Content Menu

● Introduction

● Why a dedicated poker cards manufacturer and supplier matters

>> OEM capabilities and brand fidelity

>> Quality, durability, and global standards

>> Logistics, packaging, and after-sales support

● Production realities and design considerations

>> Card stock, finishes, and feel

>> Printing methods and color fidelity

>> Finishing, packaging, and display integration

>> Security features and personalization

>> Compliance and certifications

● OEM and collaboration for international brands

>> Brand-building through OEM

>> Cross-category opportunities in packaging ecosystems

>> Quality as a differentiator in crowded markets

● Practical steps to engage a poker cards manufacturer and supplier

● Conclusion

● FAQ

>> 1: How can a poker cards manufacturer and supplier support global campaigns?

>> 2: What customization options should I expect from a top poker cards manufacturer and supplier?

>> 3: How important is material certification when selecting a poker cards manufacturer and supplier?

>> 4: What questions should brands ask about lead times and capacity?

>> 5: Can the same partner handle related display and packaging needs?

● Citations

Introduction

In the modern landscape of print, packaging, and promotional goods, choosing a reliable partner for custom poker cards and associated display and packaging solutions is a strategic decision. A strong collaboration with a poker cards manufacturer and supplier can turn brand concepts into tangible, high-quality products that perform across markets. This article explores the key considerations for selecting top poker cards manufacturers and suppliers, with practical guidance for international brands seeking OEM capabilities, consistent quality, and efficient logistics. It also highlights industry dynamics within Sweden and the broader European playing-card ecosystem, offering actionable steps to engage suppliers who can deliver end-to-end services—from concept through delivery.

Why a dedicated poker cards manufacturer and supplier matters

OEM capabilities and brand fidelity

A proficient poker cards manufacturer and supplier translates brand identity into tactile experiences. Beyond just the deck, this includes back designs, card-face styling, tuck boxes, and complementary packaging elements. A capable partner supports end-to-end customization, providing proofs, samples, and iterative feedback loops to ensure that every element aligns with brand guidelines before mass production. This level of collaboration minimizes changes late in the process and safeguards branding consistency across campaigns. The result is a deck that feels uniquely tied to the brand and performs reliably in bulk orders.

Quality, durability, and global standards

For brands that ship internationally, color accuracy, finish quality, and durability matter deeply. A reliable poker cards manufacturer and supplier implements robust quality-control regimes, adheres to recognized safety and environmental standards, and offers reproducible results across production runs. Transparent QA reports and traceability for each batch foster trust with wholesalers and retailers and help all parties meet diverse consumer expectations. The most reputable partners also communicate clearly about tolerances and defect rates, which informs risk management for large launches.

Logistics, packaging, and after-sales support

Effective supply chains rely on predictable lead times, scalable production, and responsive after-sales service. A top-tier partner can align production with marketing calendars, offer flexible packaging options, and provide replacements for damaged units or design revisions when needed. Strong after-sales support reinforces long-term relationships and reduces time-to-market friction for future campaigns.

Production realities and design considerations

Card stock, finishes, and feel

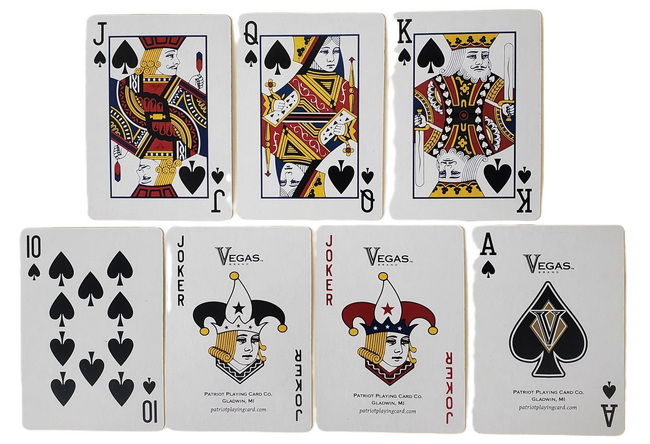

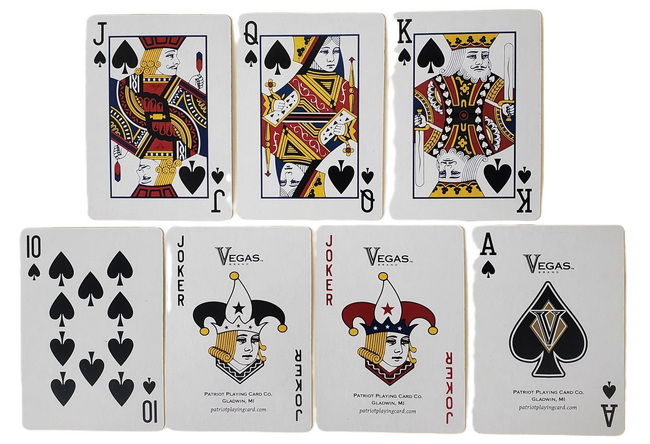

Decks vary in stock type and finish, from linen-textured textures to smooth, plastic-coated surfaces. The chosen material affects handling, shuffling, and perceived quality, which in turn influences consumer impressions and brand perception. A capable poker cards manufacturer and supplier should present a range of stock options and finishes suitable for casino-grade decks, casual promotional decks, and event-specific designs.

Printing methods and color fidelity

Modern production blends multiple printing technologies to balance accuracy, cost, and speed. Offset printing delivers high fidelity for complex designs, while digital printing enables rapid prototyping and shorter lead times. Consistency across batches is essential to maintain brand integrity, especially when multiple decks with the same artwork appear in different regions. A reliable partner ensures color management, ICC profiling, and proofing processes are well-documented.

Finishing, packaging, and display integration

The full value often lies in how decks are presented. Packaging must harmonize with display stands and shelf-ready solutions to optimize retail impact. A proficient poker cards manufacturer and supplier can design packaging ecosystems that reduce retailer assembly time and improve presentation at the point of sale. This integration supports cohesive campaigns and higher in-store conversion rates.

Security features and personalization

For limited editions, promotions, or loyalty campaigns, some brands require serialization, holographic elements, or UV ink features. A skilled poker cards manufacturer and supplier can incorporate these elements without compromising playability or durability, enabling value-added customization for premium markets.

Compliance and certifications

International shipments involve varied regulatory landscapes. A credible supplier provides the necessary certifications, labeling, and documentation to facilitate smooth cross-border movement. This reduces compliance risk and accelerates time-to-market for global launches.

OEM and collaboration for international brands

Brand-building through OEM

OEM partnerships enable brands to sustain a consistent product identity across territories. A robust poker cards manufacturer and supplier offers design support, scalable production, and reliable supply chains that allow brands to execute multi-country promotions with confidence. The outcome is a cohesive deck family that reinforces brand messaging and fosters consumer recognition.

Cross-category opportunities in packaging ecosystems

The synergy between playing cards and related packaging components—such as display stands, labels, and inserts—presents opportunities for bundled campaigns and coordinated retail packaging. Shenzhen-based manufacturers and suppliers are well-positioned to deliver end-to-end services, ensuring seamless integration from card production to display readiness for international clients.

Quality as a differentiator in crowded markets

In competitive markets, consistent quality—covering durability, finish consistency, and color fidelity—serves as a differentiator. Brands that prioritize reliable quality across batches build retailer trust, drive repeat orders, and improve lifetime value. A true poker cards manufacturer and supplier earns a reputation for dependability, which translates into long-term partnerships and scalable growth.

Practical steps to engage a poker cards manufacturer and supplier

- Define precise requirements: Prepare a comprehensive brief covering deck size, stock preference, finishes, back design, packaging concepts, and any security features. Clear specifications reduce iteration cycles and accelerate development, helping teams hit launch windows on schedule.

- Request samples and proofs: Obtain physical samples to assess feel, handling, and durability, and compare them against digital proofs to ensure alignment with expectations. Prototyping at multiple stages minimizes costly rework later in the process.

- Pilot runs and phased ramp-up: Begin with a controlled pilot order to verify production quality, timing, and logistics, then scale up based on learnings. This approach mitigates risk and helps calibrate supplier performance before large commitments.

- Establish clear commercial terms: Lock in price structures, lead times, minimum order quantities, warranty coverage, and return policies. Transparent terms support smooth collaboration and reduce disputes as projects scale.

Conclusion

Selecting a poker cards manufacturer and supplier is a strategic choice that extends beyond sourcing a single deck. It is about forming a collaborative partnership that can translate brand storytelling into tangible products, optimize packaging ecosystems, and synchronize supply chains across borders. By assessing OEM capabilities, production capacity, material quality, and international logistics, brands can identify top poker cards manufacturers and suppliers that support sustained growth, consistent branding, and efficient campaigns. A strong partner provides end-to-end services, rigorous quality assurance, and proactive support, enabling smooth collaboration from concept to delivery and beyond.

FAQ

1: How can a poker cards manufacturer and supplier support global campaigns?

A well-chosen partner offers scalable production, international logistics, standardized quality controls, and flexible packaging options to meet diverse regional requirements and promotional calendars.

2: What customization options should I expect from a top poker cards manufacturer and supplier?

Expect design services for card faces and backs, finishes, packaging customization, security features, and serialization. A premium partner provides proofs, samples, and rapid prototyping to align with brand guidelines.

3: How important is material certification when selecting a poker cards manufacturer and supplier?

Material certifications such as safety compliance and sustainability credentials are critical for international buyers seeking consistency and responsible sourcing across batches.

4: What questions should brands ask about lead times and capacity?

Inquire about monthly production capacity, automation levels, minimum order quantities, and typical lead times for standard versus custom decks to avoid supply-chain disruptions.

5: Can the same partner handle related display and packaging needs?

Yes. Many poker cards manufacturers and suppliers offer integrated packaging, display stands, and promotional collateral to streamline campaigns and accelerate time-to-market.

Citations

[1](https://www.hopesgame.com/news/do-you-know-the-process-of-making-playing-poker-cards.html)

[2](https://www.industryprocess.com/blog/playing-cards.html)

[3](https://dalnegro.com/en/production/)

[4](https://www.youtube.com/watch?v=fXVLOyUZwSM)

[5](https://www.youtube.com/watch?v=XaXN_bfzk00)

[6](https://www.reddit.com/r/Damnthatsinteresting/comments/14sii1i/how_poker_cards_are_made/)

[7](https://www.playingcard-factory.com/news/industry-news/the-production-process-of-playing-cards.html)

[8](https://www.wopc.co.uk/explore/keyword/manufacturing-processes/)

[9](https://www.playingcard-factory.com/news/industry-news/a-stepbystep-breakdown-of-production-stages-in-playing-card-making-machines.html)

[10](https://www.seseprinting.com/products-detail-3371923)