototypes?

Yes. XingKun supports both small-batch production and prototyping for clients who wish to test new packaging designs before large-scale manufacturing.

3. Are XingKun’s materials environmentally friendly?

Absolutely. XingKun prioritizes recyclable, biodegradable, and FSC-certified paper, along with soy-based inks, ensuring full eco-compliance.

4. Does XingKun offer international shipping?

Yes. XingKun works with global logistics partners to deliver safely and efficiently to clients around the world.

5. How long does it take to produce custom paper boxes?

Production time varies by complexity and order size. Typically, from design confirmation to final delivery, lead times range between 10 to 25 working days.